Clever solution for dumpers exposed to heavy loads

If there is one construction vehicle that deserves to be called multi-talented, it is without a doubt AUSA's DR601AHG. This dump truck - also known as a dumper in English - can take a load of up to 6 tons.Whether sand or gravel, salt or unit loads such as wood and stone - created for rough terrain, the dumper must do one thing above all: run. Currently, the Spanish company delivers to Europe, Great Britain, China and the US, among others.

Profile

- What was needed: control cable, bus cable, three-dimensional movable energy chain

- Requirements: three-dimensional movable energy chain with twistable cables

- Industry: automotive sector/construction site vehicles

- Success for the customer: designing a rigid driver's seat into one that can be swivelled around by 180°

Problem

AUSA turned to us because their engineers were looking for a technical solution to technically modify the rigid driver's seat into a model that could swivel around by 180°.Solution

The idea: to make manoeuvring the agile equipment even safer for people and materials. Even in rough and very demanding terrain. As a company concentrated on the development and construction of all-terrain industrial vehicles, such as dumpers, forklifts and telescopic loaders, AUSA's focus on work like this made a technical evolution towards greater safety a logical step, given the innovative new technologies that were being developed.Together with AUSA, we developed a solution for the electrical system that made it possible to turn and control the driver's seat even in continuous operation. The most important aspect: reliable operation over a long service life.Our clear recommendation: the use of cables that allow a twist of 180° and are also technically designed for a long service life.

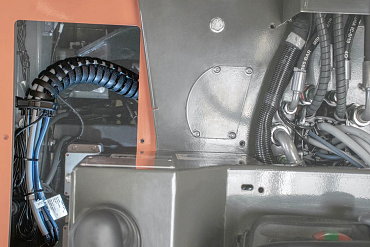

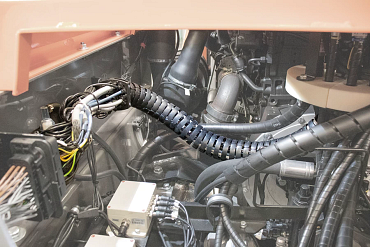

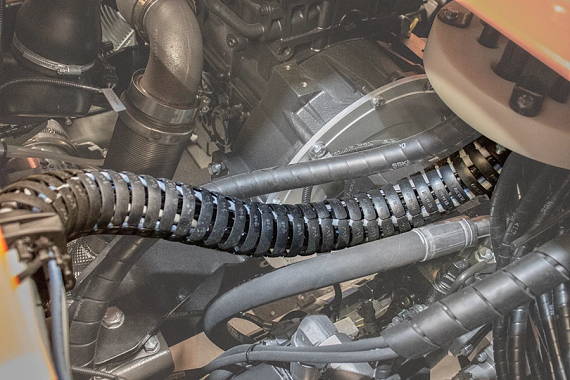

We tested a three-dimensional movable energy chain triflex® R in combination with the CFROBOT8 bus cable and the control cable CF77.UL.D.

The triflex® R proved to be the best option, as it is specifically designed for 3D applications such as rotary and swivel movements. Originally developed for demanding multi-axis robots, it is characterised by high tensile force absorption. It is also very flexible, and does exactly what AUSA needed over a very long period of time, fixed bend radius included.

Thanks to the use of the bus cables, all problems with regard to the torsional movements could be anticipated. By combining soft and sliding construction elements with the included filler elements, it is possible to absorb the forces that occur at the driver's seat of the AUSA dumper. This is due to the PTFE elements and rayon threads. chainflex robot cables contain PTFE liners so that the torsion-optimised shield assemblies can carry out necessary compensatory movements. In addition, bus cables like the one used here have been specially developed and tested for continuously moving e-chain® applications.

The triflex® R proved to be the best option, as it is specifically designed for 3D applications such as rotary and swivel movements. Originally developed for demanding multi-axis robots, it is characterised by high tensile force absorption. It is also very flexible, and does exactly what AUSA needed over a very long period of time, fixed bend radius included.

Thanks to the use of the bus cables, all problems with regard to the torsional movements could be anticipated. By combining soft and sliding construction elements with the included filler elements, it is possible to absorb the forces that occur at the driver's seat of the AUSA dumper. This is due to the PTFE elements and rayon threads. chainflex robot cables contain PTFE liners so that the torsion-optimised shield assemblies can carry out necessary compensatory movements. In addition, bus cables like the one used here have been specially developed and tested for continuously moving e-chain® applications.

This makes them ideal for AUSA and their idea of using them to rotate the driver's seat, not least because the mechanical requirements for the bus cables can be defined specifically for the application by means of the outer jacket material and the design principle: it is designed in such a way that the electrical properties of the respective bus specification can be guaranteed. All in all, it is the precise matching of electronics, connection mechanics and cable to the system to be supplied and the required data transmission rates that have made this cable the perfect solution for AUSA.By incorporating robot cables, AUSA is now equipping its dumpers ideally for three-dimensional movements. Torsion-optimised insulating materials and mechanical damping elements ensure the best transmission properties over the entire service life. AUSA also opted for the cables from igus® because the company can guarantee a rate of five million movement cycles at a torsion of ±180° per metre.

The chainflex® control cable CF77.UL.D installed in the dumper is designed for an enormously high load - both linear and in torsion. The company igus® guarantees a considerable 10 million cycles for the operation of the CF77.UL.D. The cable is oil-resistant without any restrictions. This is not relevant for this sort of AUSA dumper, but it proves once again the load capacity of this cable type. The same applies to solar radiation. It is irrelevant for the driver's seat application, but it emphasises the long service life. In any case, AUSA benefits from a cable jacket made of a halogen-free PUR-based compound that is also low in adhesion and highly abrasion-resistant. This means that the continuous movement of the driver's seat in the dumper can now take place reliably over a long period of time. This also applies to sectors with adverse environmental parameters, such as civil engineering, road construction or transportation, and in view of the different climatic conditions in all 90 countries in which AUSA operates.