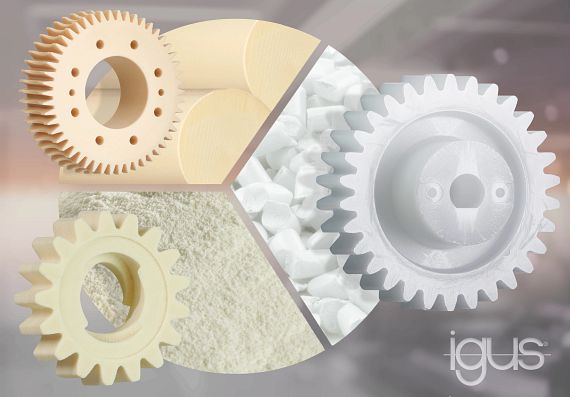

Wear-resistant plastic gears

From a single part to high-volume production of up to several million

Plastic gears made of iglidur® high-performance polymers enable lubrication-free and maintenance-free use.Thanks to their special combination of base polymers, fibres, extenders and solid lubricants, they are extremely wear-resistant. Our plastic gears have already successfully proven themselves in different applications.

iglidur® materials are thoroughly tested in our own Testlab.

In accordance with the predominant parameters in your application, we provide you with free, non-binding advice on the right materials and manufacturing and tool technology needed to form your individual gears (toothed component) in a reliable process.

You can place an order with igus® with no minimum order quantity.

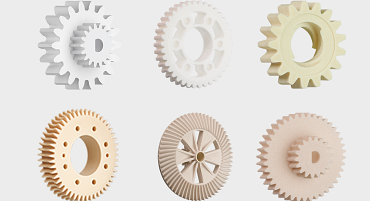

Browse all plastic gear types

Bevel Gears

.png?crop=no&color=ffffff00&w=370)

- Gear ratio: 1:1 - 1.5

- Module: 1 - 3.5

- Low coefficient of friction

- Low moisture absorption

- Find out more

Spur Gears

.png?crop=no&color=ffffff00&w=370)

- Number of teeth: 12 - 150

- Module: 0.5 - 3

- Increased wear resistance

- Good tribological specifications

- Vibration-dampening

Gear Racks

.png?crop=no&color=ffffff00&w=370)

- Module: 0.5 - 3

- Length: 250mm

- Low coefficient of friction

- Low humidity absorption

- Find out more

Your bespoke gear

From a individual part to high-volume production

We have many different ways of manufacturing the bespoke gear you need. We can advise you regarding the most technically and economically efficient manufacturing method and will also recommend the suitable plastic material.We get lots of customers needing bespoke gears and can help you with yours!

Download the gear checklist

Need us to call you?

Request a bespoke gear design

Our manufacturing procedure for plastic gears

Injection moulding gears

- From our largest possible variety of iglidur® materials

- Standard dimensions available

- Different shaft-hub combinations available

- Individual high-volume production of special parts

- Economic high-volume production

- Matching racks available.

3D printed gears

- Delivery time from one to three days

- No minimum order quantity

- CAD configurator for gears and racks online

- For prototypes

- Custom designs available.

- Various mateiral options.

- High wear rate

Mechanically manufactured gears

- Made of iglidur® bar stock

- Economically efficient in the case of small to medium-sized quantities

- For high-volume gears

- Various materials to choose from

- FDA options available.

- Custom design options

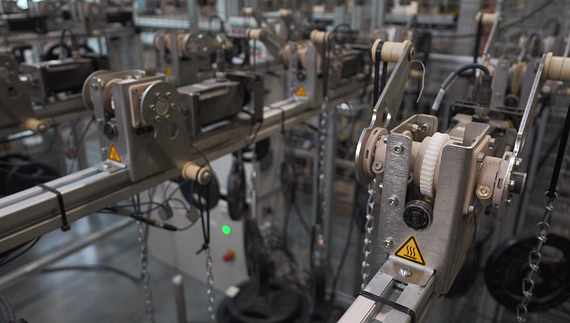

Application examples with plastic gears

Gears in the automotive industry

The proportion of electronic and electromechanical components in vehicles has been growing continuously for years. The increased comfort and the growing safety requirements promote this development. The cable harness, which is responsible for supplying all these components, is the second-heaviest component in many motor vehicles, right after the engine. Actuators make up a large share of the elements to be supplied with power and signals.

Plastic gears in rail technology

To reduce interruptions of rail journeys, track switches are used. They ensure the seamless transition of the rail vehicles from one track to another. Reliable track switches are fundamental for a smooth operation of passenger and freight transport.

Plastic gears in e-bikes

E-bikes are becoming increasingly lighter and in addition very quiet. During operation, there are hardly any motor noises to be heard. However, resourceful inventors, such as Lars Hartmann from Reichshof, are not content with that. The bicycle chain's background noise was too loud and a thorn in his side. A metallic chain sprocket served as a guide roller for the chain to prevent it from colliding with the frame, but caused tremendous operating noise. In search of a remedy, he remembered the offer by

igus, which he had seen at a trade show: the 3D printing service , which manufactured individual components cost-effectively with a 3D printer.

Polymer gears for the charging system of electric cars

Easelink, a company from Graz, has developed "Matrix Charging", a charging system consisting of two components. A charging pad connected to the mains is installed in the car park. A connector on the bottom of the e-car drops down when the car is parked over the pad. The charging process starts automatically, without the driver having to connect a cable - similar to inductive charging, but with up to ten times the charging power and with 99 per cent efficiency.

Plastic gears in the fire brigade

The on-site fire brigade of Fraport AG provides for fire safety at the airport in Frankfurt am Main. Its airport fire engines have roof-mounted water cannons which use a servomotor to change the angle of the spray nozzle. As this angle is also changed while water is being sprayed, the load on the servomotor is considerable. After being in use for ten years, the gears in the cannon have become worn and therefore the roof-mounted cannons must be repaired.

Why we developed our plastic gears

iglidur® gears have proven their worth in different gearboxes and have also been tested under realistic conditions of use in the igus test laboratory. For example, torque fluctuations, efficiency and backlash of the gearboxes with plastic gears are electrically measured and evaluated. The gathered empirical values allow for continuous optimisation of our plastic gears and use in wear-intensive continuous application.iglidur® gears are characterised by their special wear resistance in use. Due to their special material composition of base polymers, fibres, fillers and solid lubricants, they have very low wear properties and do not require additional lubricants. This extends maintenance intervals and reduces expensive downtime minutes.

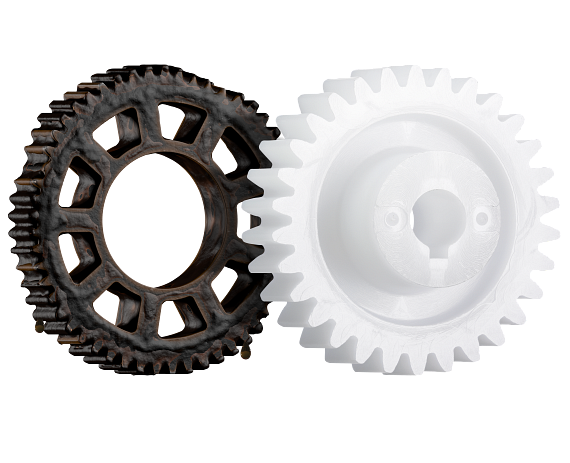

Plastic gear instead of metal gear

Tech up and cost down - now

Plastic gears are cost-effective, do not require external lubrication and are maintenance-free.In contrast to metal gears, our polymer ones contain solid lubricants, which reduce friction.

Furthermore, certain fillers ensure an additional

improvement of the mechanical properties.

Overview of benefits

- Lubrication-free

- Maintenance-free

- Lightweight

- Noise-reducing

- Corrosion-free

Frequently asked questions about plastic gears

What is a plastic gear?

A plastic gear is a round component that has uniformly distributed teeth around its circumference. It transfers force between two rotating gears or between a gear and a rack. Depending on the application, further types are used.

What kinds of pinion gears are there?

The most common kinds of pinion gears are:

• Spur gears (you can find them in our online shop)

• Racks

• Worm gears

• Bevel gears

Different kinds of gear and toothing are often combined with each other in order to implement certain sequences of movement.

How are the pinion gears made from plastic?

At igus®, gears are made with the help of three manufacturing methods:

• Injection moulding with iglidur® granulate materials

• Mechanical processing with iglidur® bar stock as the material

• 3D printing with iglidur® SLS or FDM materials

Depending on the enquiry, we will advise you on manufacturing methods and work with you to find the best economical solution – free of charge, no strings attached.

Further information on our materials used in gear pinions

Request your free sample today.

If you would like to order a free sample or sample box to try, please do so and discover more about the iglidur® gears.

Largest test lab in the industry

We carry out tests so that you do not have to experiment. Find out how our iglidur® polymer plain bearings are tested in the largest test laboratory in the industry. We also carry out individual customer tests here.