Savings on cables with the price check

Tech up, cost down. It's our job.

Tech up, cost down. It's our job.

Change motor cables to compact single cores

In various contexts, using individual wires for motors has led to a considerable increase in cable service life. Moreover, cable costs have often been reduced significantly. In this session, we would like to make this knowledge much more widely available and show some clear solutions in this regard.Contents:

- The motor cable as a multi-core cable

- Single cores with their biggest advantages

- What do I need to bear in mind in order to achieve the best results?

Single core – multicore motor cables

In industrial applications, core ruptures or broken shields are a hazard. This often causes machine downtime. igus designs its chainflex cables with mechanically high-quality copper conductors in optimised pitch length to avoid such stoppages. This core structure provides a high load capacity compared to conventional motor cables. From a core cross section of 10mm² it is recommended to switch to single cores for energy chain systems, as these can be used in a smaller installation space, which also benefits the mechanical design of the entire energy chain system.

Cost-effectiveness and compactness are the two primary characteristics that constitute the advantage of a single core over a multicore motor cable. Single cores can be produced at significantly lower cost than the multicore alternative. The small diameter allows faster processing, which ultimately translates to more favourable production costs.

In addition to lowering costs, they also take up less space, which is important when installation space is tight. Both factors make the use of single cores in energy chains in different applications especially attractive.

Example of a calculation for catalogue cables

Multicore cable

Number of cores and conductor nominal cross section: (4G16.0)C

Max. outer diameter: 23mm

Bend radius: 7.5xd

Radius: 175mm

Art.: CF35.UL.160.04 Price: €5.66/m

VS.

Savings: €10.78/m*

Single core cable

Max. outer diameter: 10mm

Bend radius: 7.5xd

Radius: 75mm

Art.: CF310.UL.160.01 Price: €5.13/m

Art.: CF310.UL.160.01 Price: €5.13/m

Art.: CF310.UL.160.01 Price: €5.13/m

Art.: CFPE.UL.160.01 Price: €4.94/m

Total price: €20.33 /m

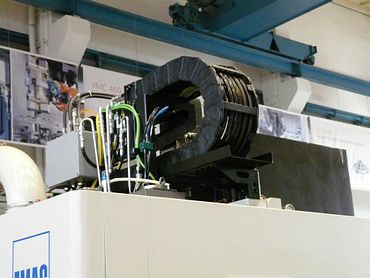

Practical chainflex® application examples

Apart from the price advantage of about 30%, the radius is also reduced. This leads to a decrease of installation space of more than 50%. A further advantage of single cores in the energy chain is that the cable can be better distributed in the chain, which also results in a longer service life.An in-house test laboratory in Cologne, has been completing many hundreds of cable tests every year for 25 years. In many industrial machines small bend radii are required by the motor cable: a bend radius of up to 5xd can also be guaranteed. A service life guarantee of 36 months and up to 10 million double strokes can be issued based on the experience gained in the test laboratory.