All questions and answers about dryspin lead screw technology

General

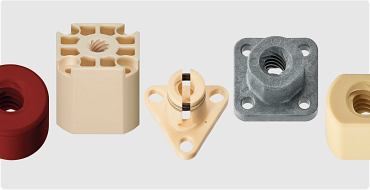

It offers a wide range of different lead screw nuts and lead screw models in various dimensions. The range of dryspin® high helix threads includes diameters from 4 to 20mm and pitches from 2.4 to 100mm. Due to the diversity of the product range, the dryspin thread geometry is conceivable in almost all applications.

Basically, yes. It is necessary to adhere to the application parameters (axial load, rotation speed, etc.) and reach the required positioning accuracy. Our lead screw drive expert offers optimal help for choosing the perfect lead screw system for every application.

► Higher efficiencies

► Quiet and low-vibration operation

► 30% longer service life due to asymmetry

► Up to 25% less wear

► Higher efficiency

Our drylin lead screw nuts are up to 50.9% more cost-effective than metal lead screw nuts. Also up to 69% more cost-effective compared to comparable plastic lead screw nuts and up to 50% more cost-effective compared to ball screw systems.

Self-locking means that lead screw nuts and lead screws cannot be moved without the application of external force. It has to do with the pitch and coefficient of friction.

Lead screw nuts that are made of tribologically optimised iglidur® materials can be used in temperature ranges between -20°C and +150°C.

Our lead screw support blocks are available in thread sizes of 6-24mm. Choice of mounting: plain bearings or, with higher dynamics, ball bearings (BB). All lead screw support blocks, like the matching lead screw clamp rings, are supplied in hard anodised aluminium.

In addition to the correct choice of material for the lead screw nut, a preload mechanism against unwanted bearing clearance has proven to be an effective measure in practice. For trapezoidal threads and dryspin® high helix threads, anti backlash, zero backlash & low clearance versions with preload of the thread nut are available.

It is no secret that igus is an advocate of non-lubrication of bearings. Simply put, lubrication is not required for igus products. We often hear from customers the recurring question: “Can I use WD-40 or another lubricant to lubricate my bearing? ”

Lead screw nuts

The special type of the JGRM threaded nut, in combination with a stainless steel plate, allows the accommodation of static loads of up to 6 MPa.

The most important thing to remember when installing a polymer flange lead screw nut is not to exceed the maximum tightening torque of 2.5Nm. It is also recommended to secure the fastening screws with a third medium, e.g. a semi permanent thread locking glue.

When installing a cylindrical lead screw nut made of polymeric, axial and radial locking is necessary. An option for radial locking is the use of set screws. Axial fastening through a sheet metal ring possible.

In addition to the correct choice of material, a preloading mechanism has proven to be an effective measure to reduce unwanted axial clearance. For our dryspin® high helix threads and trapezoidal threads there are three versions with preload: Zero-Backlash, Low-Clearance and AB lead screw nut. Here you will find all the advantages and assembly instructions for our clearance-reduced lead screw nuts.

Lead screws

► What is the difference between single and multi-start threads?

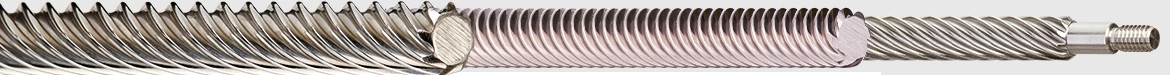

Single-start lead screws consist of only one thread. This means that the distance between the flanks, marked by pitch, is also the linear travel (lead) in millimetres per revolution of the lead screw.

If another thread is added, the lead screw reaches twice the stroke (2x pitch) with one revolution. The calculation for the linear travel always remains the same depending on the number of threads, only the pitch of a single thread differs. This procedure can also be applied to our multi-start dryspin® high helix lead screws.

At igus, we distinguish between two manufacturing processes: thread rolling and thread whirling. Both processes have their special specifications. The company igus uses thread rolling as a standard process because of the cost savings, better surface finish and longer service life. Thread whirling is more suitable for small quantities and for very precise threads with narrow tolerances.

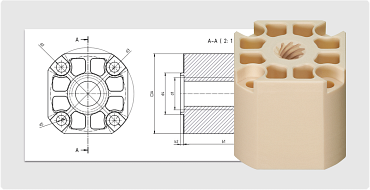

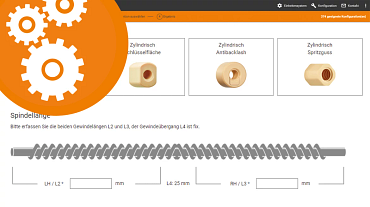

From the idea to the finished lead screw in just five minutes. The configurator enables engineers to quickly find the right lead screw and machine the ends from both sides. The application generates a dimensioned drawing of the configuration for you.

Materials

Our lead screw nuts are available in 6 different materials: iglidur® J, iglidur® 350, iglidur® R, iglidur® A180, iglidur® J200, iglidur® E7 and iglidur® W300. The differences and advantages of the individual materials can be found here:

| Material | MPa |

|---|---|

| iglidur® J | 4 MPa |

| iglidur® W300 | 5MPa |

| iglidur® A180 | 3.5 MPa |

| iglidur® J350 | 2 MPa |

| iglidur® E7 | 0.5 MPa |

| iglidur® J200 | 2 MPa |

| iglidur® R | 2 MPa |

Tolerances

Apart from the pitch accuracy of 0.1 to 300mm, customer-specific tolerances are implemented in the end machining of the lead screws and the machining of nuts.

According to DIN 103, tolerance class 7e

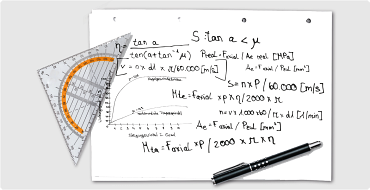

Calculation formulas

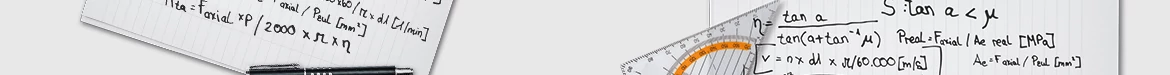

Ae = Faxial / ppermitted [mm2]

pv = preal x v

v = nxd1xπ/60,000[m/s]

n = vx1,000x60/πxd1 [1/min]

s=nxP/60,000[m/s]

Mta= Faxial x p/2000 x π x η

Mte= Faxial x p x η/2000 x π

The load capacity of trapezoidal lead screw nuts made of high-performance polymers depends on the surface pressure, the sliding speed and the resulting temperature. The temperature behaviour is also influenced by the operating time and the selected lead screw material and its specific thermal conductivity.

Surface speeds of the iglidur® materials in m/s:

| iglidur® material | Rotating long-term |

|---|---|

| iglidur® J | 1,5 |

| iglidur® W300 | 1,0 |

| iglidur® A180 | 0,8 |

| iglidur® J350 | 1,3 |

With the pv value and the percentage contact area stated in the dimensions tables, the permissible sliding speed and from it the feed speed for each thread size can be determined.

Standard values when using drylin® polymer nuts without lubrication (with 500mm stroke). A correction factor must be reckoned for very short or long strokes.

| Operating time ED | pv-valuemax.[MPaxm/s] |

|---|---|

| 100 % | 0,08 |

| 50 % | 0,2 |

| 10 % | 0,4 |

| Faxial | Axial force |

| Ppermitted | Max. permitted surface pressure 5N/mm2 |

| preal | Actually occurring surface pressure for the selected size |

| Ae real | Effective support surface of the selected trapezoidal lead screw nut |

| P | Pitch |

| d1 | Pitch diameter |

| Mta | Drive torque [Nm] when converting a rotation - into a longitudinal movement |

| Mte | Drive torque [Nm] when converting a longitudinal movement into a rotary movement |

| v | Surface speed [m/s] |

| Øs | Feed rate [m/s] |

| n | Speed [min-1] |

| η | Efficiency |

preal = Faxial / Ae real [MPa]