Full control in all bearings ... with the smart i.Sense BRG mini-sensor

New low-cost sensor technology allows cost-effective real-time condition monitoring for (almost) any igus® plastic product ... including direct connection to the PLC system control

The new i.Sense BRG mini-sensor gives you full control. This innovation enables you to make (almost) any igus plastic product smart; as a user, you benefit from real-time condition monitoring, including digital evaluation capability for recorded machine data. It then works with the i.Cee module to output predictive maintenance recommendations and service life statements.The whole thing is realised by a wired 2.5mm x 4mm abrasion sensor that is simply inserted into the stressed friction points in the plastic. Skilful geometric positioning of these elements allows clear statements to be made about product service life in the event of an electrical interruption or change in resistance. It doesn't matter whether the igus starting product is a 3D printed part, an igubal spherical bearing, or a customised iglidur milled part. The percentage status messages can then be read out directly from the PLC machine control system via the cable connection. Sales prices can thus be less than EUR 250.

Intelligent condition monitoring implemented successfully

i.Sense from smart plastics in practice

Wastewater treatment plants and wastewater operations |

Port and container cranes |

Conveyor and bulk handling

"Less effort, greater availability"

"Less effort, greater availability"

Dipl.-Ing. Fabian Wilhelm, Project Manager for AOS Stade GmbH

Customer applications worldwide

Customer applications worldwide

To the application overview

"What should I consider with respect to maintenance when selecting e-chains®?"

10 tips for a "maintenance-friendly" energy chain

What this means in concrete terms and what designers should bear in mind - this small guidebook will provide you with numerous practical tips and tricks.

When do I need a smart condition sensor like the i.Sense BRG?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

Live condition monitoring in every bearing

i.Sense BRG for everyone

A defective bearing point can ruin the day, not only for farmers, but for any machine operator. Machine failures and downtimes are among the biggest cost drivers in industry. It is therefore important for maintenance personnel to act in good time to prevent unplanned stoppages.igus smart bearing products are great for especially sensitive or hard-to-reach spots on a machine, since they allow the bearing's condition to be assessed at any time. The sensor can be used to monitor each machine wear part remotely – and this could benefit many other motion plastics applications in the future.

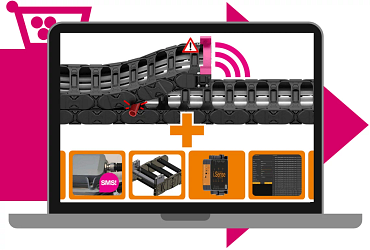

Integration into your network environment

Since the new i.Sense BRG mini-sensor is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. These data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

General smart plastics overview

Insight into the entire igus Industry 4.0 product portfolio

Table of contents for this free brochure:

- Condition monitoring (i.Sense)

- Condition monitoring systems

- Advantages of condition monitoring systems

- Condition monitoring application examples

- Predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart factory concepts

... Try it ...