Electrostatically discharging 3D printed components

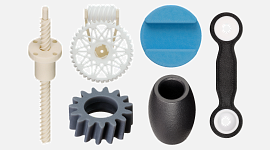

iglidur® i8-ESD is an electrostatically dissipative SLS material for long-lasting, abrasion-resistant 3D printing components. It is ideal for applications where ESD specifications are essential for avoiding damage to electronic components and manufacturing anti-static parts for machines that require ATEX certification.

New product: iglidur® i9-ESD has a lower conductivity than iglidur i8-ESD, which prevents unwanted discharge currents between sensitive electrical components. This makes it particularly suitable for electronic connectors.

In addition to its antistatic specifications, iglidur i8-ESD and i9-ESD are also characterised by their outstanding rigidity, as a result of which the parts are deformed to a lesser degree than other materials under the same load.

New product: iglidur® i9-ESD has a lower conductivity than iglidur i8-ESD, which prevents unwanted discharge currents between sensitive electrical components. This makes it particularly suitable for electronic connectors.

In addition to its antistatic specifications, iglidur i8-ESD and i9-ESD are also characterised by their outstanding rigidity, as a result of which the parts are deformed to a lesser degree than other materials under the same load.

Visit the shop

Upload your CAD model now and get a price right away

Upload doesn't work? Click here to start the upload directly in the 3D printing service tool.

iglidur i8-ESD

- Contact resistance 104 to 107ohms x cm

- SLS powder can be processed on all regular SLS systems

- Available in 2kg containers for processing on low-cost systems with and without CO2 lasers

- Manufacturing time of components in the 3D printing service: 7-10 days

More about iglidur i8-ESD in the material shop

New: iglidur i9-ESD

- Contact resistance 106 to 109ohms x cm

- Medium conductivity for the production of highly sensitive electronic components

- SLS powder can be processed on all regular SLS systems

- Manufacturing time of components in the 3D printing service: 7-10 days

More about iglidur i9-ESD in the material shop

Free sample component

Order a 3D-printed sample gripper made of iglidur i8-ESD free of charge and take a look at the SLS material.Order a free sample

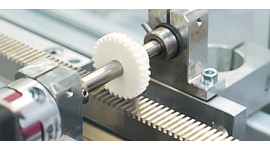

Service life calculator

Simply enter the application parameters to determine the expected service life for ESD gears printed in 3D.To the gear service life calculator

Tech up

- Electrostatically dissipative (ESD)

- Contact resistance:

iglidur i8-ESD 104 to 107ohms x cm

iglidur i9-ESD 106 to 109 ohms x cm - Excellent service life - for example, a pivoting abrasion resistance factor of 2 to PA12

- Can be processed on regular laser sintering systems

- Suitable for explosion risk areas and ATEX certification

- Reworking, grinding and

chemical smoothing with the online 3D printing service - Lubrication and maintenance-free

Cost down

- No minimum order quantity, no

tool costs - No machine failure: predictable gear service life

- Delivery time: three days outbound

- Component entirely black, no additional dyeing necessary

- Compare prices online immediately

Proof

- ESD properties are essential, particularly in the electronics industry, for avoiding damage to electronic components

- Also interesting for all other industries in which avoiding electrostatic charges is important

- 3D printing put to the test

- ESD specification test report

Sustainability

- No lubrication necessary

- Can be recycled

- 3D printing: low material requirements, since there is no waste or sprue

Tested! iglidur® I8-ESD wear test

Pivot wear 2MPa 0.01m/s

Vertical axis: wear rate [µm/km]

Linear wear: 1 Mpa 0.1m/s stroke 5mm

Vertical axis: wear rate [µm/km]Further wear-resistant ESD components from igus

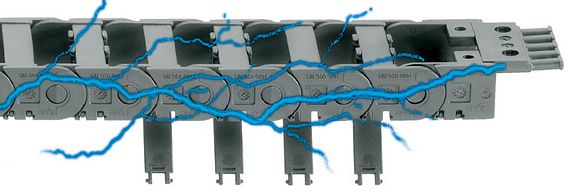

ESD energy chains

Energy chains made of the conductive ESD material igumid ESD have been specially developed for the avoidance of static charging in processes involved in the manufacture of electronic components or modules. The ESD energy chains have been certified according to DIN 53482 as well as to the guidelines relating to static electricity ZH1/200 of the German Federation of the Statutory Accident Insurance Institutions for the Industrial Sector (Hauptverband der gewerblichen Berufsgenossenschaften) and have been tested with more than 10 million cycles, which makes them suitable for the highest requirements. The openable energy chains with mounting brackets and interior separation are available from stock.

ESD

ESD ball transfer units

The xiros polymer ball transfer units made of xirodur F182 are ideal for roller conveyor guides and the transport of goods that have sharp edges or are sensitive. Uncontrolled discharging is a thing of the past for transport goods and customers. These components make it possible to smoothly move loads of up to 500N in all directions. In addition, the polymer ball transfer unit can be used in any installation position, vertical, horizontal and overhead.

Antistatic bar stock

The lubrication-free iglidur bar stock offers the option of freely designing any type of maintenance-free sliding elements and bearings. In addition to bar stock for in house processing, plain bearings and sliding elements can be ordered in the CNC service. For urgent prototypes, components can be manufactured within a few days in line with an agreed deadline.

Antistatic bar stock in the shop

ESD plain bearings

With or without flange, the plain bearings made of iglidur F2 help to avoid electrostatic charging. Good resistance to media and temperature, suitable even in wet conditions due to low moisture absorption and good universal coefficient of wear, pave the way for a wide range of applications.

ESD plain bearings

Further ESD components

igus supplies a wide range of wear-resistant components made of antistatic polymers, which, thanks to the incorporated solid lubricants and their special composition, have an especially long service life and considerably reduce the amount of maintenance work needed.

Find out more about our ESD products and materials

More information about igus® 3D printing

News

Discover our new products and service tools for additive manufacturing!

Go to the innovations!

Tested!

3D printing materials made of iglidur compared to PLA, ABS and other materials and manufacturing processes.3D printing service

Customised, additively manufactured components with the online 3D printing service in just a few steps.To the igus® 3D printing service

3D printing materials

Discover our other abrasion-resistant plastics for industrial use.More 3D printing materials