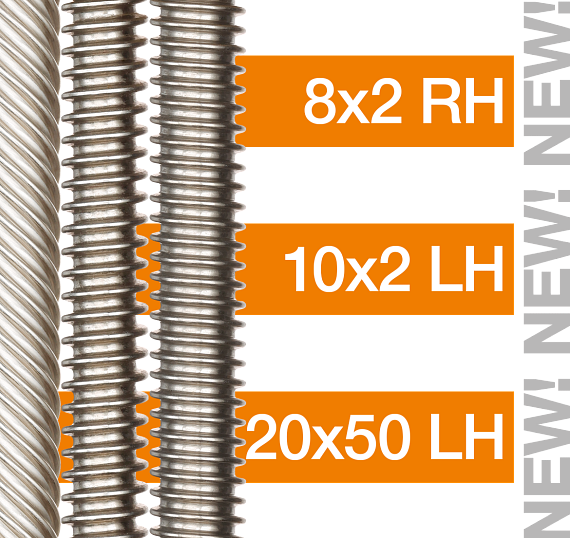

New dryspin® dimensions added to the high helix lead screw range

Smooth, quiet, long service life

New dryspin® dimensions: extension of the sliding and high helix thread product range

The high helix lead screws are part of our dryspin® range, which is specifically designed for fast and very efficient applications. Here, thread sizes from DS4x2.4 to DS18x100 are available. The lead screw product range also offers small pitches with the well-known dryspin® advantages.► Vibration-free and quiet operation

► Lead screw machining online without previous CAD knowledge

► Service life of lead screw drives predictable online

► Desired length without waste

► Up to 30% longer service life due to thread asymmetry

Discover in the online shop

Savings with lead screws: technical data and product range [mm]

All dryspin® lead screws can be custom machined. Please configure this online or send us your drawing. We can then provide a quotation quickly.| DST-LS-8x2-R-□-ES | ||||||||

| DST-LS-10x2-L-□-ES | ||||||||

| DST-LS-20x50-L-□-ES |

▲ Quiet operation due to rounded tooth geometry and longer service life due to asymmetry

▼ Up to 30% longer service life due to thread asymmetry

■ Ongoing test series in the internal test laboratory

● Lubrication-free operation and easy cleaning thanks to corrosion-free AISI 304 stainless steel

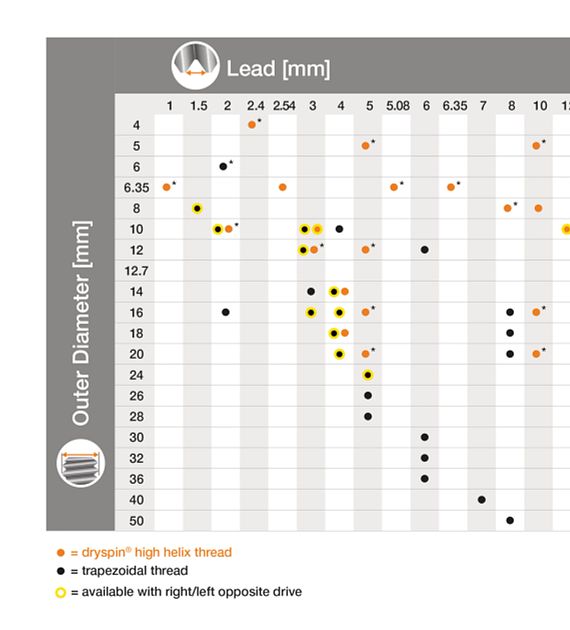

The new dimensions of the dryspin® high helix lead screws at a glance

Further important information:

The dimensions of the dryspin® lead screw drives

Everything at a glance and sorted by specifications

Six different types of lead screw nut made of seven different materials with individual specifications are available. Suitable lead screws are available in high helix, trapezoidal and metric threads and in stainless steel, steel and aluminium. We have clearly presented all dimensions for you.

► Diameters from 4 to 50mm and pitches from 0.5 to 100mm

► More than 5,000 variants in the standard product range

► Different materials and types

► Our experts will be happy to help you choose

► Diameters from 4 to 50mm and pitches from 0.5 to 100mm

► More than 5,000 variants in the standard product range

► Different materials and types

► Our experts will be happy to help you choose

Go to dimensions table

Are you looking for the right lead screw nuts?

Here you will find all the necessary information

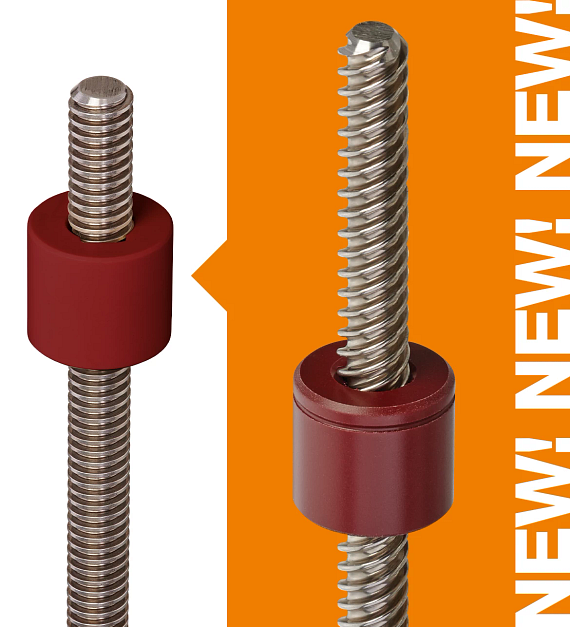

Of course, we have expanded our high-helix thread product range not only with the new lead screws, but also with the matching lead screw nuts.

► Different materials and types

► Lubrication-free and maintenance-free operation, low coefficients of friction and high efficiency

► Up to 50.9% lower acquisition costs compared to metal lead screw nuts

Check out the lead screw nuts from the dryspin lead screw technology for yourself. We have summarised all the advantages and important information for you at a glance.

► Different materials and types

► Lubrication-free and maintenance-free operation, low coefficients of friction and high efficiency

► Up to 50.9% lower acquisition costs compared to metal lead screw nuts

Check out the lead screw nuts from the dryspin lead screw technology for yourself. We have summarised all the advantages and important information for you at a glance.

Discover the matching lead screw nuts here

The alternative to conventional trapezoidal lead screws

More operating smoothness and less vibrations

The new high helix thread sizes DS10x3 LH, DS14x4, and DS18x4 are perfectly suited as an alternative to the trapezoidal lead screws of the same dimensions.

The dryspin high-helix lead screws offer numerous advantages:

► Quiet and low-vibration operation thanks to rounded teeth

► Longer service life due to asymmetry

► Higher efficiencies through optimised flank angles

► 100% corrosion-free, self-locking and many other advantages

The dryspin high-helix lead screws offer numerous advantages:

► Quiet and low-vibration operation thanks to rounded teeth

► Longer service life due to asymmetry

► Higher efficiencies through optimised flank angles

► 100% corrosion-free, self-locking and many other advantages

Get more information on the alternative to trapezoidal threads

dryspin® thread geometry

Smooth operation, less vibration - THE alternative to trapezoidal threads

What does lead screw technology mean and what do i understand by it?Lead screw technology is a part of drive technology and, roughly speaking, describes the repetitive conversion of a rotary movement into a translatory movement within regular cycles. The dryspin® lead screw technology patented in 2014 by the dryspin® lead screw technology development team. Particular emphasis was placed on increasing service life and improving efficiency. The dryspin® product portfolio includes high-helix lead screws made of stainless steel or aluminium and the matching lead screw nuts made of igus® high-performance polymers. They are available from 1mm to 100mm pitch. The dryspin® thread geometry is an extension of conventional thread technologies such as metric and trapezoidal threads. In contrast to conventional thread geometries, the dryspin® lead screw technology is superior with numerous advantages

Let's take a closer look at these:

In contrast to a metric or trapezoidal thread, the high helix thread has a higher pitch. Thus, a significantly increased linear feed is carried out with one revolution of the lead screw. dryspin® offers better efficiency thanks to the specifications and geometries tailored to the plastic nut and lead screw. Efficiencies of up to 82% and a longer service life are achieved compared to metal lead screw drives. In combination with an igus® lead screw nut, clean and dry operation is possible, without dust and dirt getting stuck.

We tested it!

Our dryspin® lead screw geometry is an excellent alternative to conventional trapezoidal threads. The specifications and geometries of our dryspin® lead screw technology, which are tailored to the iglidur® plastic nut and lead screw, guarantee the well-known advantages: tighter manufacturing tolerances, rounded teeth geometry, optimised flank angle and the asymmetry ideal for plastic nuts compared to DIN 103. Our dimensions are suitable for 1:1 replacement: DS10x2, DS10x3, DS12x3, DS14x4 and DS18x4.

Tighter manufacturing tolerances - improvement by a factor of 3

Trapezoidal threads according to DIN103 (TR18x4) are tolerated with up to -0.3mm on the outside diameter. Excessive radial clearance can lead to noise and vibration. Our dryspin® technology guarantees a maximum tolerance of -0.1mm with the same diameter and identical pitch. We improve the outer diameter tolerance by a factor of three and thus optimise smooth operation and precision, especially at high speeds.

Quiet and vibration-free operation and higher speeds thanks to the rounded tooth flanks of the dryspin® thread geometry

Due to the rounded tooth flanks and tighter manufacturing tolerances of the dryspin® thread geometry, the possible noise-causing contact surface between the lead screw nut and the lead screw is reduced. This is due to the fact that the greater the contact of two surfaces moving against one another, the more vibrations are transmitted, which can be perceived as a rattle or squeak. This means that higher travel speeds can be achieved without causing the corresponding noise.

Up to 30% longer service life - due to thread asymmetry

Due to larger gaps between the individual dryspin® thread pitches, the thread ideally adapts to the specifications of the lubrication-free igus® high-performance polymers. The proportion of the tribologically optimised polymer in the thread turns can be enhanced by a factor of 1.3. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to 5 times longer compared to standard thread geometries.

Go to test reports

Try out dryspin® technology for yourself

With the help of the free lead screw sample

Holding a real sample in your hands is an important part of understanding your component. We will be happy to send you a sample of our dryspin lead screw drives for this purpose. We have summarised all the specifications and advantages of dryspin lead screw technology in the sample for you. See for yourself and if you have any questions, our experts will be very happy to help.Request free lead screw sample here