Robust energy supply systems and cables for heavy-duty offshore cranes

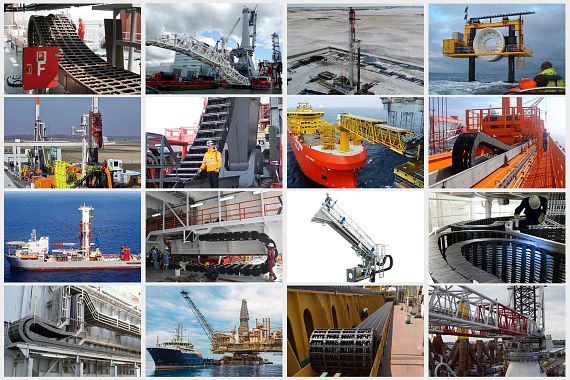

For rotary cranes and gantry cranes on ships and offshore installations, we offer energy supply systems, cables, and trough systems that can also be designed as a complete system ready for connection. The E4.1 series plastic energy chains or heavy-duty roller energy chains are used on riser gantry cranes, which exceed festoon systems and steel energy chains primarily because of their corrosion-free operation and cable-friendly interior separation. A cable-friendly friction pair between the energy chain and the cable results in a greatly extended service life for the cables and the system.

For rotary cranes, an RBR rotating energy supply can be used instead of the usual slip rings. This solution provides modularity and freedom from maintenance. The rotary module features downtimes and maintenance intervals for the entire system that are up to 90% better than those of festooning systems and slip rings.

For rotary cranes, an RBR rotating energy supply can be used instead of the usual slip rings. This solution provides modularity and freedom from maintenance. The rotary module features downtimes and maintenance intervals for the entire system that are up to 90% better than those of festooning systems and slip rings.

Wind farm installation cranes (LEC)

Rotating energy supply systems and cables, including accessories for leg encircling cranes (LECs): This heavy-duty rotary crane from Liebherr features an energy chain that allows a rotating range of 900°.

Read the user report

Gantry crane

For this gantry crane on a drilling vessel, a complete energy supply system consisting of plastic energy chains, guide trough and chainflex cables was implemented.

Read the user report

Sheerleg cranes

Heavy cable weights and long travels. "Heavy duty" energy chains for high additional loads provide high planning reliability for cable guidance on two sheerleg cranes.

Read the user report

Knuckle boom cranes

In the platform of this knuckle-boom crane on a pipe-laying vessel, a rotary module with a compactly laid energy supply system was implemented. It safely guides the data and signal cables and hydraulic lines.

Read the user report

Our products for offshore cranes

- Rotation systems with up to 900° rotation

- Easy integration into the customer's structure

- Extended system guarantee available

RBR rotating energy supply

- Robust and up to 70% lighter than steel

- Special interior separation system prevents parts from falling out

- Modular design

E4.1 series energy chain

Offshore crane success stories

In the heavy lifting sector, cable guidance requirements for gantry, rotating, LEC, knuckle boom, and sheerleg cranes are often similar. With systems usually involving long travels and high cable weights, highly stable solutions are required that ensure high planning reliability under aggressive environmental conditions at sea. Find out more about how our motion plastics products are used in platforms or on crane girders here.

Discover the success stories here