SHT-HYD hygienic design

SHT-HYD hygienic design study

... FDA-compliant adjustment ...

The drylin® drive technology meets various challenges. We continue to research into new solutions for specific customer requirements. This is how our new study on the SHT lead screw linear module in the hygienic design version was created. The goal: a linear module that meets the highest hygiene standards and is FDA-compliant.Discover the details of the study and what makes the individual components of this linear axis so special.

Contact an expert

Tech up

- Hygienic design for the highest demands

- FDA-compliant lead screw axis

- Optimised water washdown to reduce bacteria and germ formation

Cost down

- Design prevents the accumulation of dirt and thus also maintenance effort

- More quiet operation and efficiency with dryspin® high helix thread

Proof

- dryspin® stainless-steel lead screw (Ds18x4)

- Patented, tested design

- FDA-compliant materials

Sustainability

- 100% lubrication-free and maintenance-free

- Very hygienic

Impressions

Technical Govie

Structure

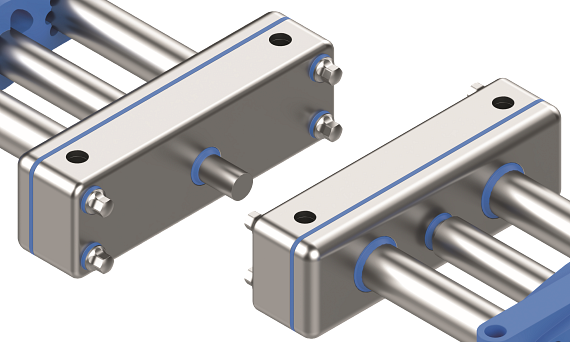

The assembly of the linear module consists of two trusses, a flushable lead screw nut, a dryspin® stainless-steel lead screw (Ds18x4) and EWMS AISI 316Ti Ø20mm guide shafts. Find out what makes our trusses and lead screw nut so special.Shaft end supports

Two holes allow the trusses to be fixed to your application. We recommend using hygienic screws and nuts here as well to completely seal the holes and prevent dirt deposits.

The rotating lead screw and shafts are sealed with specially configured wiper seals consisting of FDA-compliant HPU.

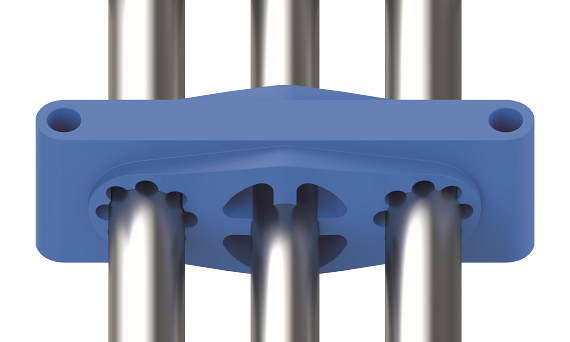

Lead screw nut

Due to the defined radii of the lead screw nuts, at least R3 is achieved. In addition, the inclines allow for better drainage of liquids and easier cleaning.

There are also through holes on the left- and right-hand sides for your connection. For this, we recommend hygienic screw connections.

Drive technology online shop

Go to the online shop

Drive technology configurator

Go to the configurator

Make a product enquiry

Send an enquiry now