xiros® ball transfer units

Move heavy and sensitive loads easily: whether in conveyor technology, the food and glass industry or even in the sports sector. The transport of sensitive or heavy goods can be achieved with ball transfer units without great effort. Loads with a capacity of up to 1,470N can be carried without any problems, so that even heavy goods can be moved in almost all directions. The conveyor ball inside the housing is mounted with many small balls in order to ensure perfect running values. From pure plastic solutions to ball transfer units with a conveyor ball made of stainless steel: optimise work processes with our lubrication-free and low-maintenance ball transfer units for a wide range of applications.

Would you like more information about the xiros® plastic ball bearing range? Our experts will be happy to get in touch with you.

Would you like more information about the xiros® plastic ball bearing range? Our experts will be happy to get in touch with you.

Contact an expert

xiros® ball transfer unit options

Ball transfer units for maximum smooth running

- Ball Ø: 5, 8, 12, 15, 22mm

- All-rounder for sensitive goods

- Housing material: xirodur B180

- Ball material: POM + POM (in the housing)

- Available in UK stock

Visit the shop

Ball transfer units for higher loads up to 1,000N

- Ball Ø: 5, 15, 22, 30mm

- Suitable for overhead installation and lateral guidance

- Housing material: xirodur B180

- Ball material: POM + stainless steel (in housing)

Visit the shop

Ball transfer units: smooth with heavy loads

- Ball Ø: 15, 22mm

- Up to 45% lower rolling friction than BB-515B/522B-B180-POM

- Housing material: xirodur B180

- Ball material: POM + stainless steel (in housing)

Visit the shop

Ball transfer units for higher loads up to 500N

- Ball Ø: 15, 22mm

- Suitable for overhead installation

- Housing material: xirodur B180

- Ball material: stainless steel + stainless steel (in housing)

Visit the shop

Sliding ball transfer units for high impact loads

- Ball Ø: 15, 22mm

- High load capacity with low friction

- Housing material: iglidur J3B

- Ball material: Stainless steel

Visit the shop

Electrostatically dissipative ball transfer unit

- Ball Ø: 15mm

- Ideal for semiconductors and electronic components

- Housing material: xirodur F182

Visit the shop

All other types

- Plastic self-aligning ball transfer units in installation sizes 515 and 522

- Accessories for ball transfer units (clamping rings)

To other types

What are the advantages of ball transfer units?

Transport heavy loads from A to B Roller ball tables make this possible; whether conveyed goods in the form of food, airport goods or glass. Ball transfer units in the conveyor tables make it easy to roll sensitive goods in various directions.Compared to metallic solutions with solid steel housings or aluminium versions with steel balls, ball transfer units from igus are 100% lubrication-free. In addition, the plastic ball transfer units can be used in any installation position, both horizontally, vertically and overhead. Thanks to its technical properties, the xirodur material used is particularly abrasion-resistant, durable and electrically insulating.

In the case of a magnetic environment of an application, customers can assemble the ball transfer units in such a way that glass balls inside the housing provide a completely metal-free solution. Move sharp-edged heavy loads and sensitive goods on roller conveyors or ball tables: xiros ball transfer units are ideal for the safe transport of loads.

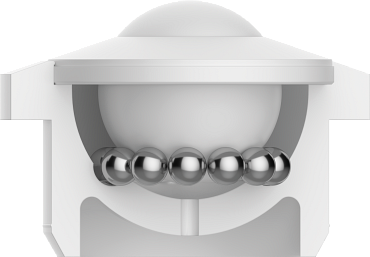

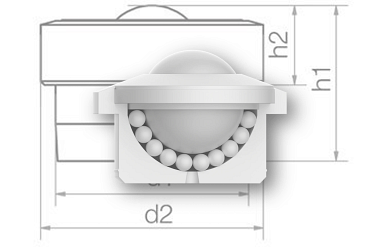

How are the ball transfer units constructed?

xiros® ball transfer units have a housing made of high-performance plastics with an embedded ball socket. This pan serves as a running surface for the support balls. If the load ball rotates, the support balls roll on the ball socket. Depending on the application, various materials are available for the running ball and the support balls. The situation is completely different with the sliding ball transfer unit. The support balls previously used in our ball transfer units are replaced by a sliding insert made of the in-house iglidur® J3B. The stainless steel load ball therefore no longer runs on the support balls as in previous versions, but on the particularly wear-resistant sliding insert.

Ball transfer units are important components in conveyor technology that enable the flexible and low-friction movement of goods on conveyor systems. They consist of a running ball embedded in a housing with additional balls and allow movement in all directions. Thanks to their design, they can be used in various industrial applications, for example in logistics, mechanical engineering and production automation. Ball transfer units of this type help make transport processes faster and more cost-efficient. They are available in various sizes and materials to meet different requirements and bear a variety of loads. Loads of up to 1,470N can be picked up without any problems, meaning that even heavy goods can be moved effortlessly.

Browse the online shop now

Advantages and disadvantages of ball transfer units

The advantages are manifold. They are low-maintenance, durable and can be used in various environments. They play a major role in automation technology as they help improve production processes by optimising the material flow.Benefits

- Facilitating the transport of heavy loads on smooth surfaces

- Easy movement in all directions, which improves manoeuvrability

- Installation is straightforward and does not require sophisticated tools

- Available in various sizes and materials to meet different industry requirements

- Extremely durable, requiring replacement very rarely if properly maintained, which is easy on customers' wallet

Disadvantages

- Relatively unstable on uneven surfaces; can make loads uncontrollable

- Not suitable for very high loads as the pressure on individual balls can lead to damage

- Can generate noise during prolonged use, which can be disturbing in quiet environments

- Small particles such as dirt or chips can restrict the balls' movement

- Less effective at high speeds; precision of movement can be impaired

What are the advantages of ball transfer units from igus?

Compared to metallic solutions with steel housings or aluminium types with steel balls, our igus solutions have the following advantages:✔️ 100% lubrication-free

✔️ Low-maintenance

✔️ Corrosion-free

✔️ Can be used in any installation position, e.g. horizontally, vertically or overhead

✔️ Made from our in-house material xirodur, which is particularly abrasion-resistant, durable and even electrically insulating upon request thanks to its technical specifications.

Application areas of ball transfer units

They are used in a wide range of industries and make it easier to move loads on flat surfaces. In the manufacturing industry, they are often used to transport heavy workpieces on assembly tables or in conveyor systems. They are also indispensable in the logistics sector as they simplify the transfer of goods to storage and sorting areas. Another area of application is mechanical engineering, where the ball transfer units are integrated into machine tables or packaging machines. They are also used not only in industry, but also in public facilities such as airports or shopping centres to make luggage or shopping carts easier to manoeuvre.Selection criteria

When selecting ball transfer units, it is important to consider several factors so as to ensure proper function in your application. Firstly, the load capacity of the ball transfer units should fulfil your requirements. Pay attention to the pressure load limits as well as hole and height tolerances. Other important parameters:- Choice of materials: depending on the application and requirement profile, there are solid-plastic solutions and hybrid solutions made of plastic and stainless steel

- Surface finish: depending on the transported goods, the surface has to be smooth or slip-resistant. The size and shape of the profiles should be suitable for your application to ensure a smooth operation.

- Installation environment: check the available dimensions of the installation space and the mounting options for correct installation. Clamping rings are available as accessories in the online shop.

Installation and maintenance

Ball transfer units are always an effective solution when it comes to moving heavy loads with minimum effort. During installation, it is important to take the load capacity limits into account to avoid overloading.Make sure that the mounting surface is even and clean for optimum function. The maintenance of ball transfer units is also essential to ensure their longevity. Regular inspections help recognise wear and tear or damage at an early stage. There is no need for lubrication as our plastic solutions do not require grease. This extends maintenance intervals.

Also bear in mind in which environmental conditions ball transfer units are used. Extreme temperatures or chemicals may require special materials or protective measures so that they can maintain full functionality.

Where can I buy the plastic ball transfer units?

You can buy our plastic solutions in our online shop. There you will find different versions for the following requirements, among others:

- Extremely smooth running

- Suitable for high loads

- Sliding for high impact loads

- Ball transfer unit with disc spring for high impact loads

- Self-aligning

▷ Buy ball transfer units in the online shop