Durable, low-maintenance gearbox solution and energy supply systems in an ice cream vending machine

When summer temperatures prompt cravings for ice cream, vending machines across the country provide us with cooling creations. The sec°mat IC One, made by Bochum-based Seco Manufaktur, turns the sales process into an event. The next-generation ice cream vending machine features our Apiro robot kinematics, not only for durable, low-maintenance operation, but also for user experience.

Profile

- What was needed: A flexible, economic automated solution for ice cream dispensing

- Requirements: Fast ROI, longer maintenance intervals, durability, low error rate

- Material: Apiro modular gearbox system, E2 e-chain, chainflex cables

- Industry: Vending machinery

See all products for vending machinery

Problem

Finding cost-effective robot kinematics that are flexible,durable, and maintenance-free and that people enjoy watching at work – that was the problem to be solved. The developers had initially considered a SCARA robot. "But it turned out that the error rate over time is quite high if this set-up is not in a factory where it can be maintained constantly," says Seco Manufaktur CEO Frank Kuhn. "But longer maintenance intervals and durability were particularly important to us."Solution

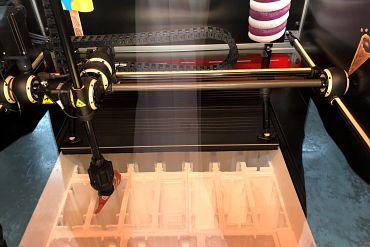

igus experts were involved in the development process, and together they found the perfect solution in the modular drygear Apiro gearbox system. The focus is on tribologically optimised worm gears. The corrosion-free, chemically-resistant high-performance polymers ensure high stability, low weight, a long service life, and no maintenance. The joints are attached by means of a multi-functional profile made of aluminium. This allows drive shafts to be inserted through a hollow space in the middle, facilitating the action of the inverted worm gear, which causes the aluminium profile to rotate. It is thus ideally suited for use in robotics and rotating applications. The linear-movement worm gear allows the aluminium profile to travel linearly, or the worm gear travels on the linear profile. All worm gears have very little clearance. In addition to the three-axis linear robots, the sec°mat's final complete system has two E2-series energy chains and chainflex cables. "It is not only technically optimal, but also an eye-catcher," says Kuhn. "The ice cream is retrieved where the customer can see the process, since we weren't interested in a coldly industrial solution. We wanted the system to be visually attractive and arouse user curiosity."

Further information

Apiro modular gearbox system

Implement individual applications cost-effectively with the drygear Apiro modular gearbox systemFind out more now

Products for vending machinery

Plain bearings, linear guides, energy chains, and drive modules for fully automated systemsDiscover now