Linear bearings for simple filling level adjustment in folding and gluing machines

Light, lubrication-free, robust: simple and reliable format adjustments in packaging machines

Nowadays, product information is increasingly easily obtained from the Internet. This also applies to machine components and purchased parts in order to save process costs. When designing customer-specific folding box gluers, the special machinery manufacturer Bernhardt Maschinenbau oHG relies on lubrication-free and maintenance-free linear plain bearings.Profile

- What was needed: drylin W linear rails, drylin T profile rails, drylin SLW lead screw linear systems

- Requirements: Simple format adjustments, robust and maintenance-free components that must work lubrication-free due to cellulose in the air

- Industry: Packaging industry

- Success for customers: The lightweight and lubrication-free plastic creates flexible system modules. The drylin linear technology works reliably over the long term, even in two and three-shift operation.

Problem

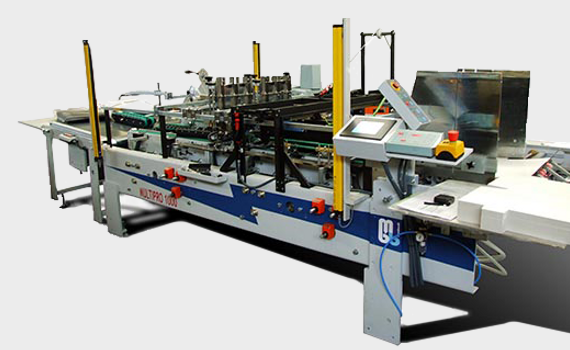

One of the focal points of Bernhardt Maschinenbau oHG is the design of the folding and gluing machines. These are suitable for processing materials between 180g/m² and 600g/m². For example, the machines can be used to fold and glue CD covers, digi-packs, folding boxes, flight ticket bags or presentation folders at a speed of up to 300m/min. Due to their modular design, additional order and dispensing systems can also be connected at a later date and used flexibly. Customer requests are quickly addressed; for example, the manufacturer now offers a fast filling level device with a capacity of up to 5,000 cycles per hour. A prototype plant for 250,000 boxes was built, which must be able to quickly and easily adapt to new requirements for machine operators. Environmental conditions are also not always easy. Because paper contains cellulose. The ubiquitous paper dust, combined with humidity, can quickly combine to form a sticky mass that could disrupt the process. Robust and, above all, maintenance-free technology is therefore important.In order to avoid production downtimes and unnecessary downtimes of the folding and gluing machines, high demands are placed on the machine elements used. Freedom from maintenance and lubricants, resistance to dirt, a long service life and, of course, economic efficiency play a very important role.

Solution

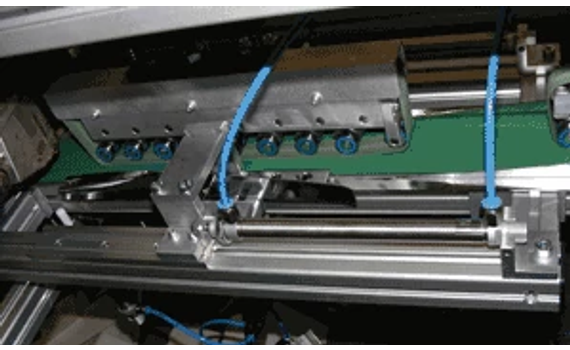

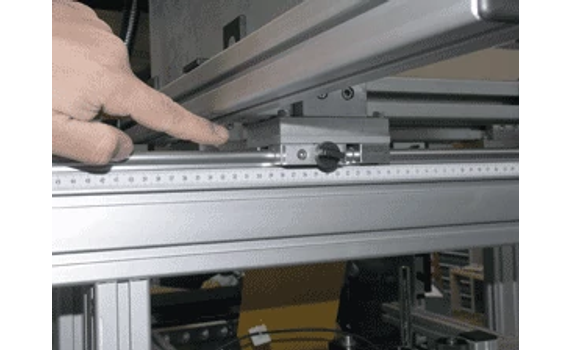

In the adjustment units of special attachments, the company relies exclusively on drylin linear plain bearing systems. Since the machine frames are not always in one place at the customer's site, plastic, which is very light in comparison, scores higher points compared to the steel guide. There is also the appearance. The system profiles are the same in all folding/gluing machines. The aluminium frame and the aluminium rail material of the drylin linear bearings harmonise in shape and colour. Another decisive factor was the price, which convinced the plant manufacturer just as the cleanliness of the lubrication-free bearings that prevent contamination of the product in the machine.Even with maximum capacity utilisation in two and three-shift operation, the systems run smoothly today. Flexible drylin W guide systems with a linear lead screw or combined as a compact drylin SLW lead screw linear system are used in the filling level devices. In addition, robust drylin T profile rail guides prove their strength. The iglidur J has proven itself as a material in all cases. It was specially developed for linear applications in connection with hard-anodised aluminium surfaces.

In a current project, a silicone paper dispenser, the drylin W has likewise proved itself. With the dispenser system, up to 10,000 siliconised paper strips can be applied in a position precisely per hour. The dispenser is installed, among other things, in folding/gluing machines and is used for the production of cardboard shipping envelopes, for example. With a maximum space requirement of 10mm, a large number of axes are fitted with linear plain bearings. With them, the required speeds of 40m/min, which can be extended to up to 150m/min, can be achieved completely without any problems over very short distances.

Max Steiner, Head of Design at Bernhardt Maschinenbau oHG