Precision down to the millimetre ...

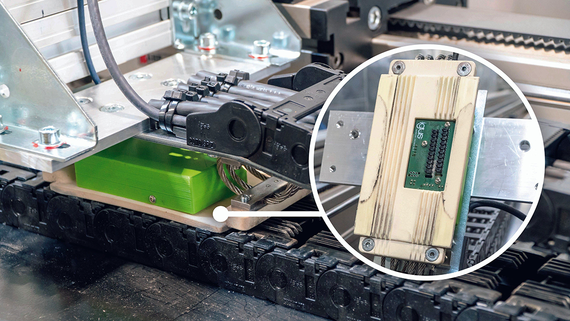

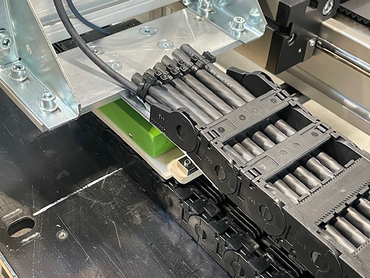

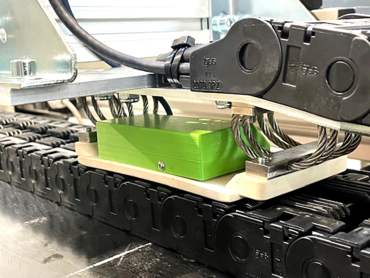

Precise positioning for long travels is no longer a dream of the future with the new travel measuring system. This is because it measures with an accuracy of 1mm. And thanks to the simple installation and user-friendly handling, costs can be saved in several areas.

The new travel measuring system offers extremely high measuring accuracy and therefore offers a significant advantage in automation technology. The integration of wear monitoring offers additional safety and maintenance benefits by monitoring the condition of the energy chain and thus preventing premature failures. The combination of high accuracy, lightness and the option to dispense with alignment makes installation and handling easier and more cost-efficient.

The system can be installed quickly, as there is no need for time-consuming alignment. A further financial advantage is the delivery as a complete unit including mounting bracket, which means that it is not necessary to replace entire chains. It can also be used as an add-on to the autoglide 5.

Overall, the positioning system represents an opportunity to integrate more efficiency and reliability into modern production technology.

The system can be installed quickly, as there is no need for time-consuming alignment. A further financial advantage is the delivery as a complete unit including mounting bracket, which means that it is not necessary to replace entire chains. It can also be used as an add-on to the autoglide 5.

Overall, the positioning system represents an opportunity to integrate more efficiency and reliability into modern production technology.

Arrange an individual product presentation

Tech up

- Extremely high measuring accuracy (accurate to 1mm) thanks to innovative travel measuring system

- Very light

- Integrated wear monitoring of the energy chain (optional)

- Add on for autoglide 5

- Travel measuring system comes as an assembly with mounting bracket, therefore no alignment required

- Replaces a classic positioning system in many cases

Cost down

- Affordable in purchase

- Quick to install, therefore low installation costs

Proof

- With the new travel measuring system, a high measuring accuracy of up to 1mm can be achieved

Sustainability

- Long service life thanks to exceptional robustness

- No need to replace complete chains, the system is supplied as a unit with mounting bracket

Predictive maintenance implemented successfully

i.Cee in practice

Wastewater treatment plants and wastewater operations |

Port and container cranes |

Conveyor and bulk handling

Avoid downtime, extend service life

Avoid downtime, extend service life

Société Nationale des Chemins de Fer Luxembourgeois (CFL)

Customer applications worldwide

Customer applications worldwide

To the application overview

You determine the manner of data transfer and access

Data transfer within your local corporate network (i.Cee:local) or on a secure cloud (i.Cee:cloud)

i.Cee:local

i.Cee:cloud

Smart machine data acquisition ...

... for predictive maintenance concepts

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways. From preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which uses various mobile channels to immediately report any unforeseen change. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Predictive maintenance

White paper on optimising overall equipment effectiveness (OEE)

Clarifies the distinction between condition monitoring and predictive maintenance

This free white paper explains:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems

- What the two systems offer industrial energy supply

Go to free download

... Try it ...

3D data