Pick & place e-chain production - igus

What was needed:

automated application of sealant to metal parts

Requirements:

high flexibility, cost pressure, constant availability

Material:

robolink DC, 7th axis, chain set and suction pad

Industry:

assembly industry

Success for the customer:

all-in-one solution that can be integrated directly into existing operations

automated application of sealant to metal parts

Requirements:

high flexibility, cost pressure, constant availability

Material:

robolink DC, 7th axis, chain set and suction pad

Industry:

assembly industry

Success for the customer:

all-in-one solution that can be integrated directly into existing operations

Go to application

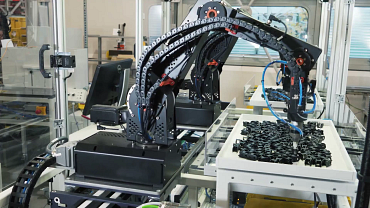

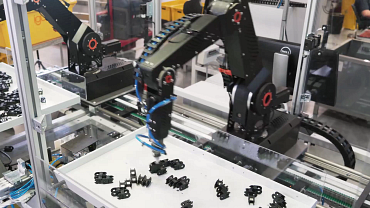

The company igus itself also uses automation solutions in production. In order to meet the high market demand, some energy chains are assembled fully automatically by robots. This enables scaling of the production volume, but at the same time relieves employees of monotonous tasks.The problem

The components must be inserted into the mounting rail from a feeder. The problem with this is the diverse positions of the individual chain links. For this reason, the feeding of the parts was expanded to include a vibrating table.The solution

Two robolink RL-DC working in parallel use a suction pad to grip the correctly positioned component and feed it to the assembly machine. Both robots sit on a 7th axis on which they can move independently from left to right.7th axis configurator

For robots from different manufacturers

Expand the workspace of your robot with a linear module. Fast, individual and with a fixed price.Go to the configurator

Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop