Built to last - with drylin W linear guides

Rad9 is THE bicycle shop in eastern Switzerland when it comes to advice, service and high-quality bicycles from well-known brands. The company went in search of suitable assembly stands for their newly erected assembly stations. Although they considered various lifts and assembly stands, none met their specific needs. So they decided to develop a Velolift based on their own specifications. They develop this with our lubrication-free igus products. The MAX Velolift was created with the drylin® W double rail and linear housing.

Profile

What was needed: drylin® W double guides and linear housing

Requirements: The lift should be indestructible, strong and beautiful

and be long lasting

Industry: Bicycle industry

Success for the customer: Lubrication-free, strong and long-lasting function

Do you need more information? Contact us

Problem

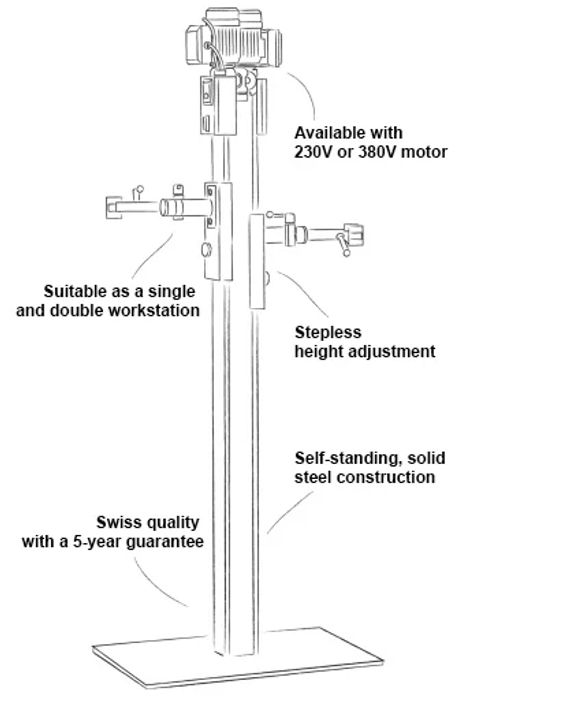

The Rad9 company went in search of new assembly stands for the newly created assembly stations. They looked at different lifts and assembly stands, but none met their needs. For this reason, Rad9 decided to build a Velolift according to their own requirements. The company's idea was to develop a Velolift that is indestructible, strong, beautiful and lasts for a long, long time. The two founders then developed the first "MAX Velolift" together with an employee. The prototype worked well the first time, but the design wasn't quite what Rad9 wanted. The ball bearing used always had some clearance and there was a risk of injuring yourself on the guidance or even getting your hand crushed. The two owners showed their prototype to a mechanical engineer who was a friend of theirs, and he recommended that they replace the H-beam with a square tube and the ball bearing with a lubrication-free linear guide from igus.Solution

Our colleague Axel Ebert from Switzerland visited Rad9 with a bag of samples full of linear solutions. The technical requirements were defined on site, and it quickly became clear to the experienced igus application engineer that the drylin® W modular system was just the thing. Together they decided on the drylin® W double profile guides - two metres long and with a shaft diameter of 20 millimetres, with a guide spacing of 80 millimetres. The ten-millimetre rail would have sufficed, but the price difference was so minimal that the company opted for the more solid version due to its strength, durability and appearance. They also decided on four matching drylin® W linear housings from the modular system. The drylin® W double profile guides are made of hard-anodised aluminium and are therefore corrosion-free. The pillow blocks from the drylin® W linear range are also designed for dry operation and use no lubricants, such as oils or greases. The drylin® W linear product range has many advantages over conventional recirculating ball bearings. No lubrication is necessary, dirt and dust cannot adhere and there is no costly maintenance. MAX Velolift focused on reducing the lift to the essentials. However, this precisely fulfils its function by keeping bicycles permanently strong and safe at the right height.

Axel Ebert, igus Switzerland

"Classic guidance systems have to be lubricated and can get dirty and sticky and later even jam. That doesn't happen with our lubrication-free linear system." - Source: igus GmbH

Adrian Schrepfer, Rad9

"We were immediately enthusiastic about the igus linear guide. The operation is extremely quiet and there is no longer any need for the annoying lubrication." - Source: igus GmbHFurther application pictures