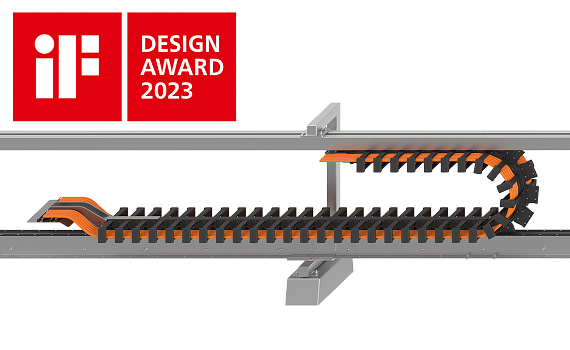

drive-chain

[Design study] drive-chain 2.0

Extreme dynamics and very long travel distances with a wear-free drive

The world's first energy chain system with its own drive, now almost wear-free with a linear motor. For very long travel distances (1,000m and more) with extreme dynamics and long operating times. For next-generation ASCs (automated stacking cranes). The lower mass allows higher acceleration and speed, and the drive-chain 2.0 also offers a much longer service life than do standard energy chain systems.Send a drive-chain query now

Tech up

- Virtually wear-free linear drive for even less friction over very long travel distances

- Drive force does not have to come from the powered system (e.g. crane), because the e-chain system has own drive

- Two drive concepts (linear drive & friction wheel drive)

- Significantly higher operation times because there is almost no stress caused push/pull force

- For ASC (Automated Stacking Cranes) next generation cranes

- Higher acceleration & speed possible due to lower mass

Cost down

- Significantly longer service life compared to standard energy chain systems

- Shorter cable lengths, due to central feed, resulting in lower cable costs when purchasing

Proof

- Test setup in the igus laboratory

Sustainability

- 4 - 6t less moving mass on the crane, thus less energy consumption

- igus® has been an investor in Mura Technology from the very beginning and is advancing chemical recycling. From plastic waste to crude oil in 20 minutes.

Before

After

Other systems for long travels

Discover products now

Energy chain systems for cranes

Further information

Free white paper

Triple E-class container ships and the requirements of energy supply for STS cranes

- The challenge: cranes for Triple E-class container ships

- Crane availability and dependability requirements

- Comparison of energy and signal supply systems (festoons, busbar systems and energy chains)

- Technological outlook: rol e-chains

Download white paper now

Successful application stories in the crane industry

Fifty percent more storage space

An exceptionally space-saving solution has been developed for the energy supply system of a fully automatic crane system, which has proven itself under the highest loads and in continuous operation - and which today creates 50 percent more storage space.Learn more about this application

Reliable despite continuous operation

A roller energy chain is in operation at one of the largest bulk handling ports in Western Europe. On the massive ship-to-shore crane, it operates without incident despite continuous operation and over 100 metres of travel.Learn more about this application

... and other success stories

Discover how our energy chains and chainflex cables are used in the crane industry for different requirements in this selection of application examples sorted by crane type.Discover further success stories

You might also be interested in

Energy chains shop

Buy energy chains now