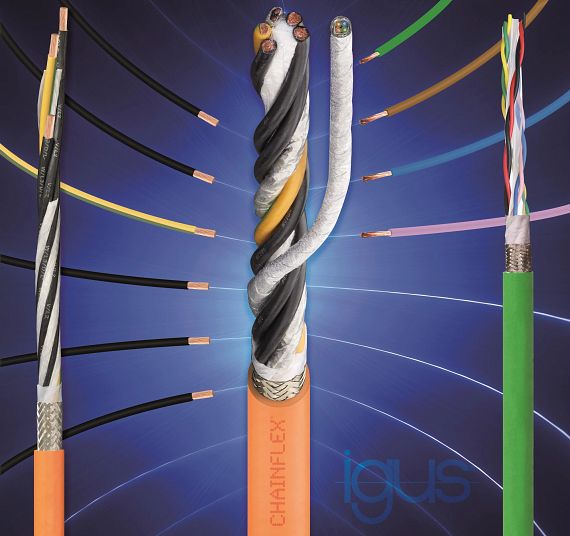

chainflex® cable jacket materials

Information on cable jacket materials.

The outer jacket of a cable provides protection against various adversities such as mechanical stress, temperature or chemical substances with which the cable comes into contact. For chainflex® cables, igus® offers the jacket materials PVC, PUR and TPE. In doing so, igus® ensures that the mixtures of the jacket materials are adapted to the requirements, low in adhesion and highly abrasion-resistant. Depending on the application and external conditions, you can choose between different jacket materials.

The PVC jacket is the most cost-effective jacket material, which, by its nature, is designed for low to moderate loads and is ideal for ambient temperatures of +5°C to +70°C. Like all igus® jacket materials, PVC is a very abrasion-resistant material mixture for use in the energy chain. PUR, on the other hand, is also notch-resistant and offers high oil-resistance, which is ideal for use in machine tools. In addition, there is an extended temperature range of -25°C to +80°C and a high UV resistance. By contrast, the material TPE achieves the highest UV resistance and oil or organic oil resistance. The temperature range is from -35°C to 100°C.

Cable jacket options

PVC or polyvinyl chloride is a very versatile thermoplastic material and is often used on assembly lines as well as in packaging technology or lighting technology due to its chemical structure and the low flammability of the material. Due to their high strength and good insulation properties, PVC cables are popular even for thin insulation. PVC is resistant to constant moisture and also salt water. In the case of fire in a PVC cable, an additive such as chlorine in the jacket material releases halogens, which can pose a danger to humans.In the low voltage range (up to 1,000V) PVC is also known as the material with the best price/performance ratio. igus offers PVC cables made of non-oil resistant and oil-resistant compounds.

PUR or polyurethane, on the other hand, is a halogen-free and self-extinguishing thermoplastic elastomer and has become increasingly important as a cable material in recent years. Up to a certain temperature, PUR is very rubber-like, which makes PUR very interesting for cables, as it is very resistant to bending due to this behaviour. There are the properties of a strong jacket material such as notch strength, low abrasion values and cold flexibility. In addition, its chemical compatibility is better than that of other materials. PUR cables from igus are resistant to oil and coolant and, due to their composition, do not contain any toxic halogens which could be dangerous in case of fire. PUR cables are a popular material for machine tools, in plant construction, in cement plants, in the paint industry and in the automotive industry.

TPE stands for thermoplastic elastomers and is the generic term for numerous subcategories. TPE-U materials are mainly used for flexible cables, since they can withstand mechanical loads very well and are highly resistant to external influences such as chemicals or temperatures. TPE is generally suitable for a temperature range of -35°C to +100°C. In addition TPE is halogen-free. By adding halogen substances, TPE can also be produced as a flame-retardant material and is therefore UL 94-HB compliant. It is often used in energy chains, especially in harsh environmental conditions or applications involving continuous movement. TPE cables are a popular material often used in crane applications, materials handling or low temperature applications..

Are you familiar with our online tools?

Simply find and choose a suitable type, calculate its service life and order it onlineChainflex® product finder

Find the right cable for your application quickly and easilyTo the product finder

Service life calculator tool

Calculate the service life of any chainflex® cableTo the service life calculator

chainflex® wiki

Find everything you need for chainflex® cablesFind out more

Special cables configurator

Configure your individual cable in just three minutesTo the configurator