3D printing with several filaments

What is multi-material printing?

Multi-material printing uses two different filaments to make one component in a single work step. This combines the advantages of two or more different materials in one component.

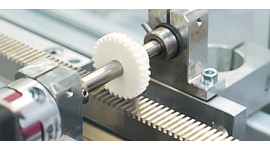

The filament that igus developed specifically for mechanical engineering is called the "tribofilament". Filaments under this name have outstanding, unique wear resistance properties and very good coefficients of friction. But other filaments have also been specially optimised for strength and rigidity. Multi-material printing can combine tribofilaments with other materials within a component so as to supplement the high wear-resistance with other mechanical and functional properties.

The filament that igus developed specifically for mechanical engineering is called the "tribofilament". Filaments under this name have outstanding, unique wear resistance properties and very good coefficients of friction. But other filaments have also been specially optimised for strength and rigidity. Multi-material printing can combine tribofilaments with other materials within a component so as to supplement the high wear-resistance with other mechanical and functional properties.

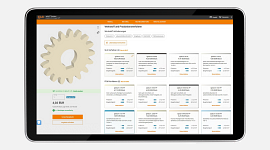

Shop your design

What kinds of multi-material combinations are there?

How and with what materials can iglidur® tribofilaments be combined?

Many materials are compatible and can be combined in one way or another in two-component printing. Similar filaments (such a materials with the same base polymer or similar processing temperatures) can be firmly bonded: the materials meld with one another, connecting the component's two "phases". This no longer functions when the difference between processing temperatures is too great: then one of the two materials may not remain dimensionally stable during processing or may even be subjected to damaging temperatures. To be absolutely certain of the connection, an interlocking design in which the two phases are combined so that they cannot be separated by non-destructive means is a good option.Mechanical properties

Injection moulding with 3D printing

This make it possible to implement geometries that are only possible with 3D printing in combination with the larger choice of available materials in the area of injection moulding. All iglidur® materials are offered which opens lots more doors to the applications. Find out more about iglidur® materials.

3D printing with smart functions

Find out more about 3D isense

Multi-material 3D printing with up to four materials

Rapid production of multi-functional special parts in a single work step

A four-component printer allows tribofilaments to be combined with up to three other filaments. This gives rise to multi-functional special parts that are 3D printed and thus manufactured quickly and economically in a single work step.

One possible combination is intelligent bearings for predictive maintenance: a fibre-reinforced housing, tribofilament at stress points, and integrated sensors to warn of bearing overload.

Other application areas include abrasion-resistant components with integrated seals.

One possible combination is intelligent bearings for predictive maintenance: a fibre-reinforced housing, tribofilament at stress points, and integrated sensors to warn of bearing overload.

Other application areas include abrasion-resistant components with integrated seals.

Where are two-component parts used?

Deflection lever

A component for deflecting forces; its great rigidity protects the joint from interfering influences.

The bearing points operate especially smoothly and are durable and wear-resistant.

A good solution here is a combination of a carbon-fibre-reinforced filament such as igumid P150 and a tribologically optimised material such as one of the igus® iglidur® tribofilaments.

The bearing points operate especially smoothly and are durable and wear-resistant.

A good solution here is a combination of a carbon-fibre-reinforced filament such as igumid P150 and a tribologically optimised material such as one of the igus® iglidur® tribofilaments.

Gripper

The dynamic requirements dictate that the gripper element be as light as possible, but with great flexural strength, and grip securely but gently. While the gripper's body is manufactured with a fibre-reinforced filament, a flexible filament whose high coefficient of friction ensures a secure grip can be used for the gripping surfaces.

Customer application: two-component gripper in the packaging industry for cosmetics products

Other wear tests

3D printing with iglidur compared to PLA, ABS and other materials and manufacturing processes3D printing news

Discover more innovations in the field of additive manufacturing at igus, and find our everything about our new materials and services.Our innovations at a glance

More information about igus® 3D printing

News

Discover our new products and service tools for additive manufacturing!

Go to the innovations!

Tested!

3D printing materials made of iglidur compared to PLA, ABS and other materials and manufacturing processes.3D printing service

Customised, additively manufactured components with the online 3D printing service in just a few steps.To the igus® 3D printing service

Industry brochure

Receive information about all solutions that igus® offers for additive manufacturing.Download a free brochure