- Up to 21 times longer service life compared to the previous endurance runner xirodur B180 due to iglidur® J3 cage

- Application temperature: -40 °C to +80 °C

- Ring material: xirodur® B180

- Cage material: iglidur® J3

- Ball material: Glass

xiros® deep groove ball bearing xirodur® B180, up to 21x longer service life, glass balls

xirodur® B180 | The all-rounder with J3 cage

High speeds lead to high centrifugal forces of the balls in the bearing. This accelerates the balls outwards. The cage material requires a certain stability, cage pockets would otherwise expand, giving the balls more clearance and freedom of movement . If the balls can no longer maintain the correct position, there is more wear and the bearing fails sooner than expected. In addition to reinforcing materials, which increase the strength of the cage material, sliding friction occurs between the balls and the cage. Solid lubricants improve sliding performance. That is why we use iglidur® materials for cages. They contain additives that improve stability and sliding properties.

Typical application areas:

- Cooling fans

- Fans

- Pumps

![]()

Tech up:

- Service life up to 21x longer than the standard B180 ball bearing all-rounder

![]()

Cost down:

- Longer maintenance intervals

![]()

Proof:

![]()

Sustainability:

- Environmentally friendly, no additional lubricants needed

- igus® supports the circular economy of plastics and is investing in chemical recycling. More at: igus.eu/sustainability

When to use it?

- When I need an economical all-rounder

- If the application temperatures are between -40°C and +80°C

- When the application is underwater

When not to use it?

- If application temperatures are permanently below -40°C or above +80°C ▷ xirodur® A500

- When high chemical resistance is required at temperatures up to +60°C ▷ xirodur® C160

- If antistatic conductivity is required ▷ xirodur® F180

- If the material has to meet USP Class VI and DIN EN ISO 10993 ▷ xirodur® MT180

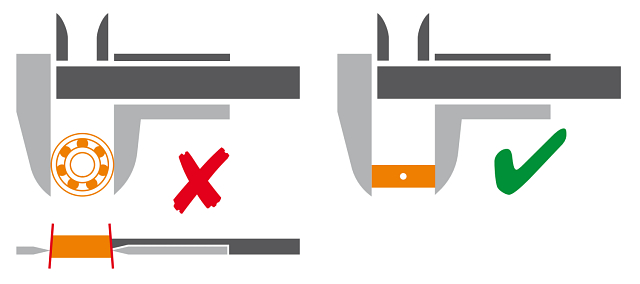

Tolerances and measurement system:

the tolerances for the inner and outer diameter depend on the installation size. These are often approx. ±0.05mm to the nominal size. The bearing rings are usually injection moulded and naturally have a certain ovality. Therefore, the caliper is used to measure 90° to the injection point (if available) over the entire width of the bearing. The dimensions and tolerances are designed in such a way that they fulfil a slight press-fit by hand when using a H7 holder and h6 shaft. An additional locating spigot using a circlip (shaft) and snap ring (housing) is recommended to prevent axial displacement.

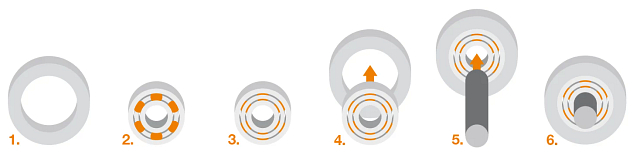

Installation recommendation:

1. Housing (tolerance H7)

2. Front (balls visible)

3. Rear (cage visible)

4. Press-fit the ball bearing, front side first

5. Install shaft (tolerance h6) with chamfer

6. A locating spigot must be provided