Sewage plants: reliable hazard prevention and smart condition monitoring in one

Optimum guarantee of plant availability ... at any time and from anywhere ... with igus i.Sense

Sewage treatment plants pose a challenge for the components in use: they are in continuous operation, exposed to all sorts of weather conditions and come into contact with fluids, grease and dirt. Our intelligent energy chain systems are designed to operate fail-safe under all conceivable conditions for as long as possible.

Whether in the longitudinal scraper on the primary clarifiers or on the grit and grease trap: with the ready-to-install IIoT solutions from smart plastics you avoid downtimes, reduce operating costs and cut down costly maintenance. Especially for wastewater treatment, we offer individual modules for reliable condition monitoring or Industry 4.0-capable complete packages for predictive maintenance concepts.

Whether in the longitudinal scraper on the primary clarifiers or on the grit and grease trap: with the ready-to-install IIoT solutions from smart plastics you avoid downtimes, reduce operating costs and cut down costly maintenance. Especially for wastewater treatment, we offer individual modules for reliable condition monitoring or Industry 4.0-capable complete packages for predictive maintenance concepts.

Make an appointment for introduction incl. a virtual tour

"What should I consider with respect to maintenance when selecting e-chains®?"

10 tips for a "maintenance-friendly" energy chain

What this means in concrete terms and what designers should bear in mind - this small guidebook will provide you with numerous practical tips and tricks.

For free PDF download

Different challenges in wastewater operations ...

... Always the right solution at hand with smart plastics

Push/pull force monitoring

Nowadays, modern wastewater treatment plants often run around the clock and without any control authority, which is why malfunctions sometimes remain undetected for hours. Although the plant runs at a very slow speed, in the event of a failure it can lead to a total breakdown.This is exactly where our i.Sense EC.P is used. This sensor continuously measures the force which the plant requires to move the energy supply system. If these forces change due to external influences such as ice, an animal or a tool forgotten during maintenance, the sensor detects this change and switches the system off immediately. This prevents expensive total damage to the sewage treatment plant.

Learn more

Chain breakage detection

Increasing process reliability, minimising maintenance effort, transmitting data in a sustainable manner - these are the requirements for the energy supply of the sand trap scraper in sewage treatment plants. The intelligent breakage detection i.Sense EC.B by smart plastics ensures the necessary functional reliability.The EC.B sensor immediately detects a chain link breakage and triggers a message if one occurs. This is implemented by a cable tensioned by the e-chain, which records every change in length and reports it to the EC.B sensor. This allows you or your system to intervene, frequently preventing both additional damage (to the opposite chain link) and system shutdown.

Learn more

Remote dashboard

Most wastewater treatment plants can now do without human monitoring personnel. However, the increasingly modern wastewater companies not only need an absolutely reliable cable guidance system, but also the possibility of being able to report the current operating status from anywhere and at any time.This is optimally solved with the new i.Cee Dashboard, which can be integrated online on the Internet or on-site in the local network. This means that the current operating data can be accessed either via a display on the crane, via a cloud solution or an IoT dashboard, via the REST API interface or even directly via SMS or e-mail.

Learn more

Condition monitoring | i.Sense

Condition monitoring is the easiest and quickest way to turn many igus products into self-monitoring, smart plastics products. Sensors are mounted to measure values, such as temperature, forces and vibrations within pre-defined limits. Values outside the limits result in an alert or a notification. Based on this information, a decision can be made about the next steps, maintenance or shutdown. At igus, we summarise the condition monitoring under the term i.Sense ("I feel").Go to condition monitoring

Predictive maintenance | i.Cee

In contrast, predictive maintenance solutions use sensors and software to create a system that enables dynamic service life calculation and optimal maintenance times. Predictive maintenance is the next step towards the implementation of a comprehensive smart Industry 4.0 system. The goal is always to maximise system and user safety as well as product life. We at igus call our predictive maintenance system i.Cee (derived from "I see ahead").Go to predictive maintenance

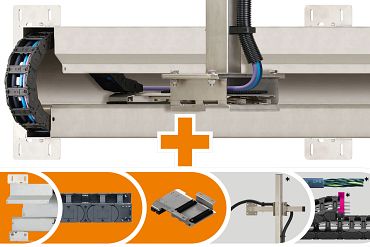

basic flizz®: the enclosed energy supply

The basic flizz® is a complete system for mobile energy supply to scrapers, rakes and other sewage treatment and hydroelectric power plants. It consists of an energy chain filled with chainflex cables, guided safely in a weatherproof stainless steel enclosure.

- Safe guidance: guide rail integrated into the profile

- Modular design: easy assembly, compact construction

- Protected: weather-resistant stainless steel enclosure

- Fast assembly: openable along the outer radius

- Wide range of installation options

Basic flizz® overview

Smart basic flizz® system at the click of a mouse

Order ready-to-install complete sets directly in the online shop

The basic flizz is a system for mobile energy supply to scrapers, rakes and other sewage treatment and water power plants. A complete set consists of an energy chain filled with tested chainflex cables and guided safely in a weatherproof stainless steel housing. With the developed driver arm and the smart plastics system EC.P for push/pull force detection, this set is a very good complete solution.Go to shop for complete sets

24/7 condition monitoring in the sewage treatment plant

Sewage treatment plants run 24/7, 365 days a year. The use of a basic flizz system is very suitable for most rectangular clarifiers. The advantage of the system is the modular design and the protection of the energy supply system against wind and weather. The flizz system can be installed either directly on the tank wall or on the floor along the tank.Additional protection is provided by the smart plastics i.Sense EC.P system (EC = e-chain P = pull force) for intelligent condition monitoring of the chain. This allows the system to switch off proactively and automatically in the event of a malfunction in order to avoid a total failure.

More on the wastewater treatment plant user report

White paper: energy chains vs. motor cable drums

Advantages and disadvantages of both systems

Whenever designers have to guide hoses as well as cables in moving applications with long travels of more than 100 metres, the question arises: which energy supply system is the most efficient? A motor cable drum? Or an energy chain? The advantages and disadvantages of both systems.Download white paper now

You determine the manner of data transfer and access

Data transfer within your local corporate network (i.Cee:local) or on a secure cloud (i.Cee:cloud)

i.Cee:local

i.Cee:cloud

smart plastics selection guide

Choose for yourself which smart solution suits you best

With just a little information about your application, the online consultant guides you in a targeted manner to a pre-selection of smart plastics solutions. During the selection process, the tool provides an overview of the current smart plastics options.

Start the selection guide now