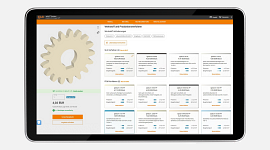

Intelligent 3D-printed wear-resistant parts

Integrated sensors measure component service life and issue a warning if there is an overload

The engineers in the igus 3D printing team have now achieved a further great step: sensors are incorporated in the tribo-component via multi-material printing. Long before failure, it signals that a replacement is imminent. It can also detect overload in order to stop the application immediately and prevent further damage to the bearing position and the entire system. This enables predictive maintenance for special parts as well, with the result that machine downtime and maintenance work can be reduced. Due to additive manufacturing, such intelligent 3D isense components can now be delivered in a cost-effective way from five business days.3D isense is suitable for the manufacture of intelligent plain bearings, sliding elements, lead screw nuts and all other special parts that are susceptible to friction and wear.

Send a project request

3D printing i.Sense – intelligent and wear-resistant

Tech up

- Wear-resistant parts with sensors via multi-material 3D printing

- Warning when the wear limit is reached

- Warning before overload occurs ► Avoid damage

- Predictable service life

Cost down

- No minimum order quantity, no tool costs

- Ready to ship in only 3 working days or more (upon request)

- No unplanned downtime

- Reduce failure costs

Proof

- Tested in the igus test laboratory

- Try it out in your own application in order to see for yourself; igus is offering free samples of 3D isense components in the beta test phase.

Sustainability

- No lubrication necessary

- 3D printing: less material needed as there is no

waste or sprue - igus supports the circular economy of

plastics and is investing in chemical recycling.

Learn more about the topic of plastic2oil here.

Development

igus has been developing intelligent wear-resistant parts since 2016, and is by now using them in energy chains, plain bearings and linear guides. When designing these wear sensors, our developers have been using the igus 3D printing service for wear-resistant parts.That way, special gliders have been manufactured via laser sintering and made of iglidur I3; the intelligence was incorporated afterwards in a second process step.

This has lead to the intelligent special parts being very complex and cost-intensive when produced in small numbers, as the downstream work steps are very specific and tailored to the individual component. The 3D printing developers accepted this challenge and came up with a procedure for producing such intelligent wear-resistant parts in one work step via 3D printing. Now, as no further processing steps are necessary, intelligent special wear-resistant parts can be manufactured cost-efficiently from five working days on.

Function explained

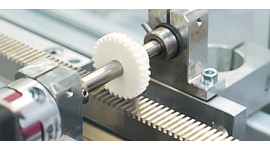

During printing, the sensor layer is applied to those parts of the component that will be subjected to load. When in use, the electrical resistance of the sensor material is measured continually so that a warning is issued before overloading or before the wear limit is reached.Based on the procedure for multi-material printing, wear-resistant parts with integrated sensor layers are developed. The components are made from the wear-resistant filaments iglidur I150 or iglidur I180 and a specifically developed electrically conductive 3D printing material that sticks well to the tribofilament.

Currently, there are two application areas:

► Warning before overload occurs: The electrically conductive material is situated between the wearing layers. If the load changes, the resistance also changes. To determine the load limits, the bearing has to be calibrated correspondingly.

► Reaching of the wear limit: the conducting path is located in the gliding surface, the wear is measured via the der change of the resistance.

Become a beta tester and try 3D isense for free: we are offering ten selected customers the opportunity of free samples with intelligent special parts.

Further smart plastics® solutions in the igus range of products

smart plastics solutions for condition monitoring and predictive maintenance

The term "smart plastics" is used to refer to components such as e-chain systems, chainflex cables for dynamic applications, and drytech plastic bearings that – equipped with connectivity and sensors – locally network complex automation solutions or enable Industry 4.0.

Smart maintenance for igus energy supply systems ... with smart plastics

Integrated service life monitoring for energy chains and cables

Predictive maintenance or crash avoidance on energy chains with smart plastics from igus. The sensor technology allows for the measurement of pin/bore connection abrasion in percentages and, by precisely determining the product's service life, helps reduce costs while preventing premature e-chain system® replacement.

Sensors for smart energy chains

isense plain bearings from the catalogue product range

The isense plain bearings signal their wear status in good time before the machine can be damaged because of bearing failure. Available in five special materials, the intelligent plain bearings can be used in a wide variety of industries and applications.

Learn more about isense plain bearings from the catalogue product range

isense linear carriages with LED display

The function and wear test for the drylin isense linear carriage can be carried out at the push of a button. Thanks to the innovative drylin W technology, the linear bearing can be replaced directly on the rail in just a few seconds - LEDs on the linear carriage indicate when replacement is due. The wear sensor is integrated directly into the linear liner.

LED carriages

Why 3D printing at igus?

Our additive manufacturing is based on five decades of expertise in the industrial production of wear-resistant components made of self-lubricating high-performance polymers for innumerable customers all over the world. With the specially developed compounds for 3D printing, it is now possible to manufacture prototypes, special parts and small volumes quickly and without tool costs. iglidur filaments and SLS powder are many times more wear-resistant than regular 3D printing materials - they are on the same level as iglidur plain bearings made with the injection moulding method. This illustrates their suitability for industrial use as long-lasting function-performing parts.In addition to diversely usable materials with tribological properties, we supply special solutions with FDA compliance, ESD protection and fire retardance as well as advanced manufacturing technologies, such as multi-material printing and 3D printing with incorporated sensors for predictive maintenance. Our materials can be purchased in the online shop for further independent processing or ordered through our online 3D printing service with just a few clicks of the mouse by means of a STEP file. The goods are usually delivered within one to three days.

The iglidur 3D printing polymers are thoroughly tested in the in-house test lab with regard to wear and friction. That way, the service life of igus 3D printing components, e.g. as gears or plain bearings, can be calculated online in advance. In addition to special polymers, we provide a specialist consultation service, useful online tools and configurators, learning and further training material as well as free samples of our materials and the components made from them.

Further information on 3D printing with wear-resistant polymers

More information about igus® 3D printing

News

Discover our new products and service tools for additive manufacturing!

Go to the innovations!

Tested!

3D printing materials made of iglidur compared to PLA, ABS and other materials and manufacturing processes.3D printing service

Customised, additively manufactured components with the online 3D printing service in just a few steps.To the igus® 3D printing service

Industry brochure

Receive information about all solutions that igus® offers for additive manufacturing.Download a free brochure