Technical data:

- What was needed: A 3D printer that can produce its own essential parts quickly and precisely

- Requirements: High precision and working speed, no vibration, low weight, no lubrication, low friction

- Products used:drylin® linear guides, dryspin® lead screw drives and flange trapezoidal lead screw nuts, stepper motors

- Success for the customer: With the xBot, Benjamin Krux is targeting demanding private users as well as schools, universities, and industry: "The printer is not only fast and precise, but also high-quality and durable. It can process a variety of materials - from compostable PLA to standard ABS to flexible materials such as nylon and rubber-like plastics. The design is solid and all major components are made in Austria or Germany."

3D printing with high precision and speed - and with igus linear guides

Reprap xBot: The printer that makes itself

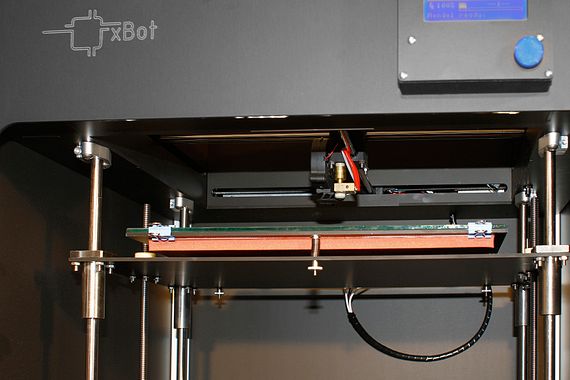

Reprap Austria's xBot is a 3D printer that not only produces essential parts of itself, but also prints precisely and quickly according to the fused deposition modeling (FDM) principle. igus modular drive system components make an important contribution.In the rapidly growing 3D printer market, the Reprap brand has a special reputation. Reprap is not a manufacturer and not a company, but a kind of open-source project or basic construction freely available on the internet to be used by as many people as possible.The idea came from the English professor Adrian Bowyer. In 2006, he developed a 3D printer that can make the plastic parts users need to build the printer themselves: the replicating rapid prototyper or Reprap for short. He published the design data and drawings on the internet. His goal is to have as many users as possible build the 3D printer and also refine it.

This unusual concept has been a success and is continuing to spread. It means that Repraps in different countries use the same basic design, but have quite different characteristics.

xBot from Reprap Austria: fast and highly precise

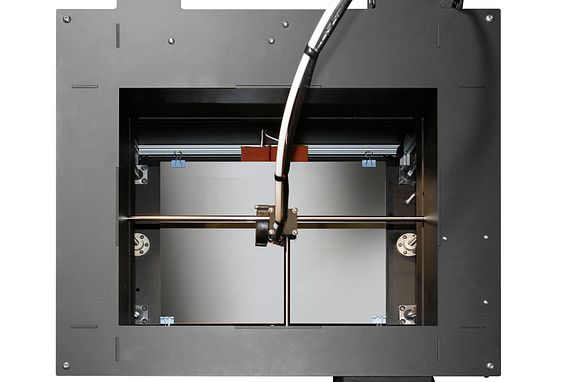

The second generation of the xBot developed by Benjamin Krux/Reprap Austria is impressive thanks to its solid aluminium housing with perfect finish. However, what is impressive is the precision and working speed", the developer explains: "The xBot prints with an accuracy of up to 2/100mm. In practice, a structure consisting of layers 1/10mm thick is usually sufficient. And because we've kept the weight of the moving parts to a minimum, the printer achieves very high speed without vibration."This is due to the low weight of the print head, the high-quality drive technology, and the stable, high-precision print head and print bed guidance. igus linear guides are used in the x- and y-axes, and two parallel lead screw drives from the igus drylin range driven by stepper motors ensure precise print bed positioning in the z-axis.

Drive components from the igus modular system

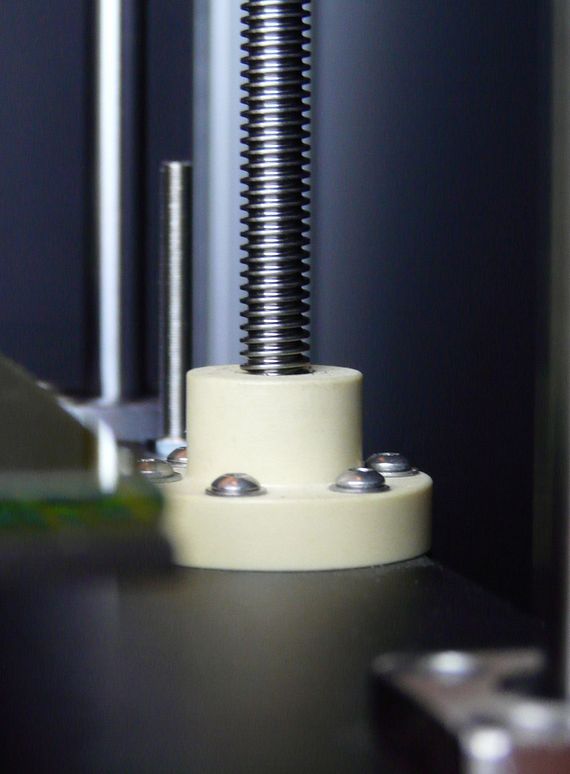

Benjamin Krux selected drylin JFRM flanged trapezoidal lead screw nuts with a 10x2mm trapezoidal lead screw. The trapezoidal lead screw nuts are made of the iglidur J high-performance polymer, which has excellent sliding properties and very low friction thanks to its "built-in" lubricant. This drive concept provides the best conditions for vibration-free, fast travel and precise positioning.Non-driven guides are installed at the four corner points of the print bed, and concealed drive elements from the igus modular system are also used. The vertical guides for the heating bed travel on drylin R linear plain bearings of type RJUM-01, in which a closed anodised aluminium adapter with standard dimensions for recirculating ball bearings is combined with a liner made of iglidur J.

With the xBot, Benjamin Krux is targeting both demanding private users and schools, universities and industry: "The printer is not only fast and precise, but also high-quality and durable. It can process a variety of materials - from compostable PLA to standard ABS to flexible materials such as nylon and rubber-like plastics. The design is solid, and all major components are made in Austria or Germany."

Despite this high quality standard, part of Reprap's self-image is to offer affordable 3D printers ,after all, the idea is for many users to benefit from the advantages of generative manufacturing. This is another reason for Benjamin Krux to use igus components and other cost-effective standard supply parts. Incidentally, he got to know the company almost on site, at the "Automation" trade fair in Linz. Reprap Austria's headquarters is only 30 kilometres away in Neuhofen/Krems.

"3D printers will be used in the same way PCs are today."

Having designed and positioned the xBot as a high-quality and solid-but-cost-effective 3D printer, Benjamin Krux is meeting with lively demand. Currently, for example, he has equipped an "open technology lab" set up by several schools in Vorchdorf/Austria with eight xBots. "In a few years, 3D printers will be used in the same way PCs are today," he says.A relatively new igus business area will then also benefit from the trend: High-performance polymers from the iglidur range are available as filaments that can be processed by 3D printers such as the xBot to make design elements in individual shapes.

Products used

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form, and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here