Lubrication- and maintenance-free components for the autonomous robo kitchen

Profile

- What was needed: various slide, joint and linear bearings, energy chains for rotary and 3D movements

- Requirements: free from external lubrication, low maintenance, long service life, cost-effective, short delivery times

- Industry: Vending machinery

Problem

Control the ingredient containers, tip a weighed amount into the saucepan or mixer and deliver the ready-to-serve dish to the customer: there is a lot of movement in the kitchen cell. And to ensure that it runs smoothly, cleanly and safely, RoboEatz's designers were looking for energy supply systems, bearings and drive components that are suitable for food processing and do not require external lubrication. A long service life with simultaneous cost savings and the use of series parts with short delivery times were also required. It was also important to the RoboEatz founders to work with as few global suppliers as possible.Solution

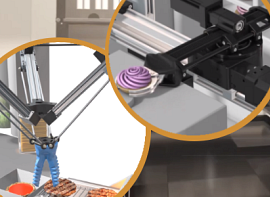

The developers relied on igus' long-standing robotics and automation expertise. A variety of motion plastics are used for the many different movements, which meet the requirements regarding durability, lubrication and cost savings. For example, dry-running igubal fixed flange bearings and rod ends are responsible for the pivoting movement of the wok and ingredient boxes, thereby enabling self-alignment. iglidur MCM clip bearings are also used as shaft guides in sheet metal connections. The linear movements of the individual axes, for example on the containers, are carried out using drylin linear technology. drylin SLW linear modules ensure a safe design for grippers; the gripper arm opens and closes by means of a reverse lead screw. With a rotation angle of 360° in the first axis of the robot, an RBR energy supply system reliably guides energy and signal. And finally, a triflex energy chain with retraction system is mounted on the robot arm, which significantly increases the service life of the cables in three-dimensional movement.

More information

Low Cost Automation for the catering industry

Lubrication-free, lightweight components with fast return on investmentDiscover now

Products for vending machinery

Plain bearings, linear guides, energy chains, and drive modules for fully automated systemsDiscover now