Lubrication-free lead screw drives means more hygienic

How can unwanted contaminations be avoided in laboratories?

In medical technology, metallic lead screw nuts continue to be the norm. However, they mostly require frequent maintenance and lubrication. In this process, dust and dirt particles can easily stick to the used lubrication. This leads to considerable contamination and a significantly higher wear compared to a system that works in dry operation. Furthermore, the metallic lead screw nuts can corrode quickly in humid environments.

The lubrication-free and maintenance-free drylin lead screw technology is used in medical technology and convinces due to its many advantages. It is absolutely free from lubrication and maintenance and can also be used in corrosive environments without problems.

How igus lead screw technology can reduce costs in rehabilitation equipment

Metal lead screw nuts are more expensive than their plastic counterparts. If you replace your metal lead screw nuts with dryspin technology, with the same connection sizes, you can save up to 50.9% acquisition costs. Tests have revealed that the wear rate is reduced by up to 25% and service life increased by 30%.

Products for medical technology

dryspin® lead screw technology

Lead screw nuts

► Available in six different materials► Very different designs

► Save up to 50.9% in costs

Go to the online shop

Lead screws

► Four different materials► High helix, trapezoidal and metric threads

► Up to 30% longer service life

Go to the online shop

Special geometries & accessories

► Special designs for every application► Accessories for lead screw nuts and lead screws

► Our experts are happy to advise you in person

Go to the online shop

What should you do with unwanted axial clearance?

Our lead screw nuts reduce clearance

To reduce the unwanted axial clearance, in addition to the correct choice of material, a pretension mechanism has proven to be an effective measure. For our dryspin® high helix threads and trapezoidal threads there are three versions with pretension:► Zero-backlash lead screw nuts

► Low-clearance lead screw nuts

► AB lead screw nuts

Reduce axial clearance here

25 % less wear

Our lead screw technology convinces in the test laboratory

The evaluation of the wear test for the product with the dimensions 10x3 made of stainless steel 1.4301 showed that our dryspin thread Ds10x3 can achieve an up to 25% lower wear rate, an up to 25% longer service life and greater efficiency compared to the competition and the trapezoidal thread Tr10x3.Go to test reports

30% longer service life

Thanks to the unique dryspin technology

The larger spaces between the individual dryspin threads result in a higher share (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.Find out more about dryspin technology

100% lubrication-free and maintenance-free

Ideally suited for areas sensitive to hygiene

From laboratory equipment and hospital facilities to rehabilitation systems - the freedom from lubrication and maintenance of the lead screw drives enables use in almost all medical areas.By using the tribologically optimised iglidur high-performance polymers, dust and dirt cannot sick to the lead screw drive. The dryspin technology is also one step ahead in humid environments: it is 100% corrosion-free. Therefore, a smooth operation is guaranteed throughout the entire application. Discover maintenance-free dry operation in the dryspin lead screw technology online shop.

Quiet, & vibration-free

Important factors when dealing with patients

In medical facilities, such as hospitals, operating rooms or laboratories, it often has to be particularly quiet. Hence, the components incorporated in the applications have to run quietly. Here too, dryspin technology has proven itself as the perfect alternative to conventional metal lead screw drives. Due to the rounded tooth geometry, the contact area between lead screw and nut is reduced. This means that the dryspin lead screw drives operate almost silently without vibrations even under high loads. Our online shop offers lead screw drives in a variety of different shapes and sizes.

50.9% lower costs

dryspin technology convinces in any comparison of prices. It not only distinguishes itself due to its several technical advantages over its metallic counterpart, but is also 50.9% more cost-effective.

Cost down with dryspin lead screw drives

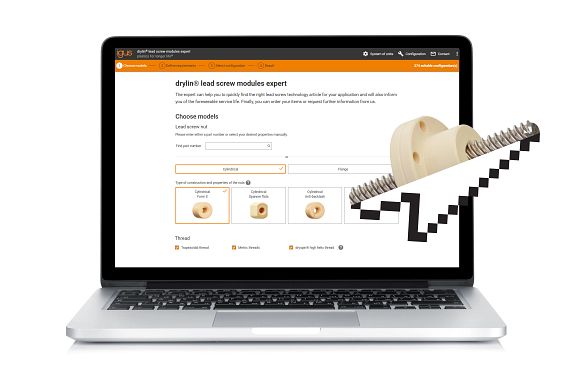

Customer-specific designs configurable online

The expert can quickly help engineers find the right lead screw system part for their application and will also predict service life.

The configurator enables engineers to quickly find the right lead screw and machine the pins from both sides. The application generates a dimensioned drawing of the configuration.

To the engineer's tool box

Free dryspin® sample

Your own lead screw drive with the most important information for medical technology at a glance:► Free from lubrication and maintenance

► Higher efficiency and longer service life

► Resistant to media

► Quiet, vibration-free operation due to rounded tooth geometry

► Service life predictable online

Order sample here

Application examples of our clients

in the area of medical technology

in the area of medical technology

Filling systems for reaction vessels

- What was needed: a clean filling, which does not have to be sterile, but must be very clean, and a low overall weight of the system

- Requirements: cleanroom suitability, freedom from lubrication and maintenance, lightweight, precision, fast availability

- Material: trapezoidal lead screw nut made from iglidur W300, trapezoidal lead screw nut made from AISI 304, drylin miniature guides

- Industry: medical technology

Find out more here

Laboratory unit for handling liquids

- What was needed: an impeccable application of igus products without development of dirt in addition to high efficiency and a fast feed

- Requirements: suitable for hygiene-sensitive areas, lubrication-free, maintenance-free, low coefficients of friction, high pitch, space-saving, quick and easy to replace, lightweight, precise, quickly available, cost-saving

- Material: drylin trapezoidal lead screw made of 1.403 stainless steel and drylin trapezoidal lead screw nut made of iglidur high-performance plastics

- Industry: medical technology

Find out more here