Continuous panel feed e-spool® flex 2.0

The e-spool flex 2.0 is the igus version of a cable drum without a slip ring. Cable diameters from 5mm to 15mm can be used. The cable is always safely routed through a feed-through to ensure that it is wound up correctly.

Chat with our e-spool® expert Patrick Johnston directly on Teams!

Contents:

Chat with our e-spool® expert Patrick Johnston directly on Teams!

Contents:

Visit the shop

Tech up

- Without interruption (no slip ring) also for energy,

data, fluids and air - Space-saving

- Can be fitted universally

- Constant tensile strain on the cable

- Locking mechanism of the cable

Cost down

- Cost-effective

- Easy in case of repair

- Simple replacement of the fitted cable, therefore adaptable

- Four configuration levels adapted to your requirement

Proof

- Tested in the igus laboratory: e-spool flex pull-out forces and e-spool flex mini extension length compared to the competitor product

Sustainability

- No additional copper components in the system (apart from cable copper)

- Parts are reusable

- Less raw material required thanks to the option of partial repair instead of complete replacement

- Have your energy chain recycled at the end of its life cycle with the igus Chainge recycling program . Irrespective of the manufacturer. You will receive a voucher for: chainge recycling program

- igus has been an investor in Mura Technology from the beginning and is helping advance chemical recycling. From plastic waste to crude oil in 20 minutes.

Installation instructions

The illustrated assembly aid enables you to assemble the e-spool flex 2.0 and e-spool flex mini quickly and professionally.Drive options e-spool flex

Cable diameter: from 5 to 15mm

Extension length: ≤15m

Visit the shop

Cable diameter: from 5 to 15mm | Extension length: ≤15m

Visit the shop

Drive options e-spool flex mini

Cable diameter: from 5 to 7mm

Extension length: ≤3m

Visit the shop

Cable diameter: from 5 to 7mm

Extension length: ≤3m

Visit the shop

Note: Please consider VDE 0298 Part 5 (Current carrying capacity and conversion factors for wound cables) when selecting your cables and when using e-spool flex

NEW: e-spool flex accessories

Now with guide roller and brush attachment (optional)Brush unit

Brush attachment for cleaning the cable before rolling it up.Guide roller

Idler pulley for "around the corner" extension.Documentation

Documentation cable drum e-spool flex

This documentation will provide you with all important information about e-spool flex - from technical data to hazard warnings to safety instructions.Download now

Documentation cable drum e-spool flex mini

This documentation will provide you with all important information about e-spool flex mini - from technical data to hazard warnings to safety instructions.Download now

White paper: slip ring-free cable reel with screw guide

With a newly developed cable reel for control panels, robot users avoid

"cable tangle" and tripping hazards in automated production. Since the new solution does not use slip rings, media, data and the power and signal supply of the emergency stop button can also be integrated into the system. Download the white paper to find out more.

"cable tangle" and tripping hazards in automated production. Since the new solution does not use slip rings, media, data and the power and signal supply of the emergency stop button can also be integrated into the system. Download the white paper to find out more.

Download white paper now

Structure of the e-spool flex 2.0

Discover the structure of the e-spool flex in the video.

Tested in the igus laboratory

For e-spool flex pull-out forces

The results showed that the e-spool pull-out forces were about ten newtons, while those of the competing product were almost twice that.

A: e-spool flex

B: Competing product

C: Pull-out force [N]D: Pull-out [m]

For the e-spool flex mini extension length

The results showed that the e-spool flex mini extension length was about three metres, while that of the competing product was only half that.

Related products

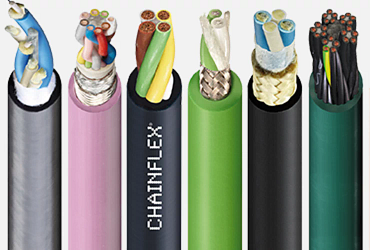

chainflex®

Find out more

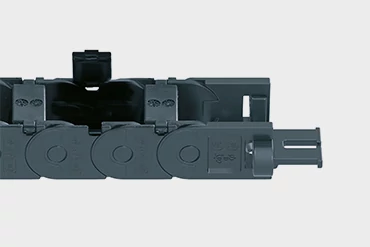

energy chains

Find out more

readychain®

Find out more

Possible uses for the e-spool flex 2.0

... on industrial robots

Possible uses for the e-spool flex 2.0

... in the car repair shop

Possible uses for the e-spool flex 2.0

... on platforms

Possible uses for the e-spool flex 2.0

... in harbours

Possible uses for the e-spool flex 2.0

.. in the warehouse

Possible uses of the e-spool flex mini

... at the dentist's

Possible uses of the e-spool flex mini

... at charging stations for e-bikes

Possible uses of the e-spool flex mini

... in the office