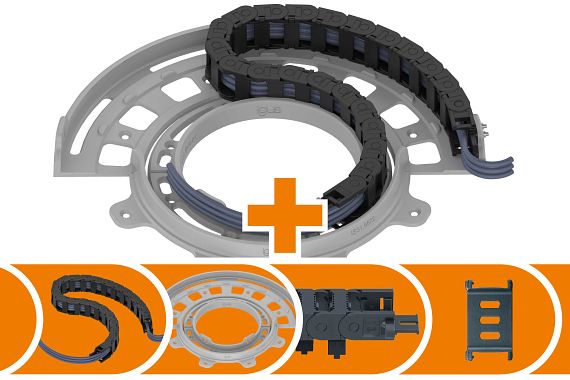

Polymer Rotation Module PRM

Complete system with polymer guide trough, 360° rotation angle

The PRM rotating energy supply system is a plastic trough for small measuring and handling machines, for example. The guide is also suitable for camera applications. It does not require any sliding contacts and is protected against corrosion.

Technical data:

- Maximum angle of rotation: 360°

- Outer diameter: from 200mm to 500mm

Availability:

- e-chains series E2i.10 (PRM200 + PRM300)

- e-chains series E2i.15 (PRM400)

- e-chains series E4.21 (PRM500)

Go to shop for complete sets

Try it out at home or in the office and get a first impression

You can test the Polymer Rotation Module (PRM) with our new, free augmented-reality service. Access the service with your PC and scan the QR code with your smart device for the augmented-reality model or click on the link directly with your smart device.Test the augmented-reality service here

Tech up

- No sliding contacts, all media in a single system

- Complete system can be ordered with only one number; it includes an e-chain and separated guide trough and integrated strain relief

- Weight savings of up to 85% compared to steel guide trough

- Various inner widths with a single guide trough

- Improved guidance, minimised displacement forces

- Protected against corrosion

Cost down

- Up to 70% more cost-effective than a comparable steel guide trough

- No project planning costs

- No minimum purchases – low system price, no minimum order

- Can be delivered pre-assembled - reducing on-site installation costs

Proof

- up to 85% less weight than a comparable steel component: 0.175kg compared with 1.50kg

- Up to 60% lower costs: possible sale price for plastic guide trough: €597 vs. steel: €1,602 (one-to-one comparison)

Sustainability

- Simplified guide trough manufacturing process. Production at only one location

- No need for sheet metal cutting, rolling, welding or galvanising/passivating.

- Can be produced from recycling material

- Have your energy chain processed as part of the igus Chainge recycling program regardless of the manufacturer

- igus supports the plastics circular economy and is investing in chemical recycling

Weight saving

Cost savings

PRM rotating energy supply

Complete sets in the shop

The scope of supply includes suitable e-chain, mounting brackets, separators, strain relief system and guide trough. Discover our new shop offering complete sets of our PRM system.Go to shop for complete sets

You might also be interested in

10 tips for a reliable rotating energy supply

Ten valuable tips for the correct guide trough for circular modules, should you want to design it yourself. Avoid mistakes that reduce the service life of your plant or might even cause downtime.From the contents:

- Plan guide sheets correctly

- Tips on laying cables

- Limit maximum rotation angle

- Generate CAD data for troughs and entire modules

Download 10 tips now free of charge. We would be happy to assist you at any time.

Download design tips now

Application example with Reverse Bend Radius rotating energy supply

Drilling platform robot

High costs, numerous manual procedures and a big safety risk for workers:

a new robot-aided solution compensates for all these negatives associated with work on a drilling platform. An autonomous drilling platform system has been developed for use on land or at sea.

Find out more