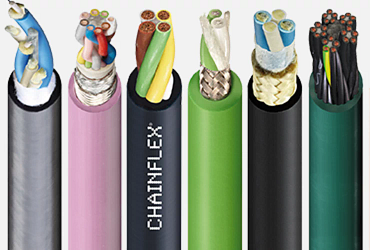

chainflex® cables for use in the offshore industry

chainflex® cables with "DNV" approval and NEK 606 MUD-resistant approval for maritime use

To allow cables to be used for moving applications on ships and offshore applications without the need for time-consuming and cost-intensive special approvals, igus GmbH and the DNV classification company developed a new test procedure. As a result, a total of 387 chainflex cables from igus have now received type approval for permanent movement in e-chains.This makes them the first cables in the world specifically for applications in energy chains to receive this approval.

Contact an expert

Approvals & standards

The importance of the approvals & standards for chainflex cables

In challenging environments like offshore and marine applications, the reliability and durability of your cables is essential. This is where the MUD NEK 606 and DNV approvals and standards come into play.These ensure your cables meet the best performance and safety requirements.

Why are these standards and approvals so important?

Both the NEK 606 MUD-resistant and DNV are available in most of our PUR jackets, which means this range of cable are equipped to handle the challenges of offshore applications.

We also offer other cables which are DNV-GL approved in our TPE range.

MUD-resistant according to NEK606

The NEK 606 MUD-resistant standard is a Norwegian technical specification designed for the marine and offshore industry. It covers a range of cables that are MUD- resistant, meaning they can withstand exposure to hydrocarbon-laden drilling mud used in offshore drilling operations.

This resistance is key because drilling mud can have detrimental effects on the cable, which could ultimately lead to cable failures and safety hazzards.

Cables which comply with the NEK 606 standard are tested on their ability to last in harsh conditions with extended exposure to mud at high temperatures.

DNV approvals

In order to supply safe and suitable products for these applications, igus worked with the DNV classification company to develop a new testing procedure and to have their chainflex cables certified.The DNV is a globally recognised certification body that sets the standards for safety, quality and environmental sustainabilty in the offshore and marine industry.

Cables that are DNV certified have gone through harsh and rigorous testing to ensure they meet the highest standards of safety and reliabilty.

Development of new testing procedures necessary

Classification companies such as DNV typically issue approvals that are in line with international standards. In many cases, particularly concerning the materials, these refer to special specifications with regard to fire behaviour or other requirements.

Over a long certification time of more than three years, with very different areas of investigation, the special knowledge of the two companies led to a cable designation for use in energy chains on ships and in offshore applications for the very first time.

Our chainflex® cables

CF77.UL Control cable

- Cores wound in bundles for a long service life

- PUR unshielded control cable

- Large range of core cross section combinations

Visit the shop

CF78.UL Control cable

- Cores wound in bundles for a long service life

- PUR shielded control cable

- Large range of core cross section combinations

Visit the shop

CF240.PUR Data cable

- Wound in layer cable design

- PUR shielded data cable

- Best EMC properties due to high shield coverage

Visit the shop

CF211.PUR Data cable

- Twisted pair cable design

- PUR shielded data cable

- Best EMC properties due to high shield coverage

Visit the shop

CF112 Data cable

- Twisted pair with a pair shield

- PUR shielded data cable

- The highest EMC properties due to high shield coverage

Visit the shop

CFBUS.PUR Bus cable

- Simple selection matrix for a good overview

- PUR shielded cable following BUS protocols

- Reliable data transmission

Visit the shop

CFLG.LB.PUR Fibre optic cable

- For long distances and transmission of large data

- PUR outer jacket

- Several options of number of fibres and fibre size

Visit the shop

CF111.D Measuring system cable

- Electrical design according to manufacturer

- PUR shielded cable designed for <10 M

- Halogen free and flame retardant

Visit the shop

CF113.D Measuring system cable

- Electrical design according to manufacturer

- PUR shielded cable designed for 100 M

- Halogen free and flame retardant

Visit the shop

CF27.D Servo cable

- Various structures with one or two pair

- Innovative shield pair structure

- Special core insulation for greater current flow

Visit the shop

CF280.UL.H Hybrid cable

- Specifically designed for drive manufacturers

- Wide range of core configurations

- One cable technology

Visit the shop

CFSPECIAL.532 Data cable

- Data cables for top drive

- Designed high tensile loads

- Optimised for oil and gas drilling applications

Visit the shop

CFSPECIAL.572 Motor cable

- Motor cables for top drive

- Designed high tensile loads

- Optimised for oil and gas drilling applications

Visit the shop

CFSPECIAL.592 Hybrid cable

- Hybrid cables for top drive

- Designed high tensile loads

- Optimised for oil and gas drilling applications

Visit the shop

Visit the cable overview

- Still unsure on which cable works best for your application? Use the cable configurator or alternatively you can visit the chainflex overview

Visit the cable overview

Free white paper

More automation in the maritime sector

What challenges, what advantages do automotion and digitalisation bring to the maritime industry? How can companies meet the strict test criteria to have components certified by competent instituations such as DNV? What opportunities arise for suppliers, plant manufacturers and operators of drilling platforms and ships through the use of certified components such as cables?Download free here

Cable guidance under adverse conditions

Originally developed for a very sprecific application in deep drilling rigs, the e-loop energy supply system is also used in bucket wheel excavators, ship unloaders and in the construction of offshore wind turbines in just a short time after its market launch. In this white paper you will find various cases as a source of ideas.Download free here

Energy chain options for offshore and marine

E4.1 series

The energy chain designed for

virtually all applications

- Tough

- Modular system

- High stability

E4 overview

E4.350 energy chain

The worlds largest polymer energy chain

- Extremely strong

- Noise reducing

- High push/oull strength

E4.350 example in drilling vessel

e-loop

The igus® alternative to the service loop

- High strength pull rope

- Ideal for 3 dimensional applications

- Perfect for drilling rigs

More information on the e-loop