Technical data:

- What was needed: Optimally simulated birth process using the SIMone birth simulator from 3B Scientific GmbH

- Requirements: Corrosion-free, lubrication-free and maintenance-free, contamination by lubricants possible

- Products used: dryspin trapezoidal lead screw made of stainless steel, special design lead screw nut, drylin linear axes, individual worm wheel

- Success for the customer: Head of Development, Swen Dressel: "The birth simulator is used in clean environments such as lecture halls and teaching hospitals. Lubricated drive elements are not common or desirable, especially since they can lead to the contamination of clothing during the essential cleaning of the simulator."

Make a contact request

Mechatronics for the training of obstetricians

With the birth simulator SIMone, 3B Scientific GmbH has an important tool in its product range for the training of gynaecologists and midwives. The mechatronic features are complex: force, moments, direction and path the obstetrician uses to help the plastic foetus out of the womb are accurately recorded. Maintenance-free and lubrication-free linear bearings and lead screws from igus make a contribution to the optimally simulated birth process.The birth process is recorded with force feedback sensors

The birth is imminent. The contractions are irregular, the mother's blood pressure rises dangerously. Various scenarios are now possible: medication, caesarean section, surgery with forceps or suction cup ... An experienced gynaecologist or a well-trained midwife makes the right decisions in such a situation. But how does a medical student learn what to do when training to become a specialist?

The answer is provided by 3B Scientific GmbH with the birth simulator "SIMone". The user of the simulator helps a plastic foetus to be delivered in different scenarios each requiring specific procedures. The actual birth process is both recorded and predefined with the aid of a force feedback system: the foetus moves through the birth canal. The integrated force-moment sensor, measures the forces and the directions with which the obstetrician brings the baby into the world, and displays on the screen, in real time, these actual values in comparison with the set points regarded as optimal, in addition to medical data such as blood pressure. The mother's breathing sounds and expressions of pain are just as audible as the sounds of the child's heart. The effects of medications such as paracetamol or drips are also simulated and the position of the child in the pelvis is displayed in 3D on the screen.

It is a fascinating process for the layman, but highly instructive for the obstetrician. 3B Scientific GmbH has a real innovation in the product range and a great service for expectant mothers as well as obstetrics in general. One example of many: SIMone is standard equipment in midwifery training in Cuba, and the Cuban Ministry of Health mentions use of the simulator as one of the reasons for the country's extremely low birth mortality.

It is a fascinating process for the layman, but highly instructive for the obstetrician. 3B Scientific GmbH has a real innovation in the product range and a great service for expectant mothers as well as obstetrics in general. One example of many: SIMone is standard equipment in midwifery training in Cuba, and the Cuban Ministry of Health mentions use of the simulator as one of the reasons for the country's extremely low birth mortality.

drylin linear bearing instead of recirculating ball bearing guides

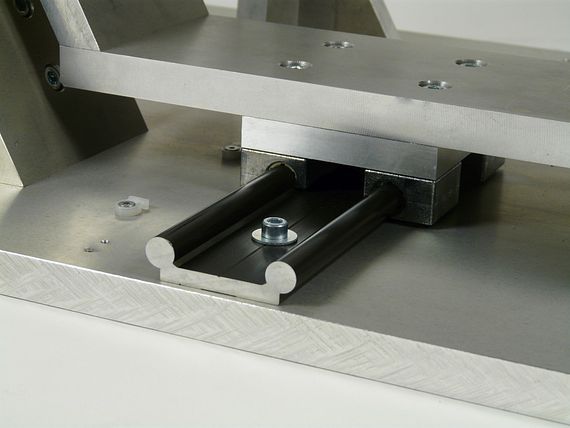

Optimisation work was needed on the mechanical side - especially on the linear axis, which provides the path through the birth canal. Swen Dressel, Head of Research & Development: "A recirculating ball bearing guide was provided here, but it had to be cleaned regularly because the lubricant needed to simulate the birth process dripped into the unit. If it is not removed from there, the unit will corrode." Since the users did not always pay attention to the appropriate maintenance instructions, it sometimes led to failures.Therefore, the developers looked for an alternative - and found it with the drylin system from igus. These linear axes use a sliding pair of hard-anodised guide rails and liners made of the wear-resistant high-performance plastic iglidur with incorporated lubricant. So they work without lubrication, and their function is not impaired by contamination through lubricants.

More drive elements were substituted

This solution now proves itself to the full satisfaction of the developers – and led to the replacement of other components by igus bearings. Swen Dressel: "For the translatory positioning of the foetus, we now use a drive rod consisting of an igus lead screw and a backlash lead screw nut."The dryspin lead screw technology is based on the principle of lubrication-free and maintenance-free linear technology. The specifications and geometries of our lead screw technology, which are matched to the polymer nut and lead screw, guarantee efficiencies of up to 82% and a service life that is up to 30% longer than conventional lead screw drives.

The worm wheel on the force feedback sensor, which causes the foetus to rotate and was originally made of brass, has also been replaced. "We had to do a lot of work on this component. We now buy an igus ready-to-install drawing part made of iglidur, which has proven itself very well."

Conclusion: Freedom from maintenance and cost savings

As a result, the entire birth simulator is now maintenance-free. This brings advantages for the manufacturer and the users, who also benefit from the fact that the moving components no longer need to be greased. Swen Dressel: "The birth simulator is used in clean environments such as lecture halls and teaching hospitals. Lubricated drive elements are not common or desirable, especially since they can lead to the contamination of clothing during the essential cleaning of the simulator."Do you have questions about drylin® lead screw technology?

Our expert, Thorben Hendricks, will answer all your questions about drylin® lead screw technology. Just fill out the contact form, and we will address your concerns. We look forward to your message!► Online contact request

► Make an appointment

► Specialist support by telephone or video chat function

► Order a free sample

Request expert support here

More hygiene in the medical industry due to lubrication-free dryspin® lead screw drives?

No problem - all advantages at a glance

In medical technology, metallic lead screw nuts continue to be the norm. However, they mostly require frequent maintenance and lubrication. In this process, dust and dirt particles can easily stick to the used lubrication. This leads to considerable contamination and a significantly higher wear compared to a system that works in dry operation. Furthermore, the metallic lead screw nuts can corrode quickly in humid environments.To the overview page