SHT drylin® stainless steel linear modules

Robust, corrosion-free and resistant to chemicals

Wherever lubrication must be dispensed with and where machine components are in contact with food, strong cleaning agents or even chemicals, stainless steel is necessary. To minimise maintenance and cleaning effort, igus® has developed linear modules and linear axes for just this scenario - drylin® linear axes made of stainless steel.

Would you like more information about drylin® linear drives or do you need an individual consultation? Our experts will be happy to get in touch with you.

Contact an expert

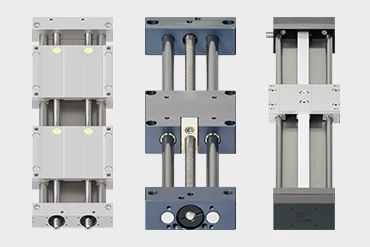

Stainless steel linear axes

SHT-ES

.jpg?crop=no&color=ffffff00&w=370&quality=80)

- Sizes from 8mm shaft diameter to 30mm

- Max stroke length 1500 with SHT-ES-30

- Choice of FDA liners

Request a quote

SLW-ES - Stainless steel version

- Various plain bearing materials

- FDA-compliant with iglidur® A180 plain bearing

- High temperature iglidur® X, up to +250 °C

Visit the shop

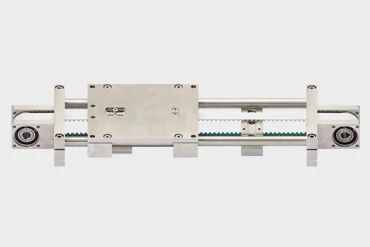

ZLW stainless steel linear axis

- Flat system height of 40mm

- Stroke lengths up to 2000mm

- 304 stainless steel or 316 stainless steel

Visit the shop

drylin® technical accessories

- Accessories for manual positioning

- Format adjustment

- Assembly and fastening options

drylin® overview

- Don't need stainless steel?

- Need a full overview of other drylin® linear systems?

Find out more

Configure your custom linear system online

- Customise your drive system in just a few steps

- Optional configuration of an individual drive pin

- Automatic generation of a 3D model of the linear system

- Export of the linear system in many different 2D and 3D formats

- 2D dimensional drawing of the module as a PDF

- Download parts list as PDF file

- Add to shopping cart and submit order or request a quotation online

Configure your drive

Technical options for the SHT series

The following options can be configured directly online for the SHT product range.

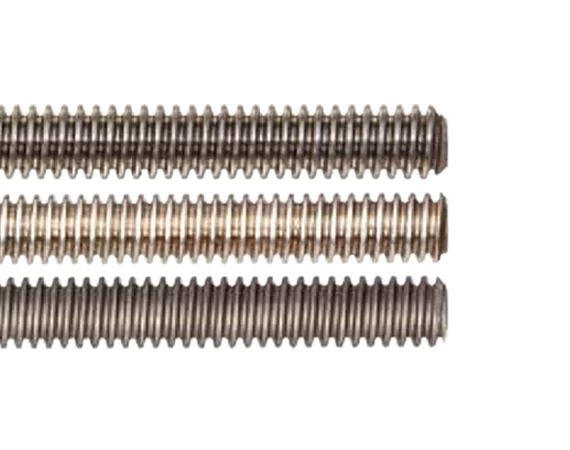

Lead screw design

All drylin® SHT-ES linear modules are delivered with self-locking trapezoidal lead screws made of stainless steel. Hard-coated aluminium is also available upon request. The series can also be configured with stainless steel high helix lead screws (optional). This allows much higher pitches and drive speeds, but without the self-locking feature.

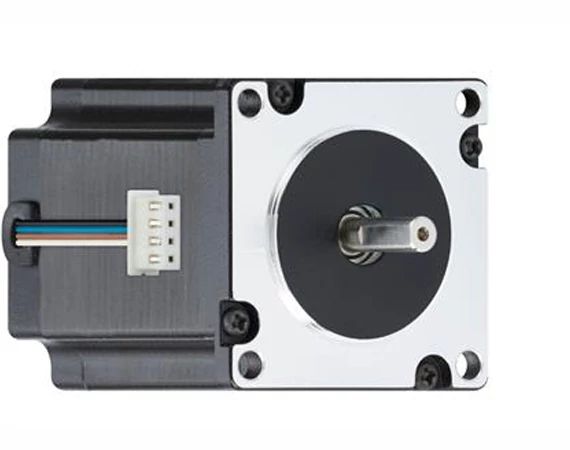

Electric drive systems: electric motors from igus

Whether DC, lead screw stepper or EC/BLDC motors: with its wide-ranging motor shop, igus offers the possibility of equipping linear axis systems with the appropriate motor solutions. In combination with drylin linear axes, which can be ordered completely ready for installation and connection, entire handling systems can be configured. With the powerful motors you solve a wide variety of problems in electric drive technology.

More about stepper motors

Bearing materials

All drylin® drive units bearing points are equipped with lubrication-free and maintenance-free igus® high performance polymers. Options include materials for high-temperature applications up to +180°C (iglidur® X, SHTES series), and for FDA-compliant environments (iglidur® A180).

Not all stainless steels are the same

Hardened stainless steel

Linear axis guides of hardened stainless steel are usually offered in combination with recirculating ball bearing systems and roller bearing guides. The guide system's metal balls require a strong running surface to prevent them from creating grooves. Hardened stainless steel such as AISI 420C, AISI 440B and AISI 440C has a relatively high carbon content (more than 0.5%), which is necessary for hardening in the first place. This means that hardened stainless steel is only somewhat corrosion-resistant. The necessary lubrication for recirculating ball bearing systems and roller bearing guides entails a danger of contaminating products, which is undesirable in many areas.Non-hardened stainless steel

Non-hardened stainless steel has a lower carbon content and inferior hardness, but is much more resistant to corrosion and aggressive cleaning agents and chemicals. Because recirculating ball bearing systems and roller bearing guides are not as well suited to moving on non-hardened stainless steel, a plain bearing system is used. The force exerted at particular points on the rail material is changed to area force. The load on the linear rail is distributed across a greater area, avoiding material wear.The principle: "sliding instead of rolling"

The advantages of plain bearing liners over a recirculating ball bearing system

The high-performance polymer plain bearing liners used by igus need no lubrication or maintenance and are ideal partners for stainless steel linear modules. The combination of plain bearing system and stainless steel linear axis is used in certain applications because of the advantages of linear drive systems.

Customer application examples

Fast and reliable test & measurement

Despite large quantities, the automated systems of Gefra GmbH inspect small components visually for damage. Maintenance-free and lubrication-free components are of great importance in precise visual inspection, and therefore the Gefra GmbH relies on lead screw axes of the drylin drive technology range from igus for adjusting the lighting units.

Linear guides with lead screw drive in test systems