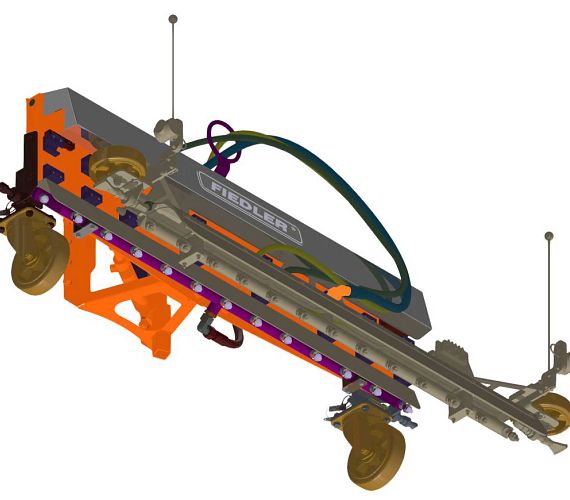

High-pressure cleaner for municipal vehicles

Cleaning with water under high pressure and swirling dirt poses enormous challenges. To meet this challenge, the German company Fiedler Maschinenbau und Technikvertrieb GmbH has developed the FSB 1.500/2.600 double spray boom, which is mounted in front of the vehicle. This innovation won the bronze manus® award in 2023. The vehicle uses side nozzles, a middle section, and electronically switchable high-pressure underfloor nozzles with high water pressure to clean floors. The engineers use a drylin® W double rail WS and drylin® W pillow blocks for the telescopic function. The vehicle is used by local authorities and municipal service providers to clean dirty roads, pavements and squares.

Profile

What was needed: drylin® W double rail and drylin® W pillow blocks Requirements: corrosion-free and wear-resistant components that are insensitive to water, spray mist, sand, gravel and brake abrasion

Industry: commercial vehicles

Success for the customer: effective cleaning of dirty roads, pavements and squares

Do you need more information? Contact us here

Problem

The FSB 1.500 standard spray boom can be equipped with telescopic arms on both sides, each of which can be extended 500mm to the right and left. The use of these telescopes increases the working area, which is an advantage when cleaning surfaces as fewer travels are required. It is even possible to clean narrow areas, such as between park benches and rubbish bins, without any problems as the vehicle can go through in one straight line without additional steering movement. However, the 500m telescope is too short, forcing users to manually rework affected areas, which is time-consuming. The aim of the German company is to double the telescopic working range. The bearings must be wear-resistant, insensitive to dirt particles and mixtures of water and dirt particles, last for a long time, be easy to replace in the event of damage, be lighter, increasing the shifting speed and reducing the force required for the motor.Solution

The double spray boom can be infinitely telescoped up to 500mm on each side. This adaptability enables the driver to clean large areas faster. Fiedler Maschinenbau und Technikvertrieb GmbH doubled the telescopic working area so that it can also clean all gaps thoroughly. To do this, the company opted for the drylin® W double rail and drylin® W pillow blocks from igus®. The corrosion-free components are not only wear-resistant and insensitive to water and spray mist, sand, gravel and brake wear. They are also robust enough to withstand severe impacts and vibrations from crossing curbs and cobblestones. At the same time, they are light enough to keep the load capacity for cleaning water as high as possible.Application pictures