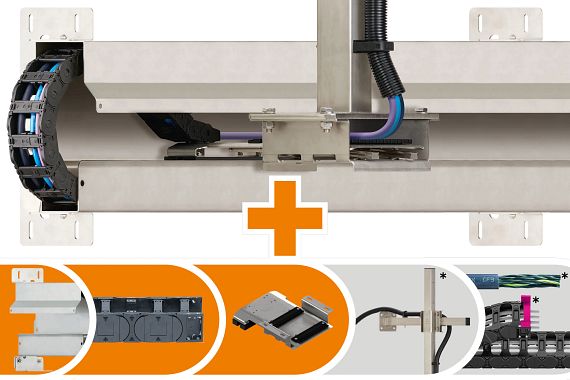

Basic flizz® enclosed guide system

The basic flizz® at a glance

We have summarised five important features of the basic flizz system for you here:

1. Safe guidance: glide bar integrated in the profile.

2. Modular design: easy assembly, compact construction

3. Protected: weather-resistant stainless steel enclosure

4. Fast assembly: openable along the outer radius

5. Wide range of installation options

Typical industries and applications:

Wastewater treatment plants, longitudinal scrapers, grit chambers, grease traps, wastewater treatment, electroplating plants, cranes, plant engineering, sluices

Visit the shop

Advantages of the system

- Low-maintenance system for travels up to 100m

- Protection against weather and dirt exposure

- Cost-effective and fully enclosed complete system

- Standardised, modular design

- Easy installation using a bracket with different mounting options

- Cable lengths up to 50% shorter than festooning, lower clearance height and no loop station

- At all times, cables are guided with a defined bend radius whereby the tensile forces are absorbed by the e-chain

- Cables cannot tangle or become damaged

- No slip ring contact (as with cable reels, for example)

- Cables or hoses can be easily retrofitted as required

- Reduce power costs - directly driven by the scraper, no additional drives needed (e.g. (as with cable reels, for example)

- moving end arm optionally available (e.g. as mechanical connection for scraper trolley)

- Available in two sizes, each can also be delivered in HD version for even higher push/pull forces

- 3500 v2 and 3500 HD optionally available as rol e-chain® for travels up to 200m and more

Adjustable moving end arm

In addition to the floating moving end of the basic flizz® 2500 v2 and 2500 HD, igus® offers a modular and adjustable moving end arm for easy installation onto the existing structure.

Dimensions: approx. 700mm wide, 1,000mm high, square tube 60 x 60mm

Material: stainless steel AISI 304 (304 stainless steel/204)

basic flizz® system

Complete sets in the shop

The basic flizz is a system for mobile energy supply to scrapers, rakes and other sewage treatment and hydropower plants.A complete set consists of an energy chain that is filled with the tested chainflex® cables and guided safely in a weatherproof stainless steel housing.

With the developed driver arm and the smart plastics system EC.P for push/pull force detection, this set is a very good complete solution.

Visit the shop

basic flizz in use

Sewage treatment without downtime in the Plauen sewage plant

The basic flizz system reliably guides cables along the side of the primary clarifier over a distance of 53 metres. The energy chain in the housing is suitable for long travels and ensures a long service life of the cables. They are guided with a defined bend radius and the energy chain absorbs developing tensile forces. That way, cable-related downtime is avoided.Further application examples

Primary clarifier in Plauen

In the large sewage treatment plant in Plauen, our basic flizz system reliably supplies the scraper bridge with energy. It replaces a motor cable drum, and since then the energy and signal supply of the primary clarifier has been running smoothly. The new system - a ready-to-install combination of energy chain and stainless steel enclosure - was specially developed to meet the requirement profile of sewage treatment plant operations.

To the application example

Sand trap basin of the Bamberg sewage treatment plant

Increasing process reliability, minimising maintenance effort, transmitting data in a sustainable manner - these are the requirements for the energy supply of the sand trap scraper in the sewage treatment plant in Bamberg. A reliable energy chain system from igus ensures the necessary functional safety.

To the application example

Primary clarifier at the Plauen ZWAV sewage treatment plant

In the Plauen sewage treatment plant, the Zweckverband Wasser und Abwasser Vogtland (ZWAV) has replaced the motor cable drum that used to supply a scraper with energy with the "basic flizz" system from igus. Since then, the energy and signal supply of the primary clarifier has been running smoothly.

To the application example

Intelligent technology for every wastewater treatment plant

Sewage plants pose a challenge for the components in use: they are in continuous operation, exposed to all sorts of weather conditions and come into contact with fluids, grease and dirt.

Our intelligent energy chain systems are designed to operate fail-safe under all conceivable conditions for as long as possible.

Find out more

24/7 condition monitoring in the sewage treatment plant

Sewage treatment plants run 24/7, 365 days a year. The use of a basic flizz system is very suitable for most rectangular clarifiers. The advantage of the system is the modular design and the protection of the energy supply system against wind and weather. The flizz system can be installed either directly on the tank wall or on the floor along the tank.Additional protection is provided by the smart plastics i.Sense EC.P system (EC = e-chain P = pull force) for intelligent condition monitoring of the chain. This allows the system to switch off proactively and automatically in the event of a malfunction in order to avoid a total failure.

To the application example

Installation service

Save time and money on the maintenance and installation of your energy chain systems

We have the expertise when the job calls for reliable energy supply systems and their installation at the customer's site, ranging from individual energy chain link replacement to major modernisation projects, from individual component assembly to fully harnessed systems.This experience also allows us to give a system guarantee of up to 36 months or more on energy supply systems installed by igus* – after all, we know our products and services.