Improve your technology & reduce costs now with drylin® linear technology

Determine your personal savings potential NOW*

*Whether we are talking about savings in terms of time or money spent on installation, selection, design etc., or about technical improvement in the form of ease of installation, durability etc., if we are unable to show you any savings or technical improvement, we will recommend an alternative solution.

*Whether we are talking about savings in terms of time or money spent on installation, selection, design etc., or about technical improvement in the form of ease of installation, durability etc., if we are unable to show you any savings or technical improvement, we will recommend an alternative solution.

Cost down

- Cost-effective production in injection moulding

- Save time with fast assembly (just seconds)

- No lubricants necessary

Always the most cost-effective linear guide that works.

With drylin linear technology from igus.

Overengineering is a thing of the past. The best linear guide does not have to be the most expensive one.

Very quickly find the linear guide with the best price/performance ratio for your application.

Calculate service life quickly and easily online

Take just a few minutes to find out how long our linear technology will last in your application - and then choose the linear technology with the best price/performance ratio. Individually designed for your application.Calculate the service life now

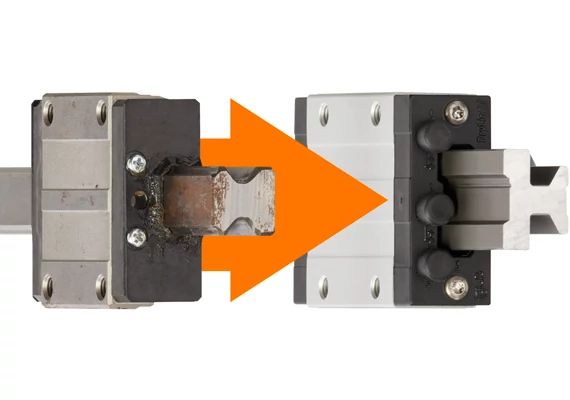

▲ Tech up

Do without lubricants completely

For linear technology made of metal, lubrication is indispensable as otherwise it could rust, seize or become severely worn. With our linear technology, which relies on plastic for moving parts, you do not need even a single drop of lubricant. That way, you can benefit from complete freedom from maintenance, high resistance to dirt and significant hygienic standards.

Save up to 50% weight

Linear technology made of metal is very heavy. But drylin linear technology is very lightweight as it is made of plastic and aluminium, making it a better alternative for many applications. Plastic linear technology is often used in the automotive industry and aerospace engineering. Wherever low weight is important, our lightweight plastic linear technology is a good solution.

▼ Cost down

Up to 50% more cost-effective than comparable metal solutions

Plastic linear technology stands out from its metal counterpart not only due totechnical advantages,such as freedom from lubrication and corrosion, but also because it is up to 50% more cost-effective.

Buy cost-effective linear technology here – in our online shop

Do you need further price comparisons for your linear technology made of metal, plastic or ceramic in order to identify your savings potential? We advise you! It's our job!

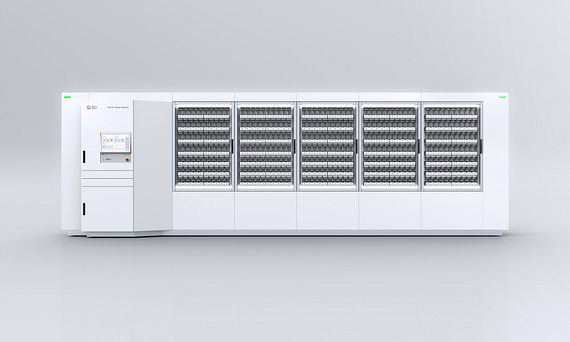

∎ Smooth operation decisive

A long service life in 24/7 operation was the requirement for a circulation system for this automated blister packaging centre. Several hundred patients, who spend seven days in hospital on average, have to be given the correct medicines 24/7, which are packaged individually here.

drylin W profile guides | High helix thread with plastic nut | drylin W linear bearings

Further customer references

KHS Labelling machine | Fabmaker | Motion Solutions GmbH

● Sustainability

For our linear technology, you need not a single drop of lubricant. Not only our users, but also the environment profit from this. Furthermore, tribologically optimised plastics show a significantly improved abrasion behaviour when compared to conventional plastics .

Tech up. Cost down. Change now!