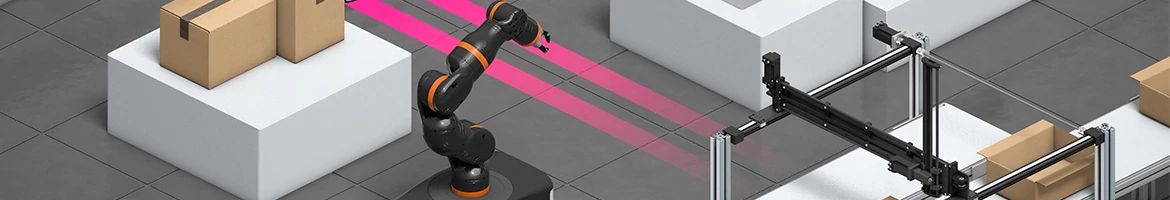

Packing robot

Efficient packaging solutions from the modular automation system

- Rapid ROI through the use of Low Cost Automation solutions

- For individual process stations or a fully automated system

- Individual and flexible automation from 2 to 6 DOF (Degrees of Freedom)

- Finished software packages that can be simulated ahead of time, free of charge

- Various grippers and complete finished solutions available from RBTX.com, the igus marketplace for robotics solutions

drylin® XXL linear robot for palletising applications

- Maintenance-free dry operation

- Resistance to dust and dirt

- Corrosion-free

- Modular system

- Plug & Play solution with the igus® Robot Control (iRC)

- Individual workspace

- Up to 60% more cost-effective than conventional linear robots

- Low assembly costs due to simple installation

App Library - Packing robots from Low Cost Automation

Flexibly expandable: automated packaging of respiratory protection masks

With Low Cost Automation, a modular automation solution for mask packaging was developed - cost-effective, quickly delivered and suitable for entry-level automation. Thanks to the modular Low Cost Automation system, the solution can be easily and quickly expanded to meet individual requirements.

Today, the Breckle company produces around one million masks per week.

Today, the Breckle company produces around one million masks per week.

To the application example

Automated contract filler for more ergonomics at the workplace

The company Fefler GmbH builds special plants for automation. For the construction of a contract filler, the special machine builder relies on a drylin linear robot system from igus. The linear robot is used for handling and packing of ready-filled bottles.

To the application example

Low-cost pick-and-place application for environmentally friendly packaging solution

To produce environmentally friendly coffee capsules of wood, a drylin® line robot is used together with a D1 dryve control system. The automated production system helps us equip up to 43 coffee capsules per minute with an exterior circumferential seal of natural rubber. Thanks to the demonstrated long service life of the components in use, the production system now operates smoothly after several millions of cycles.

The Low Cost Automation allows us as a start-up, to make the necessary investment in the corresponding production system little by little, gradually increasing our production capacity", says Julian Reitze, rezemo GmbH.

The Low Cost Automation allows us as a start-up, to make the necessary investment in the corresponding production system little by little, gradually increasing our production capacity", says Julian Reitze, rezemo GmbH.

To the application example

Automated praline picker with integrated camera system

The automated praline picker "Chocomatic" from Roose Automation, consists of a robolink® articulated arm robot that moves on a seventh axis. The flexible workspace and integrated camera system allows the robot to automatically grip pre-selected pralines and carefully deposit them in a box. All the customer needs to do is select the pralines with a mobile device.

To the application example