Sustainability with igus®

How sustainable are motion plastics?

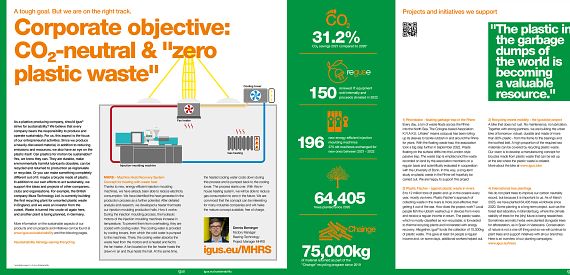

Plastic is a much-discussed material. We know that high-performance plastics can contribute to protecting resources and the environment, and we have made this the focus of our activities. igus Germany's declared goal is to be CO₂-neutral with their buildings and production in 2025. To achieve this goal, they are implementing various measures, some of which are presented on this page.

Service life

Our plastics are optimised for wear. They do not corrode or become damaged by grease and dirt, lasting longer and not having to be replaced often. Our test laboratory enable us to calculate their service life exactly.Find out more about service life

Lightweight

Plastic is lighter than steel and saves weight and therefore energy that has to be applied for movement. In an aeroplane, this amounts to just 4kg if iglidur plain bearings are used instead of metal-rolled bearings.Comparison iglidur vs. metal composite bearing

Energy saving

Our polymers are tribologically optimised and have low friction. This ensures that less drive energy has to be used to move a machine part in an application.How does self-lubrication work?

Predictive maintenance

Our smart plastics product range eliminates surprise machine failure by using sensors to indicate wear so parts are replaced when really necessary and resources are used carefully and rationallyThese are typical features of smart plastics

Replaceable parts

Not having to replace the entire application when wear occurs was crucial when we developed our exchange bearings for linear guides. The rail is not damaged and the bearing housing can be reused. This conserves resources - and results in lower costs.This is how exchange bearings work

Biopolymers

With iglidur N54, we have developed a standard plain bearing that can be used universally and consists of 54% renewable raw materials. The biopolymer bearing is sustainable, and motivates us in our future product development.iglidur plain bearings N54

The igus® spring clean!

As a company we are aware of the carbon footprint that we have on the planet. We have made lots of investments and changes into helping fight climate change but there were some smaller things we wanted to do. We launched “the igus® big spring clean” and we have igus® employees up and down the country taking part in a mass litter picking scheme. This green scheme links nicely with our chainge recycling programme.

Here are a few images of some of the arranged litter picks.

This photo shows the rubbish that was collected around the industrial estate that the UK igus® office is based on. It was quite shocking but very rewarding once we had collected it. We are working in collaboration with Brackmills BID “give back” scheme, which is dedicated to cleaning up Brackmills in various ways.

.png?crop=no&color=ffffff00&w=570)

Even roping the youngsters into the litter picking!! We are very lucky to live in the countryside however this means that people throw litter out into fields where there are animals, so this was an important route for us to clean up! Knowing that the rubbish was being recycled and reused was a massive motivation.

There is a lot of woodland around Brackmills industrial estate and this attracts animals and unfortunately rubbish! As you can see, the igus® crew got well and truly stuck in, clambering through the undergrowth! If you want to do your bit but don’t want to get your hands dirty, why not participate in our chainge programme?

More about sustainability at igus

Sustainable innovations in 2023

3D print filament on sustainable cardboard spool

After the changeover of the iglidur tribofilament i150, the tribofilaments iglidur i151, i180 and i180-BL are now also available on a 750g cardboard spool. Cardboard filament spools have a 50% lower CO2 footprint than conventional polypropylene spools and are much easier for users to recycle.

To the 3D printing filaments

Plain bearings made from 94% renewable raw materials

94% of the new iglidur N94 plain-bearing material is renewable. The material also offers the classic iglidur advantages. It has been optimised for lubrication-free dry operation and allows for precise calculation of service life in plain-bearing applications.

More about the plain bearing N94

PRT slewing ring bearing with regranulate content of at least 97%

In our slewing ring bearing iglidur PRT-02-30-ECO, we use regranulate from our own production. The material combination selected here, iglidur P4 and iglidur M260, work very well together and produce a long service life.

More about the slewing ring bearing made from regranulate

cradle-chain

The first energy chain made from recycled material. Based on the igus Chainge recycling program, the new E2.1.CG catalogue product range was created from recycled material - all tested in the igus laboratory.

More about the cradle-chain

Ball bearings made of regranulate

Our new material xirodur ECO B180 consists of raw materials that have already been used, such as sprue from injection-moulding production, and is processed back into plastic granulate in an in-house process. Finally, production via injection moulding results in an ECO all-rounder in green with recycled inner and outer rings made of dyed xirodur B180 and a cage made from recycled iglidur material.

More about the xiros ECO ball bearing

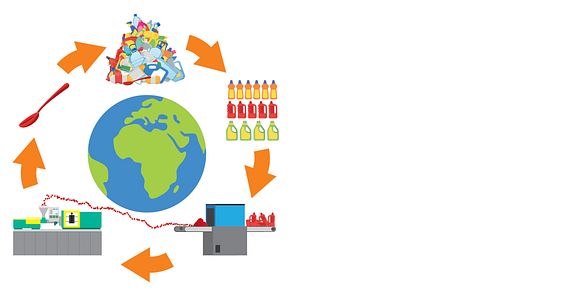

Before: Production of plastics and plastic parts

Energy balance

The production of 1 m³ of plastic requires around 50% less energy than that of 1 m³ of steel or aluminium.

Oil consumption

The production of high-performance plastics accounts for just 0.5% of global oil consumption.Zero Waste

igus UK are dedicated to ensuring zero waste makes it to landfill each year. Through segregation, we strive to create and contribute to a cicular economy of our waste streams wherever possible.99% recycled

99% of our rejects in injection-moulding production (sprues, defective parts) are recycled and returned to the manufacturing process.clean igus

To avoid plastic waste in our production, we have optimised our machines and conveyor belts. We implemented various measures to reduce the waste ratio (production waste + processed material) by 21% in 2021.Find out more about clean igus

Environmental and climate certification

We endeavour to achieve continuous improvements in our environmental and energy management. We are committed to a sustainable corporate strategy with regard to ecological, economic and social aspects. We have summarised these in our energy and environmental policy.ISO 14001 environmental management standard

In order to make our environmental policy transparent and comprehensible, we have been certified according to ISO standard 14001 since 2019, an internationally recognised basis for environmental management systems. This helps us on our way towards a CO2-neutral factory.

Energy management standard ISO 50001:2018

Our energy management system is certified according to international standards. The main goal of the ISO 50001 standard is to help companies improve their energy-related performance by setting up systems and processes.During: Plastics in use

Lubrication-free

Each year, 27 million tonnes of grease pollute the environment. Our plastics require no lubrication.

50% of all lubricants sold worldwide end up in the environment. (Source: M. P. Schneider, 2006)

Global demand for lubricants will increase by 2 % annually, according to forecasts = 45.4 million tonnes in 2019. (Source: The Freedonia Group, 2015)

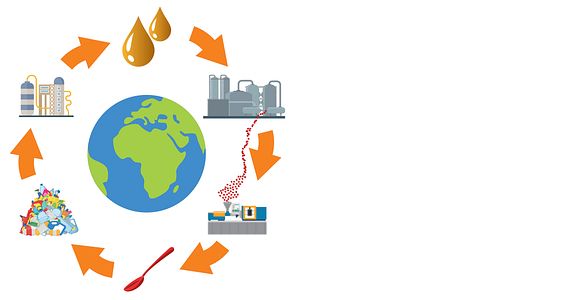

After: Plastics after their use

Chainge recycling platform

We recycle technical plastics - both from igus products and from other manufacturers. We send the material to our production or recycling partners, and you will receive a voucher. As of 6/2023, we have recycled over 80,000kg of material. Our unique platform was awarded the Rhineland Business Prize in the "Sustainability" category in September 2022 and won the Cologne Chamber of Industry and Commerce's "Going Circular" recycling competition in May 2023.Join us and become a chainger!

HydroPRS recycling

We have invested €5 million in Mura Technologie, a company that uses the new technology HydroPRS (Hydrothermal Plastic Recycling Solution) to convert unsorted plastic waste into crude oil within 30 minutes. This conserves resources with pressure, temperature and water. The first industrial site was built at Wilton International in Teesside, UK, and opened on 26th October 2023. It is now commissioned!Find out more about HydroPRS

Recycle industrial plastics now – it's easy

Sustainable action is an important topic that we want to promote in the German economy. To this end, we have created a white paper that explains the most important terms for correct recycling and shows the importance of plastics, including recycled plastics, in Germany. We also present a simple way to recycle technical and industrial plastics and to buy and sell recyclates to complete the circular economy.

Download white paper now

Tree planting

44,470

trees2023

11,001

Trees2022

23,104

trees2020-2021

Our tree-planting projects started in 2020 as Christmas gifts for customers and have since grown into a wide range of reforestation projects - not just in Germany, but worldwide. From saplings to large urban trees, we plant and care for trees and bushes in small and large campaigns. By creating new tree areas, we want to help reduce CO2 pollution in the atmosphere and achieve our self-declared goal of becoming CO2 neutral.

To our tree-planting projects

Resource conservation projects and initiatives

Climate-neutral shipping with UPS

On 1 January 2024, we at igus Germany made our shipping more sustainable and introduced a new shipping option: "UPS Carbon Neutral Shipping". Since then, we have been shipping climate-neutrally with UPS and the CO2 emissions generated by our shipments are offset. This is achieved through recognised, global projects to reduce greenhouse gases, e.g. through the protection of the rainforest in Brazil, wastewater treatment in Thailand or methane recovery in the Netherlands.Our heating concept with waste heat from production

Heating with gas, is that necessary? A lot of heat is generated in the production process, so you have to be able to do something with it? How do we manage to use the waste heat? That's what a team of igus engineers asked themselves and started trying it out. The result: the concept for a heater that uses the waste heat from machines. The plan: to no longer heat any buildings at the company's Cologne site with gas and to make the concept freely available to engineers and mechanical engineers, i.e. to industry. We call it MHRS - Machine Heat Recovery System.Go to the heating concept information page

Plastic Fischer - against plastic waste in rivers

8 to 12 million tons of plastic end up in the oceans every year, mostly via rivers. Plastic Fischer starts right here and collects the rubbish in the rivers, which is more cost-effective than fishing in the sea. How does the project work? Local people use special devices to fish the rubbish out of rivers and receive a regular income in return. The collected plastic waste, which is mostly classified as non-recyclable, is forwarded to thermal treatment plants: it is incinerated with energy recovery. igus finances the collection of a total of 10,000kg of plastic waste. For the duration of the collection, at least 34 people in Kanpur and Mangalore (India) could be given a regular income, and on some days more people are employed.Rhine Octopus ("Rheinkrake") – igus supports a floating waste trap

Every day, a ton of waste floats down the Rhine into the North Sea. That is an enormous amount. K.R.A.K.E., a Cologne-based association ("Krake" is the German word for octopus) has been collecting rubbish in and around the Rhine for years. It took a big step forward in September 2022 with its floating waste trap. Waste floating on the surface drifts into the London-style passive trap. The trap is regularly emptied and the waste recorded on land by association members. The waste is scientifically evaluated in cooperation with the University of Bonn as part of a long-term study on plastic waste in the Rhine.Learn more about the project and the K.R.A.K.E. association (German website)

clean igus – our measures to avoid plastic waste

In the past, new parts from our injection moulding machines often ended up on the floor – and therefore in the rubbish bin – instead of in the collection containers. Waste accumulated due to the large production numbers and the many machines. Optimising our machines and conveyor belts in various ways enabled us to reduce the waste rate (production waste + processed material) by 21% in 2021: Gaps at junctions were closed with magnetic foils, machines and collection boxes were fitted with metal sheets and covers or lids, and conveyor belts were centred and fixed in place; brushes and guide plates now steer parts into the right path, and floor markings and stop wedges ensure the right position.

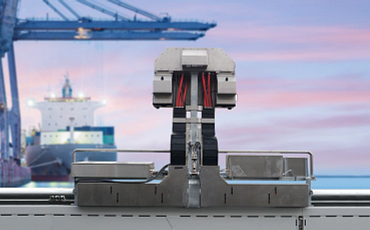

Combating pollutant emissions in container ports with shore power

Running diesel generators of container ships in port are a serious problem. They release fine dust, nitrogen and sulphur oxides as well as CO2 emissions into the environment and atmosphere by the tons. In 2022, we created iMSPO, a mobile socket that allowed container ships to be supplied with shore power easily, quickly and, above all, in a flexible way. If it is also "green", the path to the "zero-emission port" is clear.More about shore power supply for container ships

igus Germany

Re-cooling system for the extruder saves 60% water

Extruders for bar stock production require cooling to work flawlessly. For this purpose, cold water runs through the machine. It heats up in the process, and until recently, it was discharged into the sewage system. This has changed with the re-cooling system: after passing through the machine, the water is cooled down in a cooling tower, stored and can be used again to cool the machine. We also use such re-cooling systems for our injection-moulding machines.