Reliable despite dirt, vibrations and humidity

Reliable in combination with dirt, vibrations, low temperatures and heat

Conditions in agricultural engineering are rough and temperamental. Therefore, it is even more important for components to work reliably and withstand the daily conditions. Our technical products can do that: low temperatures, heat, ice and dirt simply do not faze them. Their high-performance polymers and without additional lubrication, they have been designed especially for this.Maintenance-free polymer plain bearings can be used with heavy-duty applications in soil cultivating machines or front loaders. drylin® linear systems can adjust monitors in tractor cabins. Energy chains and chainflex® cables are ideal for supplying field spraying systems with energy and liquids. Application options are versatile.

Would you like more information about the range of products suitable for agricultural engineering? Our experts will be happy to get in touch with you.

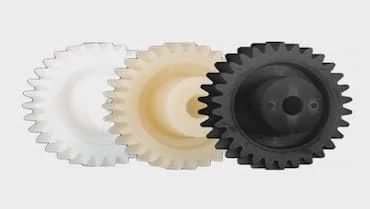

Selected motion plastics for agricultural engineering

iglidur® plain bearings

- Resistant to edge pressures

- Lubrication-free, corrosion-free, resistant to dirt

- UV-resistant and vibration-dampening

- Find out more information

igubal® spherical bearings

- Corrosion resistance

- Maintenance-free and self-lubricating

- Chemical resistance

- Find out more information

drylin® linear technology

- Dirt-resistant

- Lightweight and quiet operation

- Simple installation and maintenance-free

- Find out more infotrmation

E2/000 e-chain® series

- Fast assembly

- High strength and quiet operation

- Various fastening options

- Find out more information

Individual components ...

Cabin

Suitable products:

Mirror adjustment: iglidur® J plain bearings

2Monitor adjustment: drylin® W guide carriages

3Seat back adjustment: drylin® W linear guides

4Steering column: iglidur® G plain bearings

5Control elements: triflex® Robotic energy chain

6Hydraulic valve connection: igubal® double joints

7Seat back adjustment: drylin® W linear guides

8Arm rest adjustment: drylin® W linear guides

9Seat adjustment: E2 energy chain and chainflex® cables

Use igus® products in agricultural engineering

Mulching mower

Applications in use in the agricultural industry

No more wasting time with lubricating bearings

igus® has been successfully collaborating with Lemken since 2008. Various Lemken machines are equipped with igus plain bearings, among them the cultivator Karat 9. In the overload elements, the metal bearing points previously used had to be lubricated up to one hour per day to prevent wear and corrosion. By switching to lubrication-free polymer plain bearings, the farmer saves valuable time. Furthermore, the dirt resistance and stability of the plain bearings increase service life and dependability.

Heavy load up to 15 tons is made possible

Maintenance-free and resistant to dust and dirt, the iglidur® G plain bearings are used in hinges, locking systems and hydraulic cylinders of bale trimming machines from Optimal-Vertrieb Opitz. They replace red brass solutions, that were produced in-house and required both a relatively large installation space and lubricants that polluted the environment. The new polymer bearings need no lubrication and withstand all edge loads without problems.