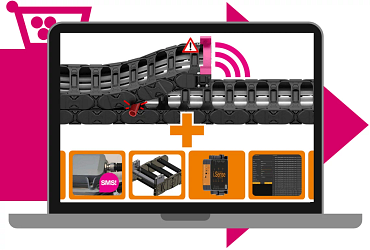

The firmware extension for optimised e-chain service management

A smart step forward in service management: with the addition of a new maintenance management module to the firmware and the connection to the superwise system, service calls and retrofits can be planned intelligently.

The management of maintenance plans is an important part of service management for gliding e-chain® applications. By implementing the maintenance management module and integrating it into the superwise service system, maintenance can be planned intelligently and system downtimes avoided. The firmware extension includes a new maintenance management module that initiates usage-dependent maintenance reminders. With the optional superwise connection, a comprehensive overview of all machine data can be utilised.

The module offers usage-dependent maintenance reminders to ensure that machines are always optimally maintained. The integration of an optional superwise connection expands the possibilities even further by providing a comprehensive overview of all machine data. Integration into existing OT systems or IoT cloud applications can create significant added value and, by detecting potential problems at an early stage, extend the service life of the systems and increase safety.

Intelligent maintenance planning can help to reduce operating costs and increase productivity.

The module offers usage-dependent maintenance reminders to ensure that machines are always optimally maintained. The integration of an optional superwise connection expands the possibilities even further by providing a comprehensive overview of all machine data. Integration into existing OT systems or IoT cloud applications can create significant added value and, by detecting potential problems at an early stage, extend the service life of the systems and increase safety.

Intelligent maintenance planning can help to reduce operating costs and increase productivity.

Arrange an individual product presentation

Tech up

- Management of customised maintenance plans for gliding e-chain applications

- Optional: integration into customer OT systems or IoT cloud applications

- superwise integration enables anomaly detection and timely service and retrofit operations

Cost down

- Prevent system downtimes

- Intelligent service and retrofit planning

Proof

- Ongoing test program in the industry's largest test laboratory for dynamic cable applications

Sustainability

- Avoid unnecessary servicing work

"What should I consider with respect to maintenance when selecting e-chains®?"

10 tips for a "maintenance-friendly" energy chain

What this means in concrete terms and what designers should bear in mind - this small guidebook will provide you with numerous practical tips and tricks.

For free PDF download

Predictive maintenance implemented successfully

i.Cee in practice

Wastewater treatment plants and wastewater operations |

Port and container cranes |

Conveyor and bulk handling

Avoid downtime, extend service life

Avoid downtime, extend service life

Société Nationale des Chemins de Fer Luxembourgeois (CFL)

Customer applications worldwide

Customer applications worldwide

To the application overview

Smart machine data acquisition ...

... for predictive maintenance concepts

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways. From preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which uses various mobile channels to immediately report any unforeseen change. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Predictive maintenance

You determine the manner of data transfer and access

Data transfer within your local corporate network (i.Cee:local) or on a secure cloud (i.Cee:cloud)

i.Cee:local

i.Cee:cloud

White paper on optimising overall equipment effectiveness (OEE)

Clarifies the distinction between condition monitoring and predictive maintenance

This free white paper explains:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems

- What the two systems offer industrial energy supply

Go to free download

More time for your own ideas ...

... thanks to less downtime with igus i.Cee

In automotive production, the line never stops. Collaborating robot arms for assembly and welding are in continuous use, as are all the components that supply them with energy and data. It is in just such environments that intelligent concepts such as predictive maintenance make the most sense. For a new Industry 4.0 project or for efficiency-driven retrofitting, our smart plastics solutions are available as universal modular systems and can be individually adapted to any system.Predictive maintenance in automotive production

... Try it ...

3D data