Machine tending - SMTCL

What was needed:

small, compact robot unit for automated loading and unloading

Requirements:

maintenance-free, dirt-resistant, compact

Material:

igus robolink RL-DC 4-axis version

Industry:

metal processing/CNC

Success for the customer:

thanks to the very compact robot, the process could take place in the machine's installation space

small, compact robot unit for automated loading and unloading

Requirements:

maintenance-free, dirt-resistant, compact

Material:

igus robolink RL-DC 4-axis version

Industry:

metal processing/CNC

Success for the customer:

thanks to the very compact robot, the process could take place in the machine's installation space

Go to application

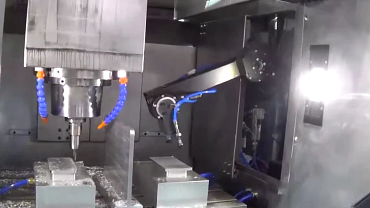

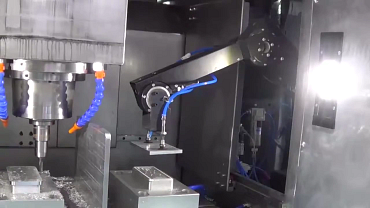

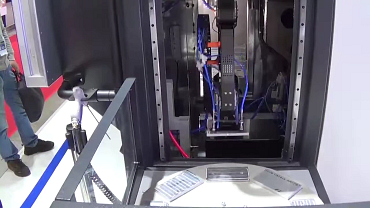

In all manufacturing industries there is a point at which material has to be brought in and also taken out again. To ensure that there is as little manual failure as possible and that injuries are avoided, SMTCL relies on automated solutions. In this case, the bar stock of the workpiece is brought in, machined with a milling machine and then removed as a finished workpiece.The problem

The customer was looking for a very compact and maintenance-free robot variant that could be integrated directly into the machine. In most applications, loading and unloading processes are carried out with robots outside the machine. Not so in this particular case. The freedom from maintenance and the dirt and dust resistance of the robot were important for this.The solution

A structure with a 4-axis robolink DC robot arm in combination with a suction pad.The robot places the raw material on a turntable which then guides the material to the tool. In exchange, the finished component from the previous process step is transferred from the milling machine to the robot. The latter removes the component and supplies raw material again.

The robolink configurator

Discover our online configurator

With our intuitive online configurators, you can create your own robolink articulated arm robot with just a few clicks. Fast, individual and with a fixed price.Discover the unlimited freedom with our tools now.

Go to the configurator

Low Cost Automation shop

Cost-effective robotics for your automation project

You can find the right robot for your individual application in our online shop.Browse, get information and order easily.

To the shop