Conveyor belt picking - CPR

What was needed:

conveyor belt pick & place robot with camera system

Requirements:

cost-effective and easy to integrate all-in-one solution

Material:

igus room linear robot, igus Robot Control and camera system

Industry:

cosmetics industry

Success for the customer:

coordinated solution without complex integration effort

conveyor belt pick & place robot with camera system

Requirements:

cost-effective and easy to integrate all-in-one solution

Material:

igus room linear robot, igus Robot Control and camera system

Industry:

cosmetics industry

Success for the customer:

coordinated solution without complex integration effort

Go to application

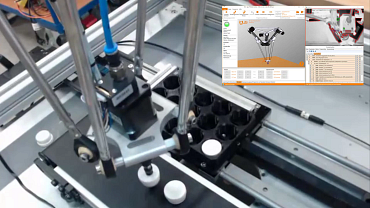

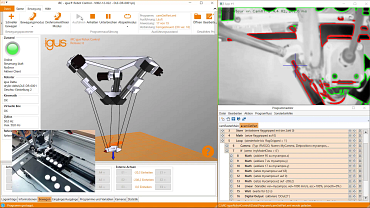

Every conveyor belt (almost) always has a delta robot.In this case, cream jars are sorted into blister packs in the cosmetics industry. A typical pick & place application at the end of the manufacturing process.

The problem

Since the jars are detected depending on their position and have to be rotated, the camera system records both the position on the belt and the position on the head. The system must be able to achieve high speed both in the detection and in the pick & place task.The solution

The application consists of a conveyor belt, a 3-axis delta robot, a camera system and the igus Robot Control, which combines all elements in the software and makes an automated pick & place application possible.Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop