Maintenance-free igus® bearings on SRAM derailleurs

If you want to deliver maximum performance with your mountain bike, in addition to talent, riding technique and lots of training, you also need MTB components that deliver optimal performance and support you. And it doesn't matter whether you compete in the Olympic Games, the UCI MTB World Cup or the Red Bull Rampage, you need to rely on your components on the bike. Even if your ambitions are a bit lower and you "only" want to perform in your favourite bike park or on your home trails, there is hardly anything more annoying than having to start the journey home with a technical defect. In order to avoid this fate, SRAM relies on the high-quality plain bearings from igus for the vast majority of derailleurs.

Advantages of igus plain bearings for bicycles:

- Lightweight and cost-effective

- Lubrication-free and maintenance-free

- Resistant to oil, dirt and water

- Corrosion-free and long-lasting

- Predictable service life

Our plain bearings are resistant to water, mud, sand and oil

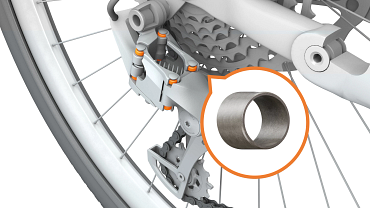

Derailleurs on mountain bikes are subjected to extreme loads. It doesn't matter whether it's mud, dust, water or a combination of all - the environmental influences on this kind of trails are extreme. In addition, there are root carpets, blocked passages, berms, and banking bends. And what would a really nice single trail be without airtime? Well, it's boring! So, there are still plenty of jumps to be made. When you press the shift lever, you naturally expect the chain to land in the appropriate sprocket of the cassette as quickly as possible. This is exactly where the iglidur G plastic plain bearings from igus come into play, because in order to change gears, the derailleur has to move to the right position extremely precisely and quickly. It does this by moving the guide roller of the mountain bike derailleur to the right place through a parallelogram mechanism.

Since the cassette's sprockets are arranged side by side very close to each other, especially with a 12-speed gear system like SRAM's Eagle drives, the rear derailleur has to be in exactly the right position. Otherwise, even small deviations could result in chain noises. Due to the no longer exact movement of the chain on the sprockets, there is also increased wear on the chain and cassette. In the worst case, the chain could jump onto the wrong sprocket. The derailleurs from SRAM have iglidur G plastic plain bearings from igus at all pivot points to ensure this level of precision.

What are the advantages of igus plain bearings on mountain bike derailleurs?

The plain bearings from igus have a number of advantages over direct bearing in plastic, aluminium or brass bushings since they require no external lubrication and are resistant to dirt, sand, dust, oil and water, and moreover, they are exceptionally lightweight. In contrast to the old bushing solution, the igus bearings enable high precision with extremely low friction, which makes them almost indestructible when used on the derailleur. The economic efficiency is mainly determined by the long service life of the plain bearings, which is predictable with our online tools. Since the igus plain bearings do not have to be lubricated, there is no need to maintain the bearings, which is otherwise quite difficult at this point. And the bearings are of course absolutely rust-free. So you can slog through mud and slush in the worst rain without having to worry about damaging the derailleur bearings. Here you can already see how practically tough our plain bearings are when they are used on the derailleur.

What about SRAM derailleurs for racing bikes?

Of course, the derailleurs on racing bikes are also exposed to high loads. It doesn't matter whether it's one of the three major national tours, the Giro, the Tour de France or the Vuelta, at one of the five monuments of cycling, or at major events such as the Olympics or world championships - professional cyclists need to rely on their components. That's why SRAM relies on igus plain bearings here too. Just like MTB derailleurs, these are impressive because they do not require any lubricants, and are therefore maintenance-free, lightweight and have a long service life. This means that both professionals and amateur athletes can conquer the steepest ramps and the most beautiful serpentines.

Do our plain bearings fit into your products?

Do you work in the bicycle industry and are wondering which of our plain bearings can be used in your products? Do you also want to know whether we can manufacture high-performance plastic bearings that are individually adapted to your application and thus enable you to further distinguish yourself from the competition with our know-how? Of course, more than 50% of the plain bearings used by our customers are custom-made. Let us offer you some meaningful tips - we can be reached by phone, e-mail or online chat. Together we will find a solution!