Savings on cables with the price check

Tech up, cost down. It's our job.

Tech up, cost down. It's our job.

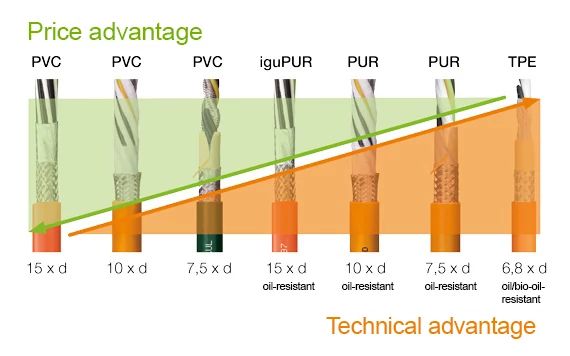

Choose cost-effective PVC instead of PUR

As a jacket material, PUR (polyurethane) has decisive advantages in some areas, but not in all. Our goal is to enable you to objectively decide whether a cable with a PVC jacket is not only sufficient but also perhaps the better solution.Contents:

- Properties and advantages of PUR as the jacket material

- Properties and advantages of PVC as the jacket material

- What savings are conceivable?

Advantages and properties of the two materials

PVC

- Good abrasion resistance

- Highly flame-retardant

- Very easy to harness

PVC or polyvinyl chloride is a versatile plastic mixture. Nevertheless, there is a widespread notion that PVC cables are suited to static installation only.

But that isn't quite right. There are thousands of different PVC mixtures for a large number of different applications, so it is important to find the right one for use in energy chains. For igus chainflex cables, we have selected a mixture that shows great abrasion resistance in e-chains, can be very easily harnessed, and is even cost-effective. That is why PVC cables are often used in industries in which dry environments and room-temperature conditions are common, such as the packaging and wood industries.

PUR

- Good oil resistance

- Durability at low temperatures

A PUR (polyurethane) outer jacket is primarily notable for its very good resistance to oil. PUR cables are often used in industries such as machine tool manufacturing, in which environmental conditions are often dirty and substances such as oil or coolants are common. Still, the jacket remains flexible even in continuous operation in an energy chain and can withstand high mechanical loads. Furthermore, PUR cables are also well-suited for low-temperature applications.

Example of a calculation for catalogue cables

CF210.UL in PVC

Number of cores and conductor nominal cross section: (4G2.5+2(2x1.5)C)C

Max. outer diameter: 14mm

Bend radius: 10xd

Art.: CF210.UL.25.15.02.01.D Price: €6.80/m

VS.

Savings: €2.05/m*

CF270.UL.D in PUR

Number of cores and conductor nominal cross section: (4G2.5+2(2x1.5)C)C

Max. outer diameter: 14mm

Bend radius: 10xd

Art.: CF270.UL.25.15.02.01.D Price: €8.85/m

CF5 in PVC

Number of cores and conductor nominal cross section: 12G1.5

Max. outer diameter: 15mm

Bend radius: 6.8xd

Art.: CF5.15.12.D Price: €4.03/m

VS.

Savings: €3.58/m*

CF77.UL.D in PUR

Number of cores and conductor nominal cross section: 12G1.5

Max. outer diameter: 15mm

Bend radius: 6.8xd

Art.: CF77.UL.15.12.D Price: €7.61/m

CF211 in PVC

Number of cores and conductor nominal cross section: (4x(2x0.25))C

Max. outer diameter: 8mm

Bend radius: 7.5xd

Art.: CF211.02.04.02 Price: €5.89/m

VS.

Savings: €0.23/m*

CF211.PUR in PUR

Number of cores and conductor nominal cross section: (4x(2x0.25))C

Max. outer diameter: 7.5mm

Bend radius: 7.5xd

Art.: CF211.PUR.02.04.02 Price: €6.12/m

* The € prices are based on German list prices and can vary internationally.

Practical chainflex application examples

Today, servo cables are the standard for drive technology in automation and machine construction. The movements which cables are subjected to in these industries are associated with great mechanical stress. Furthermore, cables are often used in environments where moisture, oil, dust or swarf is common. That is why choosing the right jacket material is critical. To ensure constant jacket material quality, our cables are tested time and again under real-world conditions so that a binding guarantee can be granted or the service life calculated online. The cables are tested in both short-term batch tests and long-term service life tests.Example of long-term test 3841a on a CF21 series servo cable (PVC jacket) with a test bend factor of only 6.1xd and 54 million strokes completed.

Test 3841a servo cable CF21.UL

But this choice of jacket quality is available not only for our servo cables, but also for all our other cable types, such as measuring system cables, bus cables, control cables etc. They, too, have been tested in our test laboratory.