User report

Flexible and durable: 3D e-chain for Schütte CNC multi-spindle automatic lathes

Compact design with high flexibility: triflex energy chain with more than 4.5 million cycles per year

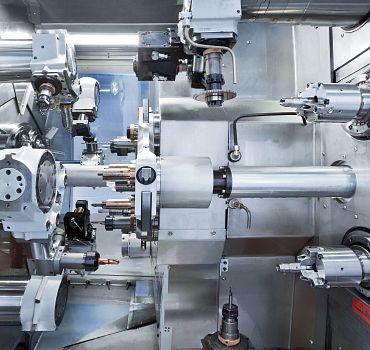

Schütte CNC automatic lathes are known worldwide for very high productivity and – a key feature – flexibility. With up to nine spindles, they allow many machining processes in one clamping procedure. Each spindle must be supplied with energy, signals, and coolant. For this task, Schütte uses triflex R 3D energy chains from the SCX series.Profile

- What was needed: triflex R type TRL 60 3D energy chain

- Requirements: To supply the spindles, the cable guide needed to perform very rapid rotational movement in addition to the axial feed. It had to reliably handle more than 4.5 million such cycles per year.

- Industry: machine tools

- Success for the customer: high-tensile-strength energy supply system with easy filling. Compact design for compact machine construction with more space for the cables. High flexibility thanks to precisely manufactured ball-and-socket-joint connection without a steel cable. Long service life for extremely heavy duty applications.

Discover all products for machine tools

Problem

Manufacturers of complex turned parts want to carry out as many machining processes as possible in one assembly in order to save time and money. The best way to achieve this goal is with the SCX series from Schütte (Picture 1). Even in the basic version, the multi-spindle automatic lathes offer six main spindles and a counter spindle for workpieces that can be produced almost entirely from the first side of the workpiece. For applications where the second side of the workpiece also has to be extensively machined, the concept can be extended to up to nine spindles (Picture 2). And since the spindles can also work in the C and Y axes, SCX automatic lathe users enjoy completely new freedom for processing complex workpieces. The basic design features of the SCX series include the elimination of everything not directly involved in workpiece creation: drive and guide elements, lubrication and cooling lines, and electrical cables. But each spindle must of course be supplied with cooling medium, hydraulic oil, energy, and signals. And high demands are placed on this media, energy, and signal supply: In addition to the axial feed, a very rapid rotational movement must also be performed. The application places extreme demands on energy chain service life: The typical cycle times of five to ten seconds mean 5,760 cycles – and a corresponding number of energy chain movements. This means that the first 100,000 cycles are completed after just 17.3 shifts. One year of 24-hour, five-day operations is more than 4.5 million cycles. And Schütte is by no means satisfied with a service life of one year for a component - its machines are known worldwide for their long service life.Solution

From the outset, the plan was for an energy chain to supply energy to the spindles. But the originally selected model did not meet Schütte's high standards. During the production of the first series, for example, the staff told the design manager that the energy chains were difficult to fill.Schütte then looked for an alternative. And found it in our triflex R 3D energy chain (Pictures 3 and 4), originally designed for demanding six-axis robotic applications in harsh industrial environments - that is, for axial and rotational movements in a chain.

Despite its high tensile strength, the three-part 3D chain is very easy to fill – to the centimetre. Even the lines for such media as coolant, which have a fairly large cross section, could therefore be clipped into the chain without much effort.

The new e-chain therefore quickly won over Schütte's production staff. And the designers appreciate the compact design, which is important given the limited space available in the machine. The triflex R offers more space for cables than the previous model, and since it requires no steel cable thanks to the precisely manufactured ball-and-socket joint connection, it is also extremely flexible.

The energy chain is designed from the ground up for a very long service life, even under extremely heavy loads. Tests and practical applications have thus far shown that the energy chains can withstand these loads – even though they have to travel long distances at high speed with every tool cycle and carry out extensive vertical strokes and pivoting movements. Even the oil mists from coolants, many of which are aggressive, do not shorten the chain's service life.

Specifically, the SCX series uses the triflex R-TRL 60, where the L stands for "light" and the number indicates the inner diameter (60mm). The basic triflex R version was not needed because the drive compartment is kept free from chips.