drylin® R linear shafts systems

drylin® R linear bearings are based on highly wear-resistant polymers developed especially for linear technology. The dimensions are compatible with standard ball bearings. The special shape of the shaft guides and bearings guarantee toughness and precision – even under extreme environmental conditions.

- 100 % lubrication-free

- Large variety of choice in housing shapes

- Shafts, shaft end blocks and accessories available from stock

- 8 different shaft materials

- Replaceable liners

- Our rails can be joined together to make unlimited lengths, unlike ball bearing systems.

Visit the shop

drylin® R products

Linear shafts

- Made of aluminium, steel or stainless steel

- Corrosion-free

- High load capacity

- Click here for information on linear shafts

Visit the shop

Linear shaft housing

- Easy assembly

- High static load

- Liner replaceable

- Click here for information on linear shaft housings

Visit the shop

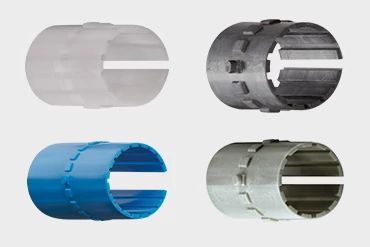

Linear plain bearings

- Closed or split

- Compensates for alignment errors

- Open for supported shafts

- Click here for information on linear bearings

Visit the shop

Linear housing with flange

- Anodised aluminium housing

- With round or square flange

- Also available with floating bearing function

Visit the shop

drylin® overview

- Unsure which system is best for you?

- Need more information on our drylin products?

- Back to overview page for all drylin® products

Find out more

Configure a complete system

You can use the drylin® linear guides expert to quickly and easily configure an individual linear guide for your application in just five steps.

Configure online now!

Fact check: plain bearings vs. rolling bearing

Properties | Characteristics of igus® plain bearings | Characteristics of rolling bearings | Technical data of igus® plain bearings | Technical data of rolling bearings | Especially relevant for the following industries: |

|---|---|---|---|---|---|

| Precision | + | +++ | 0.02 - 0.15mm | 0.001 - 0.01mm | Machine tools, CNC processing, electronics manufacturing |

| Completely lubrication-free | +++ | + | Medicine, packaging, food, cleanroom, consumer goods | ||

| Maintenance-free | +++ | + | For many different branches of industry | ||

| Weight advantage | +++ | + | Aluminium approx. 2.7g/cm³ Polymer approx. 1.5g/cm³ | Steel approx. 7.8g/cm³ | Handling, automation, laboratory, leisure time |

| Highly dynamic responsiveness in the case of low loads | +++ | + | Packaging, handling, automation | ||

| Highly dynamic responsiveness in the case of high loads | + | +++ | Packaging, handling, automation | ||

| Stroke length variance | +++ | ++ | Camera technology, textile | ||

| Coefficient of friction | + | +++ | 0.15 - 0.3 µ | 0.001 - 0.05 µ | Manual adjustment, pivoting |

| Sensitivity to dirt | +++ | + | Packaging, stone, textile, paper, painting equipment | ||

| Noise dampening ¹ | +++ | ++ | 45 dB | 60 dB | Medicine, laboratory, furniture |

| Cost advantage | +++ | ++ | For many different branches of industry | ||

| Protection against corrosion | ++ | + | Filling systems, chemicals, food | ||

| Magnetism | + | +++ | Plastic, aluminium | Steel | Medicine, testing instruments |

| Chemical resistance | +++ | + | 1.4751 + iglidur® X | 1.4112 | Medicine, food, electroplating, filling systems |

| Compatibility of the modules | +++ | + | Jig construction, assembly line automation | ||

| Quiet operation without any vibration | +++ | ++ | Camera technology, inspection, medicine, 3D printer | ||

| Short-stroke suitability | +++ | + | Textile, handling | ||

| Easy to fit and quick replacement | +++ | + | Jig construction, assembly line automation | ||

| Rigidity | + | +++ | Machine tools, CNC processing, electronics manufacturing | ||

| Long travels of more than 10m | ++ | + | Camera, material handling, logistics | ||

| Temperature-resistant | +++ | + | up to +250 °C | Chemicals | |

| Smooth running | + | +++ | Manual adjustment | ||

| Maximum acceleration ² | +++ | ++ | 50m/s² | 15m/s² | Automation, handling |

| Maximum speed ² | +++ | + | 30 m/s | 5 - 10m/s | Automation, handling |

1) Measured in the igus® laboratory, 400mm stroke, manual adjustment

2) When subjected to low loads, depending on installation size 0.1 to 5kg

Characteristics: +++ strong ++ average + weak

Application examples

drylin® R in commercial vehicle technology

drylin® R transfers the steering movement from the front to the rear wheels.To the article

drylin® in the laboratory

The materials used here from the drylin® R product range easily withstand the extreme conditions.To the article

drylin® R on wooden shafts

A height-adjustable, tiltable wooden desk.

More application examples

Take a look at some more application examples.To the articles

Frequently asked questions about drylin® R

What is drylin® R?

drylin® R is the "round" section of the drylin® family. The standard round hollow and solid shafts are found here, alongside a variety of housings and carriages.

Where can I use drylin® R products?

drylin® R can be used in a large variety of applications, even extreme environments. You can check the suitability using the configurator tool on our website.

Why use igus® drylin® R?

The drylin® R required no lubrication, comes in a huge variety of materials and sizes and are standard off the shelf products.

Read more FAQ's here

Selected application examples

drylin® R in commercial vehicle technology

Tough & maintenance-free

drylin® R linear plain bearings are used in the bus trailers manufactured by Göppel Bus GmbH. They transfer the steering movement from the front to the rear wheels.

drylin® R linear shafts in commercial vehicle technology

drylin® R in laboratories

Stainless steel shafts with fixed flange bearings and plain bearing for laboratory press

This laboratory press is in no way an off-the-shelf product but a customised solution. Tough stainless steel shafts and temperature-resistant and lubrication-free polymer bearings ensure a high level of availability of the heart of the machine. The materials deployed here from the drylin® R product range easily withstand the extreme conditions.

drylin® R shaft guide in the laboratory press

drylin® R in an ultra-high vacuum apparatus

In use in research for precise measured values

This apparatus can be used to measure the adsorption heat of small organic molecules (e.g. isopropanol) in single crystals (e.g. platinum). In order to guarantee that measurements are exact as possible, the precise components used in the apparatus are also able to withstand high temperatures of up to 180 °C.

drylin® R in an ultra-high vacuum apparatus

drylin® R in parting-off grinder

Aluminium shaft and plastic bearings for precise linear guidance

drylin® R aluminium shafts are used in this grinder to guide the cutting table. The linear plain bearings on the basis of high-performance polymers operate completely without lubricants. This makes the shaft guide resistant to dirt accumulations while providing smooth operation.

drylin® R shaft guide in film saw

Precise positioning for clean cuts

This saw cuts plastic films wound on spools. The saw blade can be moved over the entire length of the spools and saw into the film. The movements of these two axes are guided by supported shafts and shaft guides from the drylin® R range. Precise positioning for clean cuts and a fully maintenance-free plant were of importance here.

drylin® R shaft guide design

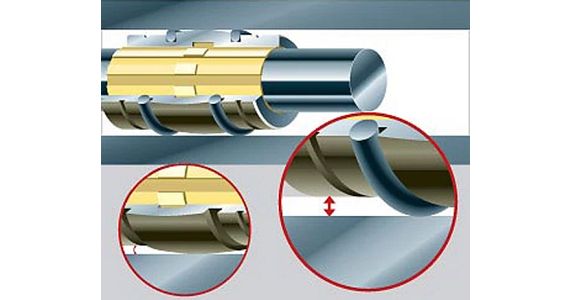

Floating bearing for shaft guides

The drylin® R floating bearings offer great advantages in applications with parallel shafts. With their geometry, they are able to compensate for alignment and parallelism errors and should be used on the shaft located furthest from the drive mechanism.For the design tip