Technical data:

- What was needed: A mobile scanning machine that uses air ultrasound to inspect even complex plates and free forms

- Requirements: Absolutely no lubrication or maintenance, many degrees of freedom of movement, low weight, ability to withstand high forces, high precision, compactness, low backlash

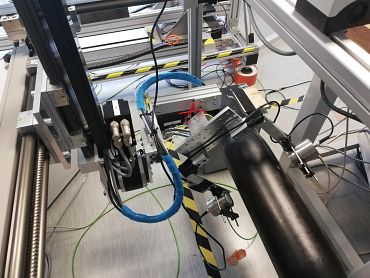

- Products used: drylin® SLW-1660 with an integrated dryspin® high helix lead screw made of stainless steel, robolink® RL-D-20 and RL-D-30 knuckle joint drives, each with stepper motors, encoders, and proximity switches

- Success for the customer: Complex test object shapes require many degrees of freedom of movement. The bearings must be lightweight, but still able to handle great forces and always ensure sufficient precision. That is why the design engineers are using drylin® lead screw linear modules (SLW-1660) with adjustable plain bearing clearance and robolink® D knuckle joint drives (RL-D-20 and RL-D-30) with stepper motors, encoders, and proximity switches. The components are compact and suited to industrial use and allow modular machine design. The engineers say that the drylin® lead screw has amazingly little backlash (too little to be noticed), allowing precise measurements to be carried out.

Do you need more information? Contact us here

Problem

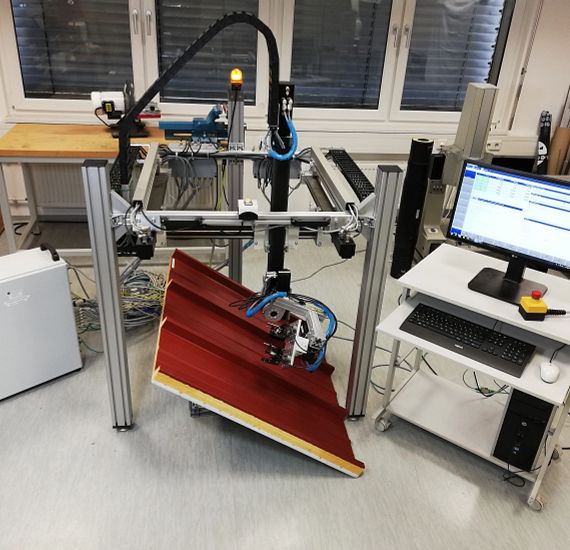

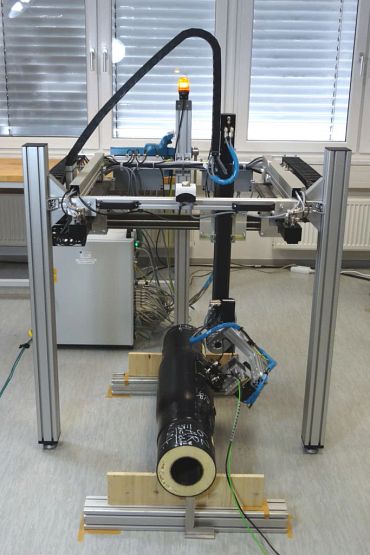

Non-destructive material testing: In order to couple ultrasonic waves into material, conventional ultrasonic testing methods use a couplant. Special equipment technology eliminates the need for a couplant, so not only is testing with so-called air ultrasound contactless, but new materials such as lightweight materials can also be tested.As part of the “IfuS” research project (funded by the German Federal Ministry of Education and Research), a transportable, flexible scanning machine for checking plates and complex free forms with air ultrasound was to be developed. The result was the “PortUScan 460”. With maximum scanning area, the scanner was to be as flexible, small, light, and therefore mobile as possible so that it could scan large or heavy objects outside the laboratory with little effort. For possible applications in industry and outdoors, a certain robustness of parts was required.

Alternative bearing designs based on rolling bearings, recirculating ball screws, or metal worm gears were usually too solidly built and therefore too large and heavy because they were intended for such applications as milling technology. The scanner's weight would have been excessively increased and its range of applications limited.

Solution

Complex test object shapes require many degrees of freedom of movement so that the sonic heads are always guided at the correct distance and angle to the surface. So the bearings must be lightweight, but still able to handle great forces and always ensure sufficient measuring speed and precision. The drives also needed to have as little backlash as possible.Four SLW-1660 linear drives with adjustable plain bearing clearance and dryspin high helix lead screw and two robolink RL-D-20 and RL-D-30 knuckle joint drives, each with stepper motors, encoders, and proximity switches, were used. igus supplied the complete drive assemblies for the scanner. They are compact and suited to industrial use and allow modular machine design, so drives not needed for a given application can be quickly removed. Plastic plain bearings, stainless steel lead screws, and an IP68 motor protection rating ensure that dirt and moisture pose no problems. Adjustable plain bearings guarantee minimal bearing play, and the dryspin lead screws also ensure astonishingly low (undetectable) backlash. This ensures very good measurement precision.

More application pictures and videos

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here