Excavating and grabbing with an additional degree of freedom

The L&K Land- und Kraftfahrzeugtechnik GmbH is known in the building machinery industry as a manufacturer of especially long-lasting equipment for excavators, wheeled loaders, telescope excavators and special vehicles. Numerous types of bucket, backhoe and other items of equipment are custom-made. Extremely wear-resistant Hardox types of steel – and iglidur plain bearings – ensure a long service life for the equipment, which is used in unfavourable conditions and is subjected to dynamic loads

For excavator drivers and construction machinery hire companies, they are "just" a tool - but one that has to meet the highest demands in terms of load capacity and wear resistance. This is because the shovels and clearing buckets of excavators and wheel loaders that we are talking about here dig into the material with high dynamics in each individual operation and also encounter resistance like hard rock.

The environmental conditions during this work are unfavourable, not to say extreme: the construction machines can stand in water or remove highly abrasive material. The stress acting on the tools is very dynamic and hardly calculable, especially since the equipment is also loaded on one side and is often "misused" on the construction site.

For excavator drivers and construction machinery hire companies, they are "just" a tool - but one that has to meet the highest demands in terms of load capacity and wear resistance. This is because the shovels and clearing buckets of excavators and wheel loaders that we are talking about here dig into the material with high dynamics in each individual operation and also encounter resistance like hard rock.

The environmental conditions during this work are unfavourable, not to say extreme: the construction machines can stand in water or remove highly abrasive material. The stress acting on the tools is very dynamic and hardly calculable, especially since the equipment is also loaded on one side and is often "misused" on the construction site.

Problem

The bearing point must be maintenance-free for a total of more than 4,000 hours in an application. Completely regardless of whether the excavator is standing in water or removing highly abrasive material. In addition, the bearing points are exposed to heavy loads and shocks. The exposure to dust and dirt is an additional challenge for the bearing positions.Solution

With maintenance-free and lubrication-free iglidur plain bearings, the required service life was even exceeded. Even after 5 years of use there were no complaints or the need to lubricate or replace the plain bearings, despite the highest demands. They are also around 40 percent more cost-effective than the previously installed composite bearings.Roland Georgi, designer engineer at L&K

High-quality equipment for construction machinery - "Made in Thuringia"

Many manufacturers, rental companies and users of construction machinery do not want standard tools for such conditions, but tools that are characterised by long service life and often also by special mobility and additional degrees of freedom. With this wish they are in good hands with L&K Land- und Kraftfahrzeugtechnik GmbH in Stadtilm/ Thuringia. For more than forty years, the company has been specialising in developing high-quality tools for construction machinery.The wide standard product range, which includes backhoe buckets of all kinds, high dump buckets and side dump buckets, is the basis for the most varied special designs. This is because the tools are always manufactured to customer specifications, and with a short lead time. Dipl.-Ing. Wolfgang Anderle, Managing Partner of L&K: "We deliver at short notice, usually within two to three weeks. " The modular design of the product range contributes to this as much as the modern production with CNC machines in all areas. Another important factor for the high quality and short delivery time is the know-how of the welding specialists, who are trained and further educated by L&K in its own DVS course centre.

Requirement: 4,000 hours maintenance-free operation under harsh conditions

Since about fifteen years the basic material of the L&K tools has been the extremely resilient Hardox steels of the Swedish steel producer SSAB. Similarly resistant components must also be used on the joints which, for example, tilt a high dump bucket or open and close the halves of a grab bucket.The requirement profile for such bearings is clearly defined. Dipl.-Ing. Roland Georgi, Design Engineer and in charge of Quality Management at L&K: "The bearings must achieve the same service life as the bucket. And they must be maintenance-free. “

Lightweight design counts - even for excavator buckets

Here the designers, who work with modern CAD tools, originally used metallic plain bearings with a sintered-on gliding layer. Five years ago, L&K tested an alternative to this composite design for the first time and used bearing bushings made of iglidur. This high-performance polymer with incorporated lubricant works as a "mono-material" over the entire service life without lubrication and is extremely resilient.There are three good reasons for this choice. : "The polymer bearings are about 40 percent more cost-effective. They require no lubrication and their mass is less than that of the previously installed composite bearings. " Indeed, mass plays an important role for the design engineers at L&K: "We manufacture moving components. If the bucket becomes too heavy, the dynamics suffer. For this reason, lightweight construction is also an important trend in our company, whereby the load-bearing capacity must not be impaired. “

More and more series converted

The first tests were carried out to the complete satisfaction of both the L&K engineers and the users. In the meantime, the ultra-light design, which is supplemented by iglidur plain bearings, is protected by utility patent. It is used in a wide variety of buckets, shovels and special tools - for example in high dump buckets, which are used as salt loading buckets in the salt depots of municipal utilities, and in various designs of grab buckets and trench buckets. For a high dump bucket with a capacity of 8.5 m3, L&K has already implemented a real "XXL application" for the maintenance-free iglidur plain bushings several times.Conversion without changing the design

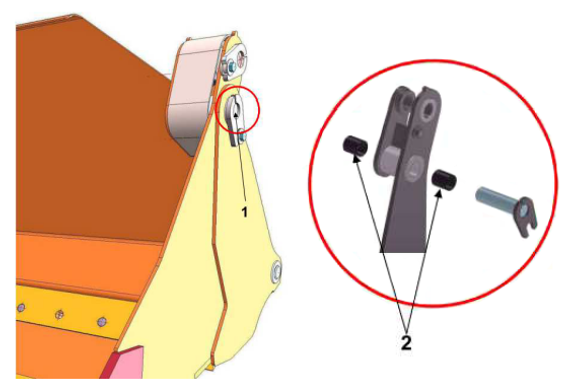

The designers of L&K use bushings with diameters of 40 to 80 millimetres made of the universal material iglidur J as well as iglidur P, which remains particularly dimensionally stable under high loads and fluctuating environmental conditions including humidity.Another positive aspect from the point of view of the L&K designers is that the iglidur bushings can be replaced 1:1 with plain bearings made of metallic composite material: An alteration of the surrounding structure is not necessary. And both purchasing and production are satisfied with the fast delivery by igus in small batch sizes: Because L&K usually only needs two bushings per tool.