Successful use in facade and building technology

Our products have already been tested thousands of times in practice and have proven themselves in numerous applications in facade and building technology. By switching from metallic to lubrication-free dry-tech bearing products, our customers have been able to improve the technology of their systems and bring costs down: with longer service life and less maintenance. In the following, you can find a selection of customer applications that have already been realised.

Maintenance-free and UV-resistant bearing technology in an innovative sun protection facade system

The French company Arcora has developed a sustainable, innovative sun protection system that doesn't require the usual motorisation. Our plain and spherical bearings as well as our linear guides are used in the interfaces between the moving and fixed elements.

More about the application

Maintenance-free plain bearings for 1,028 sun protection slats at the E.ON technical centre

To keep the workload as low as possible after installation of the exterior facade, the bearing technology needed at the vertical slat pivot points had to be as maintenance-free as possible. iglidur J plain bearings were chosen because of their incorporated solid lubricants, which allow optimal coefficients of friction in the long term - without maintenance.

More about the application

Durable and lubrication-free: plain bearings in glass slat system

For their glass slat system, Fenster Keller GmbH relies on plain bearings from igus. 7,300 bushings made of the material iglidur G are used in the 63 support posts. The bearings are our economical all-rounder, which is ideal for pivoting and rotary movements.

More about the application

Energy chain to power the sliding shutters: compact, lightweight, quiet

The folding sliding shutters from the Swiss company HAWA automatically move in front of the facade and back again. The motor travels with them and therefore requires a flexible power supply. As space is scarce and the entire system should move as quietly as possible, a E2.1 energy chain is used.

More about the application

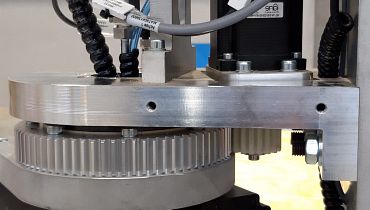

PRT slewing ring bearings in insulation material cutter for automated production of thermal walls

In EBAWE Anlagentechnik's automatic insulation material cutter, PRT slewing ring bearings are used, among other things. They ensure reliable movement of the 3D head on the high-pressure water jet nozzle, which enables diagonal cuts.

Reliable cable guidance for XXL 3D printing robots

Aectual produces sustainable products with its XXL 3D printing robot for the construction industry. Our pneumatic retraction system RSP prevents cables from hanging in the work area without restricting the robot's movement.

More about the application