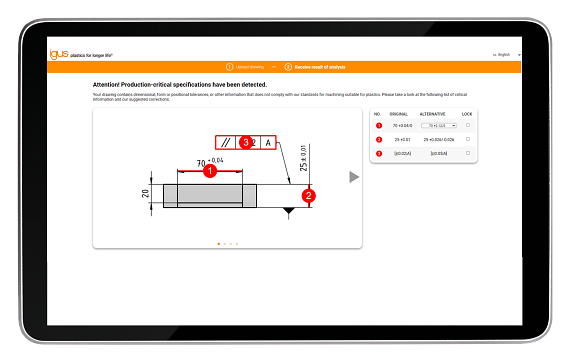

CNC tolerance check

You will receive direct feedback as to whether your turned and milled parts can be made according to the requirements stated on your technical drawing, or whether something needs to be adjusted.

It's simple:

1. Upload technical drawing (.pdf, .jpg or .png).2. Receive analysis results and suggested corrections

3. Simply download the corrected drawing and/or request support from our team

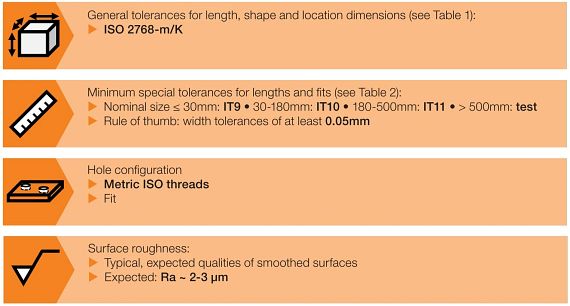

igus® manufacturing standards

Plastic-compatible tolerancing of CNC components

Plastic has its own characteristic behaviour, which must be taken into account during machining. Our manufacturing standards ensure that your turned and milled parts are processed in a way that is suitable for plastics.

We recommend compliance with the following standards (see diagram right) so that your components can be manufactured as quickly as possible.

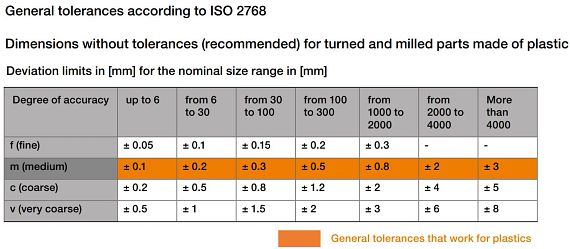

General tolerances and special tolerances (lengths)

Plastic-compatible tolerancing of CNC components

For lengths, the general tolerances according to ISO 2768 (degree "medium") are recommended, as shown in the table on the left.

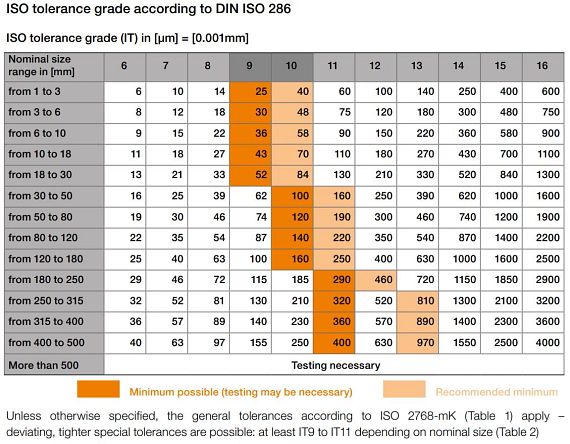

Deviating, tighter tolerances are possible up to a certain ISO tolerance level. The minimum possible and recommended tolerances can be seen in the table on the right. (Although even tighter tolerances would be feasible on the machine side, they would not be possible to maintain with plastic components over time and would therefore not make sense from a technical point of view).

Design guide

Our free white paper helps you with the key principles for designing your CNC components. We give you 12 helpful tips for your turned and milled parts - so you can achieve a design that is optimised for economy and production.When and why CNC machining is worthwhile for your components

Large variety of materials and material quality:

The large variety of materials of our iglidur® bar stock guarantees optimum, tribological component specifications for any application.

High surface finish:

Due to the method used, CNC machining produces good surfaces - iglidur® components normally also do not need any special reworking of the sliding surfaces.

Precise component dimensions with tight tolerances:

You receive dimensionally accurate components with tightly toleranced dimensions and fits. Narrow tolerance ranges (up to tolerance grade 9 acc. DIN ISO 286) are usually feasible. Tolerance widths of 0.05mm are therefore not a problem.