motion on demand

3D printing, CNC production & tolerance check

The best solutions for your individual special parts

Do you need a completely customised component for your application? Then our service motion on demand is just right for you! You can put together your desired solution here for all manufacturing processes offered by igus and for all suitable motion plastics materials. We offer you three different tools with which you can implement your solution quickly and easily. Get to know these tools for motion on demand now.

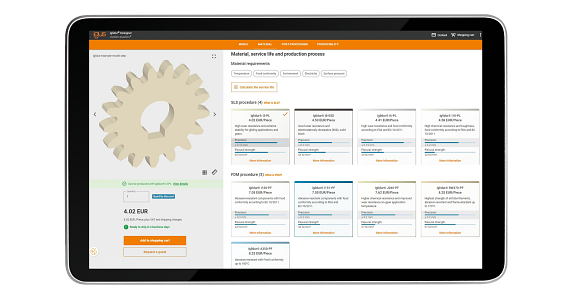

The most cost-effective solution from all motion plastics materials and igus manufacturing processes

Individual application solution on a single page

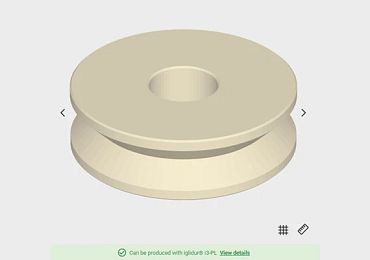

At rocket speed to the custom-made component: that is the basic concept of the 3D printing service from igus. Just upload the 3D model, and manufacturability is checked automatically, prices and delivery times are calculated, and the component can be ordered directly online. You can also calculate the expected service life of the component in your individual application.To the industrial 3D printing service

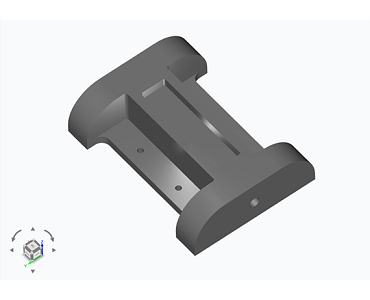

Request or order turned and milled parts conveniently and quickly online

Price information and feasibility analysis in one tool

Request or order turned and milled parts from iglidur online! With our CNC Service 2.0, you simply upload your 3D model and you will immediately receive transparent price information and an automated feasibility analysis. Our tool checks the 3D model geometry and gives you feedback on production-critical points as well as on high complexity or feasibility problems.To the CNC service

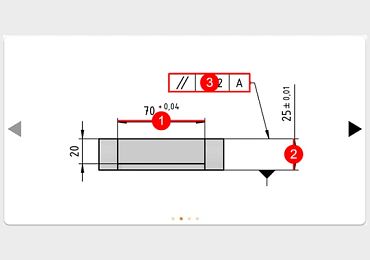

Revolutionary recognition of 2D drawings with tolerance recommendations

Testing for the suitability of plastic-compatible machining

You have finished designing a machined component, but are not sure whether the tolerances and surface specifications you have provided are suitable for plastics? Our tool checks all the information in the drawing with regard to the production standards appropriate for plastics. Tolerances are marked visually and suggestions for correction are displayed.To the tolerance check