Technical data:

- What was needed: A locker system in parcel stations that offers users maximum ease of maintenance

- Requirements: 100% lubrication-free and maintenance-free, quiet dry operation, mechanical resistance, easy implementation, low wear, holding heavy loads

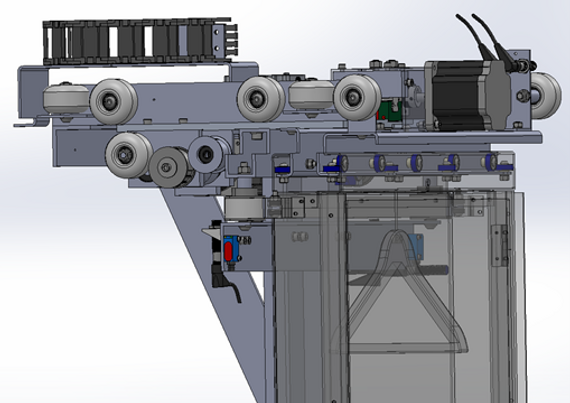

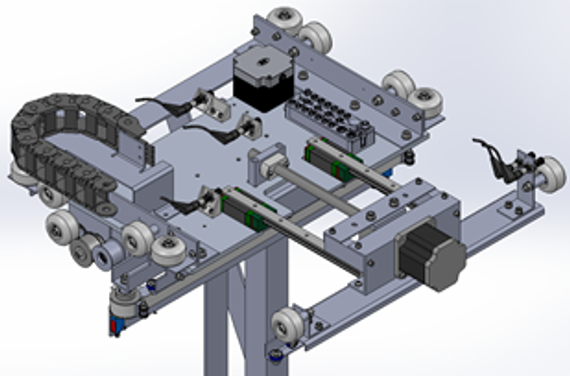

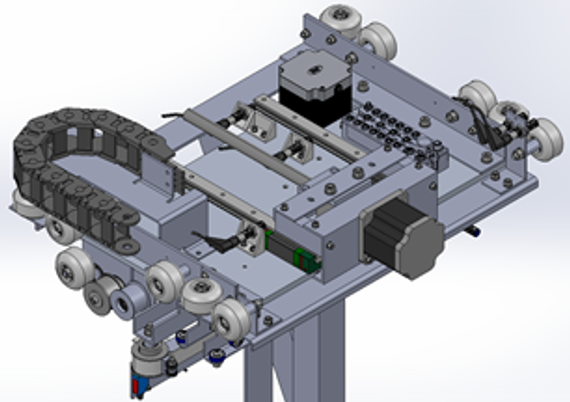

- Products used: dryspin® lead screw, drylin® linear guide, iglidur® polymer plain bearing

- Success for the customer: To offer users maximum ease of maintenance, the engineers use polymer plain bearings from igus® in the electromagnetic guidances. They allow dry, quiet, maintenance-free operation without external lubrication and are mechanically resistant. This also applies to the lead screws and linear guides used in the parcel locker opening mechanism.

Do you need more information? Contact us here

Problem

The parcel locker system is used by the general public in a variety of places, e.g. outdoors, lobbies, offices, etc. Therefore, the challenge was to enable the most instinctive use possible, so that the product fits perfectly into the user's path. In addition, a very high service rate and thus maximum ease of maintenance had to be ensured. The problems were: the simplicity of implementation, the simplicity of use over time (no grease and oil, no wear), the quality of movement (no noise, fluid) and a certain mechanical resistance (allowable loads largely dimensioned in relation to the system).Solution

The products from igus® are very suitable in this sense, as they are free of grease and oil. In addition, maintenance requires only periodic inspection. The dryspin® lead screws are installed in the SAS opening and module soldering. They provide less noise, less regular maintenance and reliability. The iglidur® polymer plain bearings are used in electromagnetic guidance and enable improved guidance and less friction. The drylin® linear guide is also installed in the SAS opening and also in the vertically motorised axis. There they can prevent noise and maintenance, are easily mounted and could convince with their size.Further application pictures:

Do you have questions about drylin® lead screw technology?

Our expert, Thorben Hendricks, will answer all your questions about dryspin lead screw technology. Just fill out the contact form, and we will address your concerns. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here