Test reports of the motor cables

Discover all our test reports on the durability tests for our motor cables here.

Motor cable CF270.UL.25.04.D

| Test number: | 4831 |

| Bend radius: | 100mm (factor 9.1 x d) |

| Service life: | more than 18 million strokes |

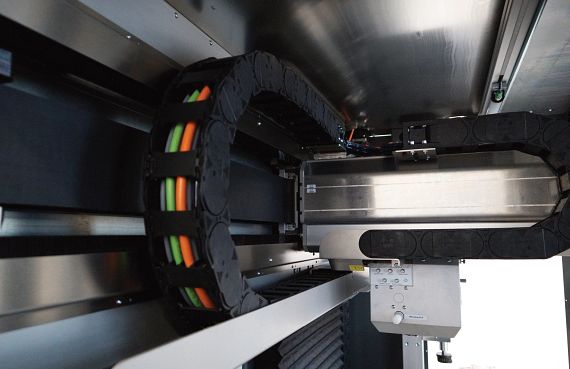

In this test, the life expectancy of the CF270.UL.25.04.D was to be analysed in an e-chain with a 100mm radius.

The test showed that the expected service life of the CF270.UL.25.04.D motor cable can withstand more than 18 million strokes and can therefore be used as a reliable supply cable for motors.

The test showed that the expected service life of the CF270.UL.25.04.D motor cable can withstand more than 18 million strokes and can therefore be used as a reliable supply cable for motors.

Use of the CF270.UL.D in practice

Process automation in the automotive industry saves time and money. Automation technology is essential in the production line, where it requires a great deal of drive technology with motors and converters. From structural work to the paint shop to final assembly, systems are in different environments and come into contact with different materials. All of these areas require motor cables that meet the strict requirements of the automotive industry.

Download full test report

Motor cable CF38.250.04

| Test number: | 4904 |

| Bend radius: | 175mm (factor 6.5 x d) |

| Service life: | 43 million strokes |

In this test, the life expectancy of the CF38.250.04 in an e-chain with a 175mm radius was to be analysed.

The test has shown that the expected service life of the CF38.250.04 motor cable can withstand 43 million strokes and therefore has large reserves.

The test has shown that the expected service life of the CF38.250.04 motor cable can withstand 43 million strokes and therefore has large reserves.

Use of the CF38 in practice

Cable failures are certainly never desired. However, a cable failure in crane and trolley travels is unthinkable. Reliability and maximum safety are required here. The motor cables used are therefore exposed to major challenges. Temperatures of -40°C to +80°C are not uncommon. In addition, there are usually long travels and therefore high loads due to continuous use and dust. The motor cable used must be able to withstand all these conditions.Download full test report

Motor cable CFROBOT7.25.04.C

| Test number: | 3698 |

| Cable type | Motor cable |

| Test parameter | 105mm/+/-180°/m |

| Service life: | 120 million cycles |

This test was carried out to analyse the life expectancy of the CFROBOT7.25.04.C in a triflex.

The test result of over 12 million cycles confirms that the cable fulfils the requirements for drive technology in robotics.

The test result of over 12 million cycles confirms that the cable fulfils the requirements for drive technology in robotics.

Using the CFROBOT7 in real life

The aim of the test was to determine the service life of the twistable motor cable of the CFROBOT7 robot cable family. The CFROBOT7 is required to reliably withstand continuous movement, such as in a robot with a torsion of +/-180° as it is found in the automotive industry.In these applications, it is often the case that the robots are permanently in motion and the cables are therefore constantly exposed to this torsion. Thanks to an enclosed overall shield and the robust PUR outer jacket, this cable is ideal for movements in the 3D range.

Download full test report