Clearance- reduced pre-loaded lead screw nuts

Minimum axial clearance

Clearance-reduced pre-load lead screw nuts

The pre-load lead screw nut convinces with minimal axial clearance and highest positioning accuracy. It is the cost-effective alternative to the zero backlash lead screw nuts and perfectly suited for small pitches. This is the proven preload principle from SHT-PL.► Permanently minimal axial clearance for high positioning accuracy

► More cost-effective than ZB nut due to fewer components & injection moulding

► Reduced axial clearance due to spring pre-load on the lead screw nut

► No lubricating grease or oil in the lead screw drive

Reduce the time required for your design and optimise the procurement process for your lead screw technology.

Discover in the online shop

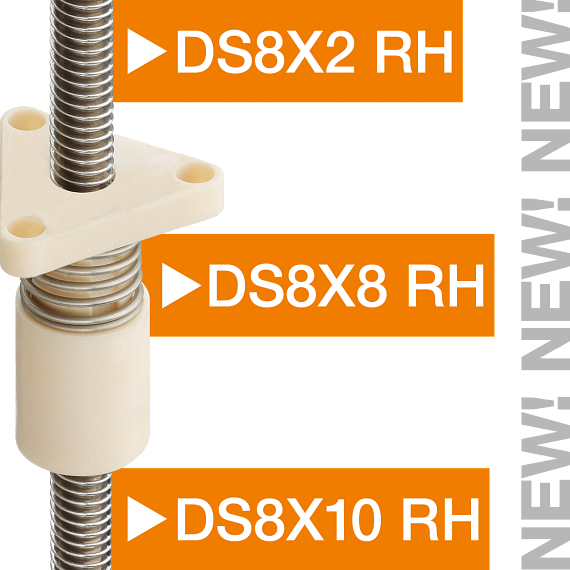

Product range

Maximum positioning accuracy

| DST-JFRM-PL-0001-DS8X2 | DS8x2 | ||||||||

| DST-JFRM-PL-0001-DS8X8 | DS8x8 | ||||||||

| DST-JFRM-PL-0001-DS8X10 | DS8x10 |

▲ Permanently minimal axial clearance for high positioning accuracy

▼ More cost-effective compared to the ZB lead screw nut due to fewer components and injection moulding manufacturing process

■ Reduced axial clearance due to spring preload on the lead screw nut

● No grease or oil in the lead screw drive

The dimensions of the new dryspin® pre-load lead screw nut at a glance

Further important information:

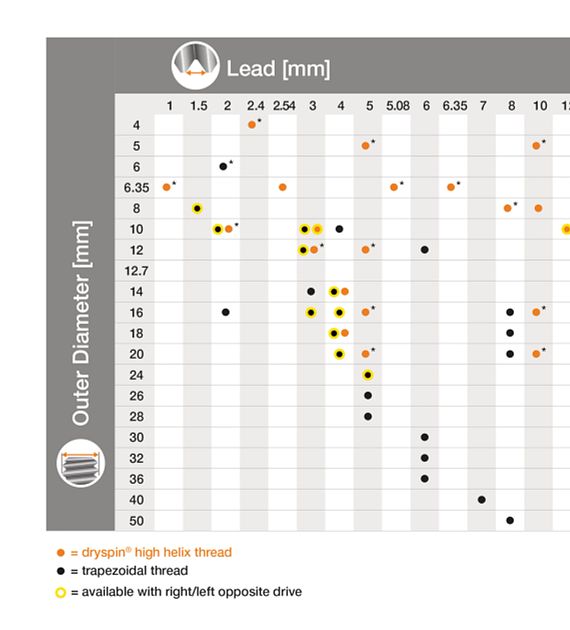

The dimensions of the dryspin® lead screw drives

Everything at a glance and sorted by specifications

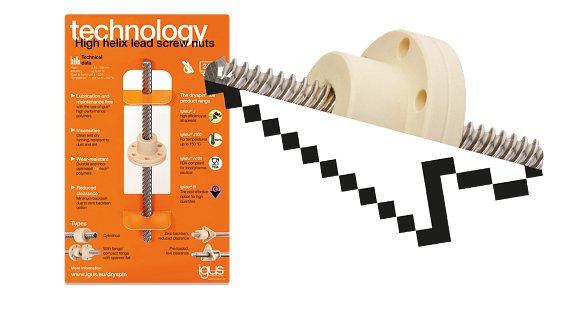

Six different types of lead screw nut made of seven different materials with individual specifications are available. Suitable lead screws are available in high helix, trapezoidal and metric threads and in stainless steel, steel and aluminium. We have clearly presented all dimensions for you.

► Diameters from 4 to 50mm and pitches from 0.5 to 100mm

► More than 5,000 variants in the standard product range

► Different materials and types

► Our experts will be happy to help you choose

► Diameters from 4 to 50mm and pitches from 0.5 to 100mm

► More than 5,000 variants in the standard product range

► Different materials and types

► Our experts will be happy to help you choose

Go to dimensions table

Are you looking for the right lead screws?

Here you will find all the necessary information

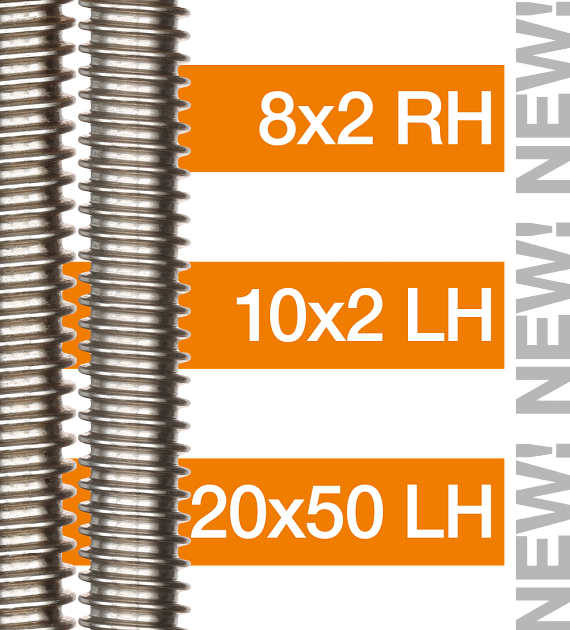

Of course, we have expanded our dryspin® lead screw product range not only with the new lead screw nuts, but also with the matching lead screws.

The dryspin lead screws offer numerous advantages:

► 100% corrosion-free

► Quiet operation due to rounded tooth geometry

► Up to 30% longer service life due to thread asymmetry

► And many more advantages

The dryspin lead screws offer numerous advantages:

► 100% corrosion-free

► Quiet operation due to rounded tooth geometry

► Up to 30% longer service life due to thread asymmetry

► And many more advantages

Discover the matching lead screws here

What should you do in the event of unwanted axial clearance?

Pre-load lead screw nut with dryspin® thread

Axial clearance - what exactly is it? How is it defined and what needs to be considered?The question of clearance is often asked in the case of plastic lead screw nuts. This describes the lost motion, i.e. the "dead travel" on the lead screw. Or in other words the gap between the thread flanks of the lead screw and the lead screw nut. The term clearance is often used in general. In this context, the correct technical term is axial clearance. It outlines the movement of the lead screw nut in the axial direction without movement of the lead screw. Lead screw drives require a minimum clearance to maintain their function. If the axial clearance is too small, the torque required to move the lead screw nut also increases.

What I have to bear in mind:

In addition to the axial clearance caused by the manufacturing tolerances, the application-specific influences must also be taken into account. In addition to thermal and hygroscopic environmental influences, the minimum clearance to be considered in the application must also take into account the friction heat generated by the application. This plays a decisive role in connection with the expansion behaviour of the polymer material used. This means that the axial clearance in the system can change with temperature fluctuations.

How can I reduce the axial clearance?

In addition to the right choice of material, a preloading mechanism has proven to be an effective measure to reduce unwanted clearance. For our dryspin® high helix threads and trapezoidal threads there are four versions with pretension: Zero-Backlash, Preload, Low-Clearance and AB lead screw nut.The working principle of the pre-load lead screw nut

PL lead screw nuts reduce the axial clearance in a lead screw drive by preloading two lead screw parts with a compression spring. The spring pushes the two halves of the lead screw nuts apart axially in the direction of the lead screw flanks. As long as the axial load in the lead screw drive is lower than the spring pre-load, the entire lead screw drive has a minimised backlash. This also permanently reduces clearance caused by wear.

Potential application in medical technology

Lubrication-free operation and high precision are very important, especially in medical technology. Due to the low-clearance and cost-effective function of the PL lead screw nut, numerous advantages can be achieved for both horizontal and vertical movements:

- Clean operation due to lubrication-free and maintenance-free properties

- Minimum axial backlash without readjustment

- Precise positioning and infeed movements

- Smoother operation and fewer vibrations thanks to the combination of the dryspin® thread profile and the pretension of the lead screw nut

Try out dryspin® technology for yourself

With the help of the free lead screw sample

Holding a real sample in your hands is an important part of understanding your component. We will be happy to send you a sample of our dryspin lead screw drives for this purpose. We have summarised all the specifications and advantages of dryspin lead screw technology in the sample for you. See for yourself and if you have any questions, our experts will be very happy to help.Request free lead screw sample here